In this article, the author of the channel 1000 DIY and TIPS will repair a dripping faucet, or rather, repair crane boxes.

Someone will say that it’s easier to buy a new one, and in its own way it will be right.

The author appreciates the time more, because the repair of the crane axle box will take less than five minutes, and the trip to the store for more than an hour. In addition, for going to the store you will have to dismantle the inoperative crane-axle, otherwise you will not pick up the right one. After spending a couple of minutes reading the article, you can fix your faucet without any help.

Materials and tools.

A Phillips or hexagonal screwdriver depends on your crane.

Adjustable wrench or pliers.

Vinegar or citric acid.

1.6mm copper wire

Rubber gasket, or 6mm thick rubber

Just a little bit of theory for those who first fix the tap, and the author will begin to practice.

How to find out which crane axles you have?

By the number of revolutions of the valve.

Ceramic box crane, unlike a worm crane, makes only a quarter of a turn.

It stops dripping if you press on the valve from above.

The worm gearbox can make more than one full revolution around its axis, and stops dripping when you close the valve with force.

In a ceramic, the author will change the fluoroplastic ring to a home-made ring made of copper wire.

At a worm crane box changing a lining.

The gasket can be bought, or cut out of rubber with a thickness of 6-7 millimeters.

The most budgetary and quickest repairs can be done simply by turning over the old gasket.

If it is crackless, it will work.

To begin with, the author blocks the water.

The procedure for dismantling the ceramic and worm crane boxes is similar.

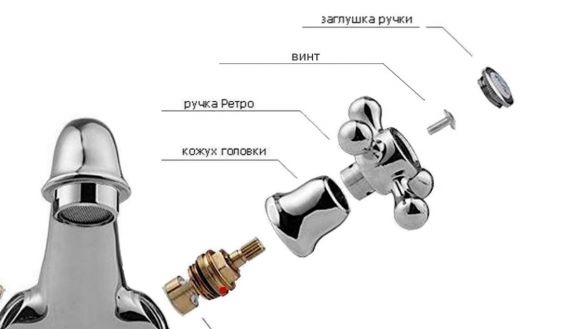

Unscrews and removes the valve. The bolt will hide from above or from the side.

You may have a screwdriver screwdriver. The author has a hex key.

After that, unscrews the decorative skirt. Do not crush or scratch much, perhaps you have it from plastic.

Under the skirt there will be faces under the wrench.

If you do not have such a key, grab the edges with pliers and twist counterclockwise.

Then everything is simple, if you have a worm crane, change the gasket as described above.

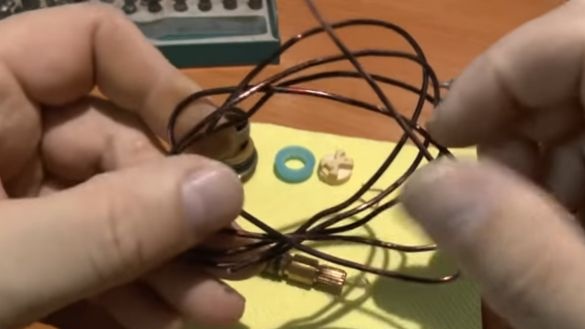

If ceramic, you will need a small piece of copper wire with a diameter of at least 1.6 millimeters.

Removes silicone pad.

Then two ceramic plates.

Further, with something sharp, removes the circlip.

Sometimes they rot and break, it's not scary.

And pushes the inside out. Easy to go.

Ceramic crane boxes are very reliable, but they have one weak point.

Here is the PTFE washer.

Over time, it wears out, becomes thinner, as a result of which the clamp weakens and the tap starts to flow. The author will make a new washer from copper wire. The wire he found was almost two millimeters in diameter. And it takes about 1.6mm. 3-4 dozens can be removed with sandpaper, or a regular knife.

He bites off a piece of wire and bends the ring, right on the crane box.

It is difficult to bend short pieces of wire; take a wire with a margin.

Here is such a ring.

Now he takes the wire cutters and bites off both ends with one movement.

Then it shortens the ring by one or two millimeters, so it will be better to fall into place.

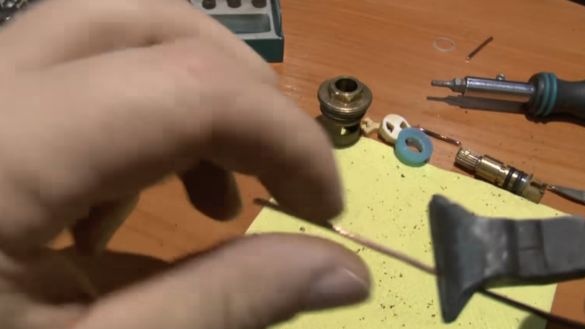

If there is a lot of lime on your crane box, disassemble and boil everything in citric acid.

Or soak in vinegar, and they will become like new.

If the author puts the ring on here and starts collecting, it will not go in.

Therefore, first lowers the ring inside the sleeve.

Everything that comes into contact with the ring is lubricated. The author has some lithol.

Tries to dress. Does not go, the ring rests against the gum.

Slightly unbends the ring and lubricates the gum.

Tries again. Happened.

Replaces the snap ring. If the ring breaks, collect without it. The crane will not flow.

Now puts ceramic plates in place.

The first grooves getting into focus.

And into the slot for the second.

fixes them with a silicone gasket.

That's the whole repair. The axle box will no longer flow!

Thanks to the channel 1000 DIY and TIPS for detailed instructions. I also repaired the axle boxes myself, but a little bit wrong.

I made a lining between the first plate and an emphasis from 2-3 layers of an insulating tape, figuratively cutting it. It’s also a working method, but it holds up to a year, then it is necessary to change the electrical tape again.

All good homemade!