In this article we will look at how to make a machine using a jigsaw as a basis. With the help of such a machine it is possible to process small wooden and metal parts. For the manufacture of the machine the master needed the following

Materials and tools:

- Electric jigsaw;

-A screwdriver;

- Canvas for jigsaw;

-A circular saw;

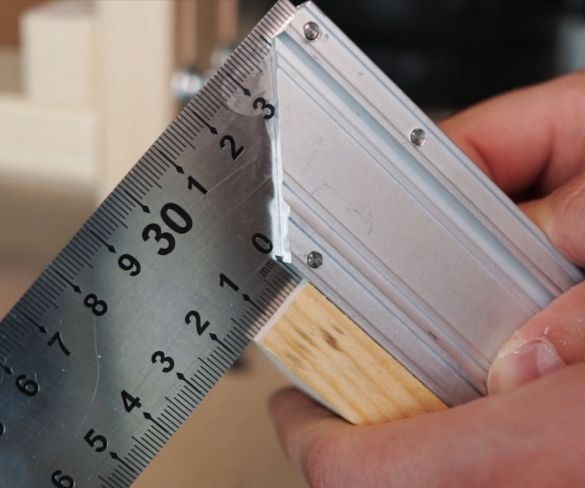

-Gon;

Milling cutter;

-Vacuum cleaner;

- Clamps;

-Roulette;

-Board;

-Plywood;

-Fork;

-Installation box;

-Wheels;

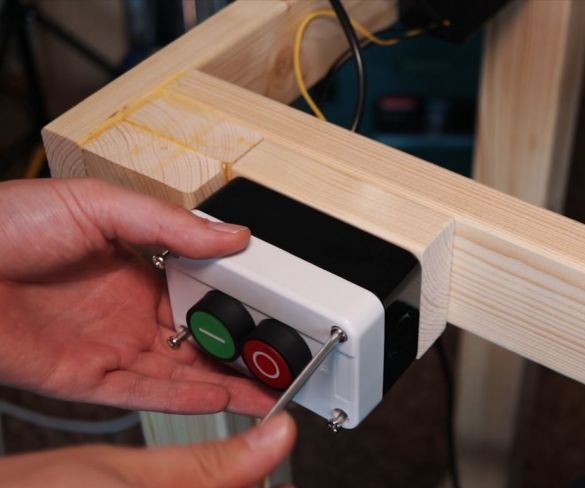

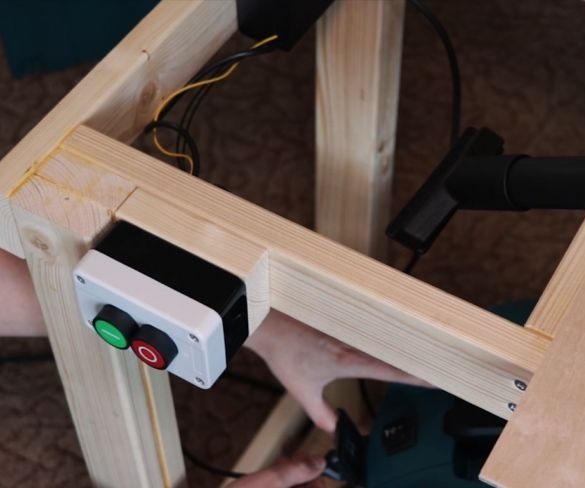

-Dashboard with buttons on / off and emergency off;

-Bearings;

-Fasteners;

- Sewer accessories;

-Glue;

-Sandpaper;

-Polyurethane varnish;

Expanded polystyrene;

-Bicycle camera;

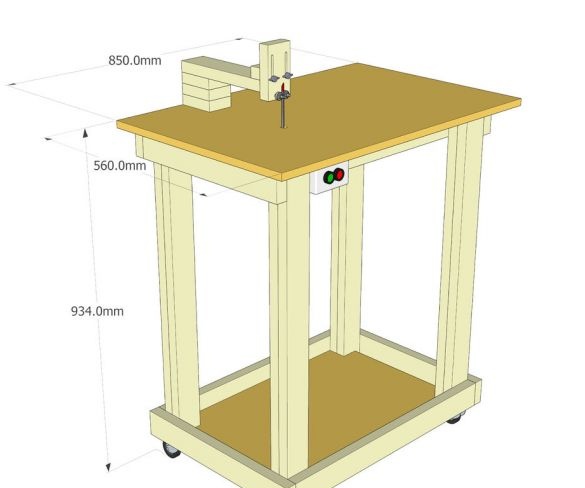

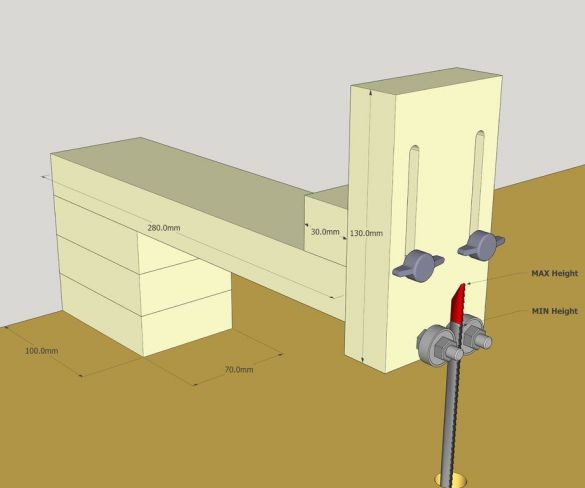

Step One: Project

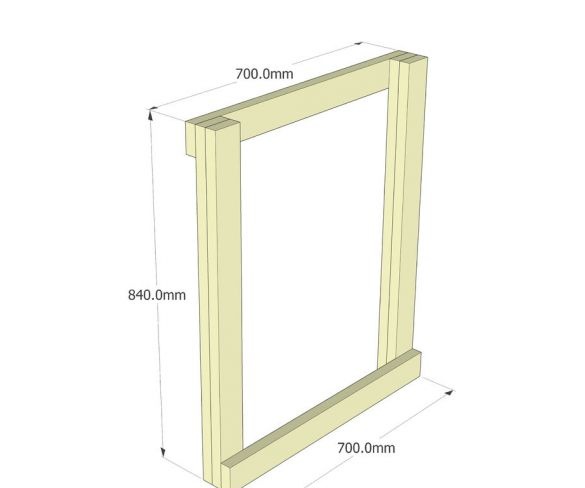

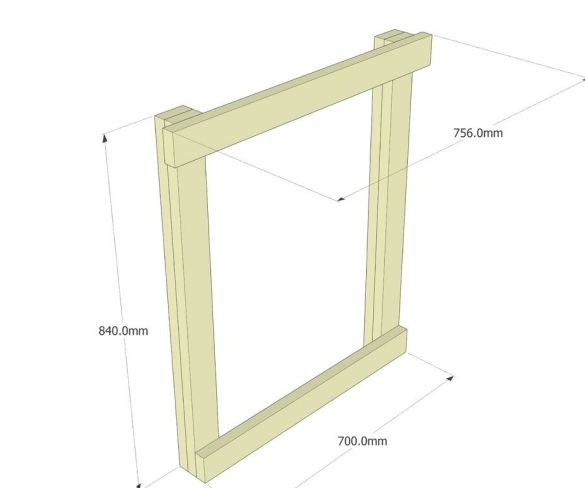

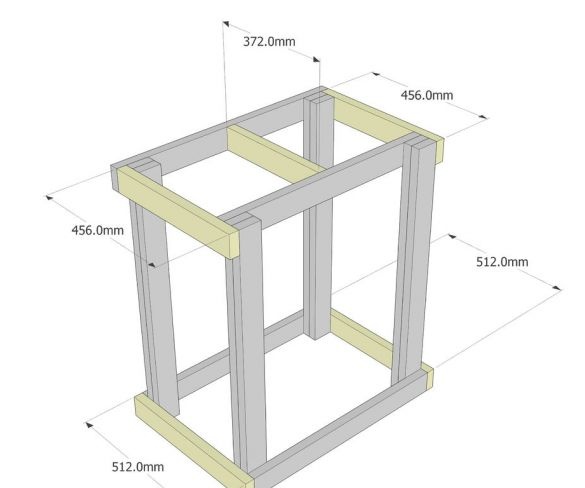

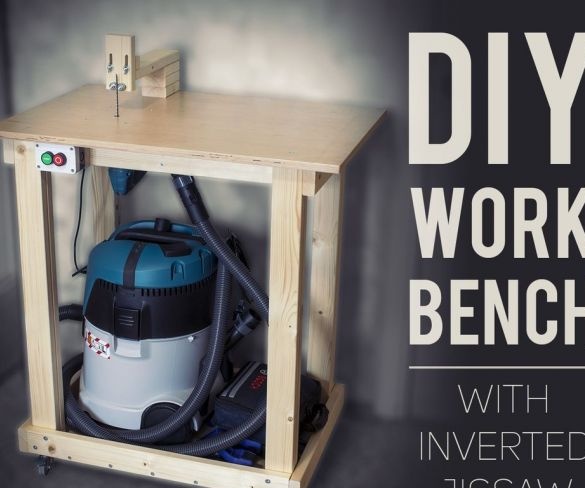

It all starts with a project. The machine measures 943 * 560 * 850 and consists of three parts, a table, a jigsaw and a dust collection system. You can download the file with drawings by clicking on the link.

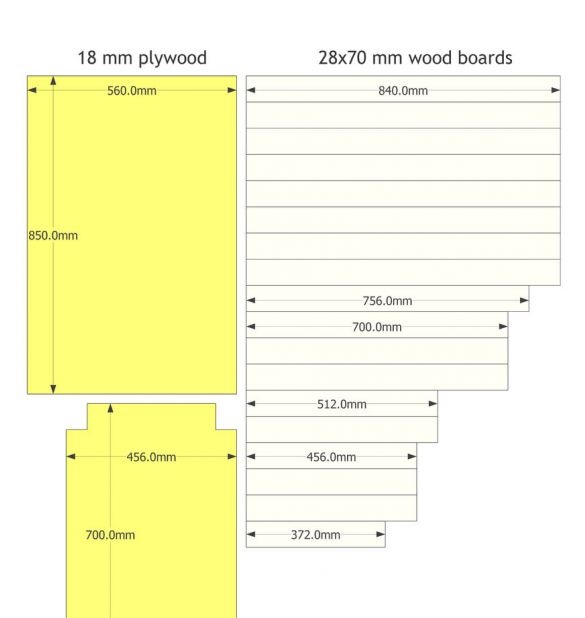

Step two: procurement of parts

To make a table, you need to prepare the right amount of parts.

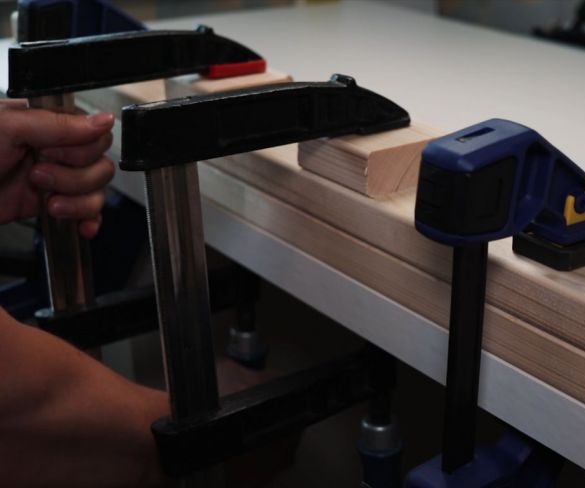

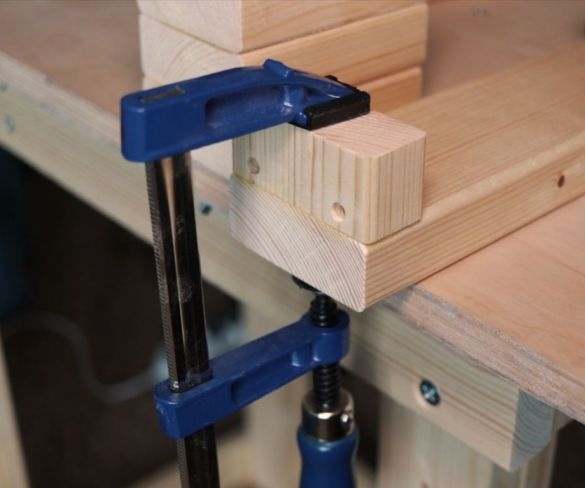

Step Two: Assembling the Table

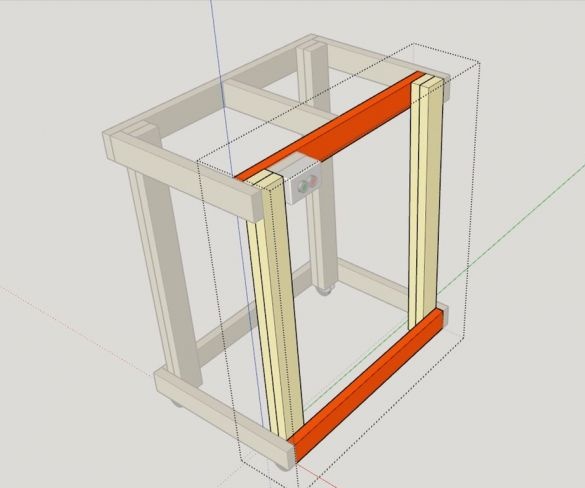

For four table legs, the master glues two pieces together.

Assembles the front frame of the table.

Gathers the back.

Gathers all parts of the table together.

Step Three: Cover

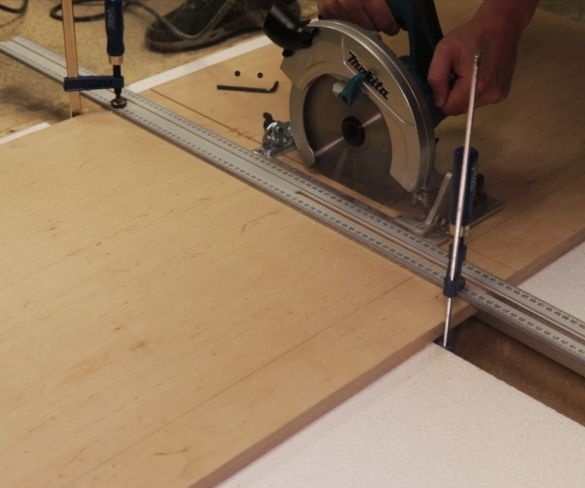

Now you need to make a table cover. The master cuts the lid out of plywood.

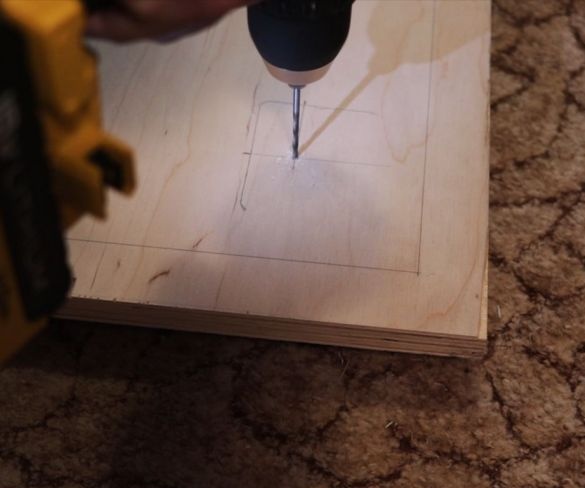

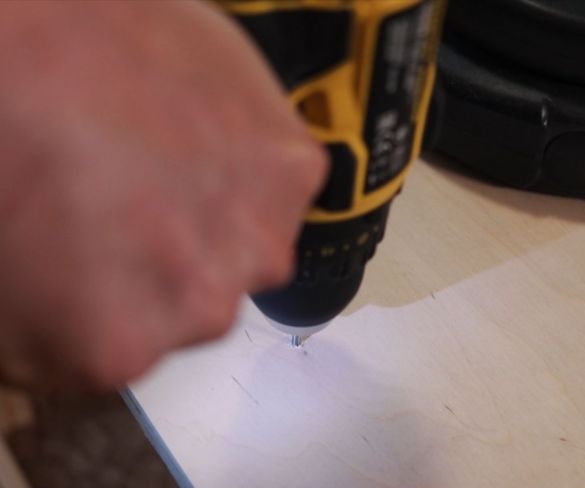

Drills holes in the corners for attaching the cover to the table.

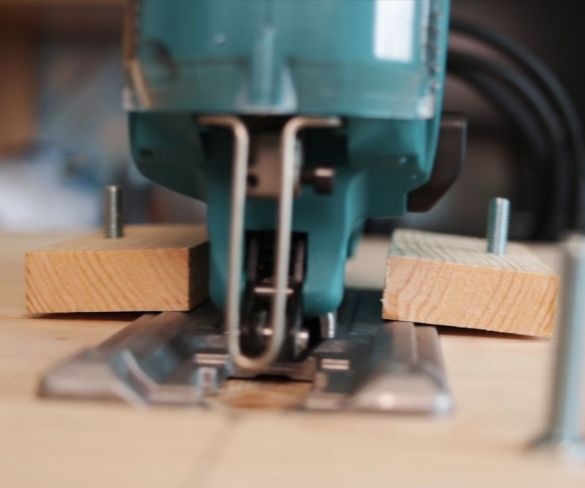

Further in the lid you need to choose a niche for installing a jigsaw, a hole for the blade and holes for attaching a jigsaw.

Niche master makes a cutter at the bottom of the cover.

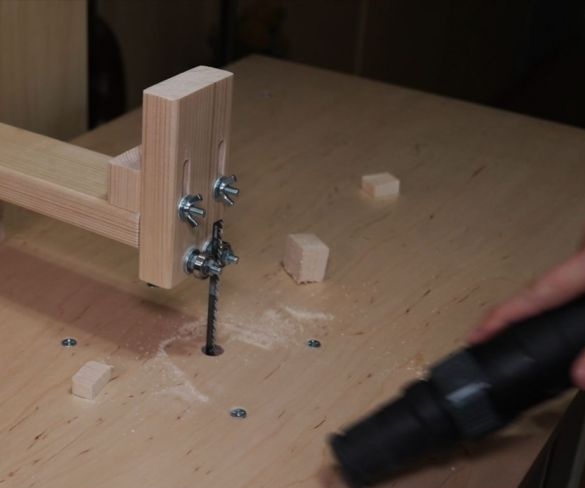

Drills a hole for the blade and jigsaw mounts.

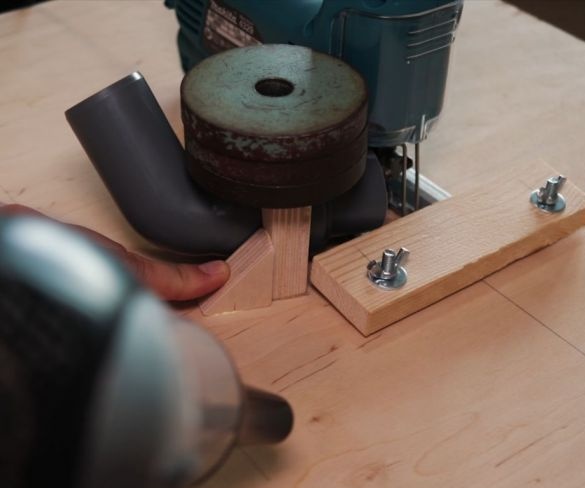

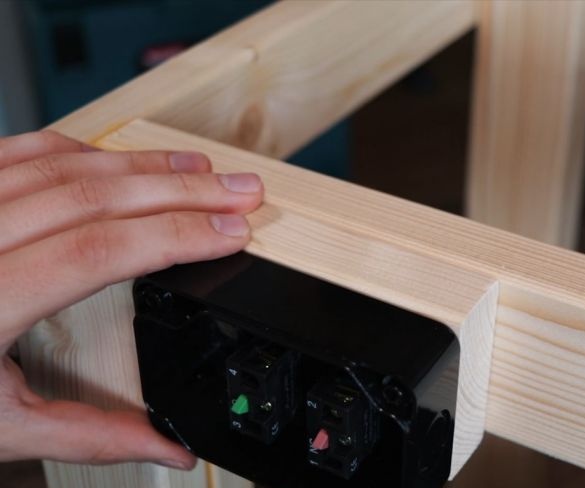

Step Four: Dust Collection System

To collect dust, a vacuum cleaner is installed at the bottom of the table, from which a pipe is brought to the desktop.

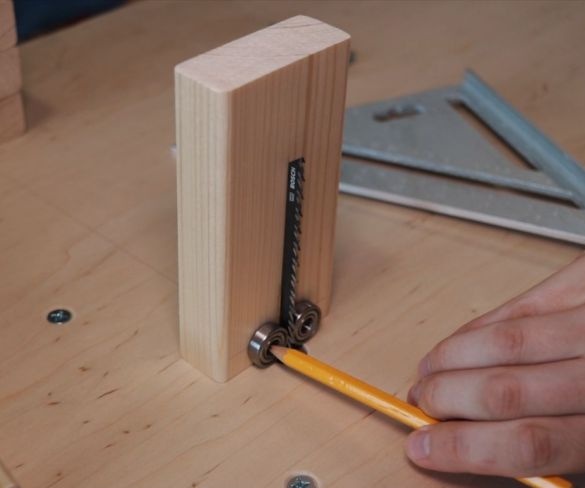

Step Five: Guide

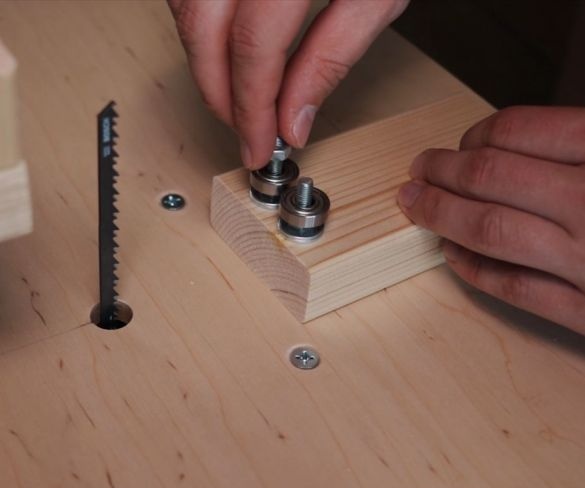

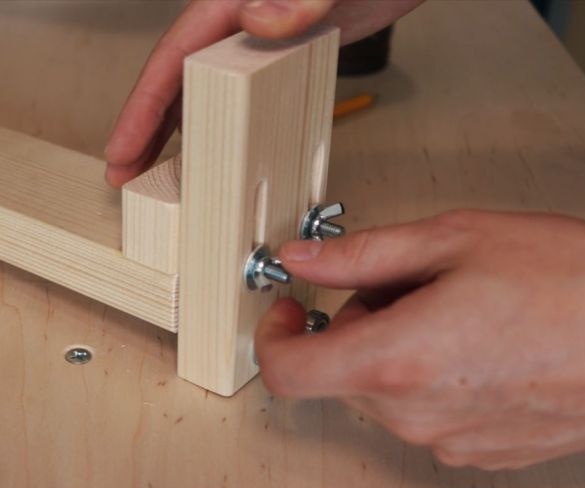

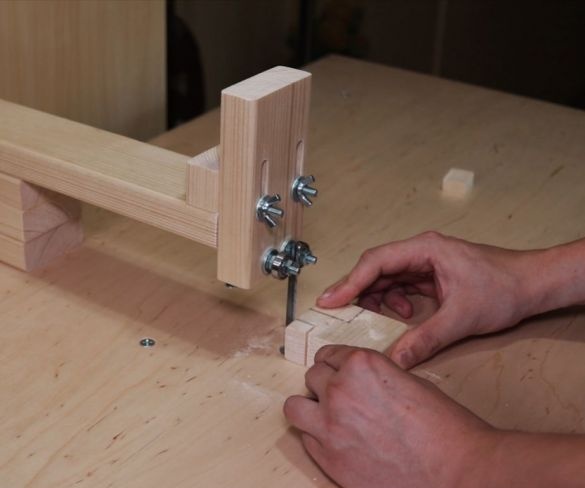

To support the canvas, the master makes a guide.

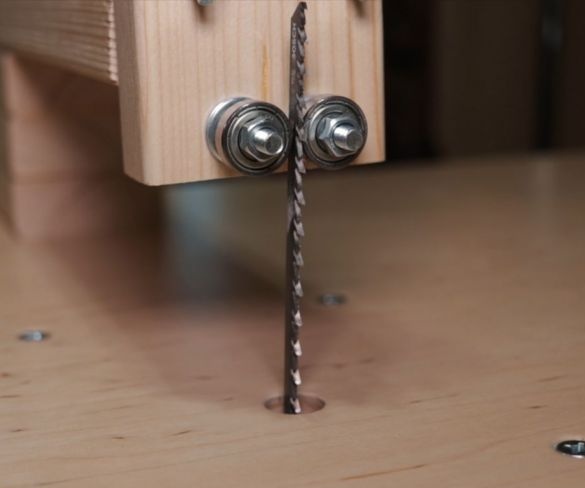

The blade will slide between the two bearings.

To replace the canvas with a larger or smaller (in length), the master makes it possible to adjust the guide height.

Step Six: Lower Shelf

From plywood cuts the bottom shelf.

Fastens her.

Tightens the wheels.

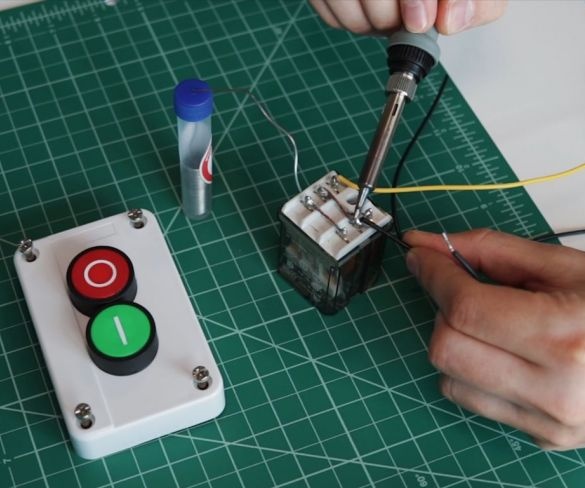

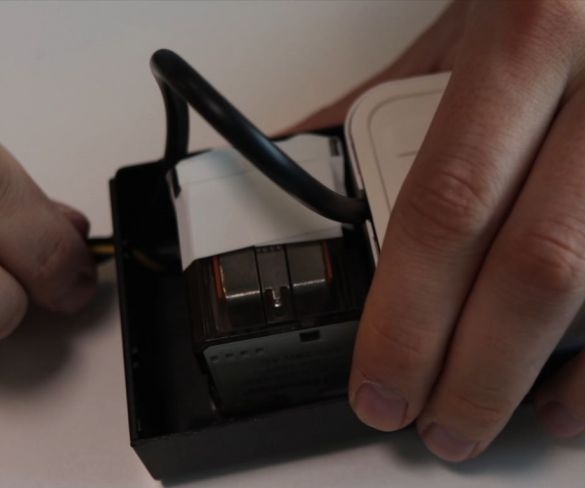

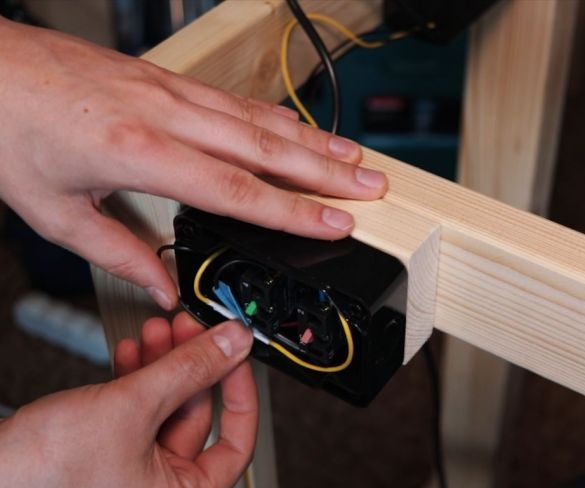

Seventh step: electrical part

Performs installation of electrical parts. The layout of the machine is simple.Vacuum cleaner and jigsaw are connected to the mounting box. From the box, the wire goes to the on / off buttons and to the power supply. When you press the power button, both the jigsaw and the vacuum cleaner are simultaneously turned on.

Step Eight: Grinding

The master polishes the sharp corners of the table and covers the lid with varnish. To reduce vibration, between the cover and the table, the master fixes the rubber.

Screws the lid to the table.

The machine is ready.

The whole process of manufacturing the machine can be seen in the video.