A powerful camping knife is a very useful tool if you need to wade through thickets, chop something, stab, plan, cut and so on. This knife will allow you to survive in the wild, if you have survival skills. However, such a knife will be useful to both the fisherman and the hunter, or simply to the summer resident. It is ground to a razor condition, they can not only chop, but also finely chop vegetables, fruits and so on. The knife looks stylish, it is reliable and durable.

To make such a knife, you will need good steel. Metal is needed with a knife, which can be hardened and sharpened to the desired value. Various tool steel was well suited. But we will need a workpiece of rather massive dimensions, so it makes sense to buy a ready-made piece of metal. The author uses 01 grade steel in the manufacture of his knives. This steel is easily hardened in home conditions, it has excellent hardness in the region of 60 units, and almost does not rust, since it contains chromium and other alloying additives. Such steel is actively used by many masters of foreign countries. So, we will consider in more detail how to make a similar knife.

Materials and tools used by the author:

Material List:

- steel 01;

- textolite, plastic (or similar for linings);

- epoxy adhesive.

Tool List:

- belt sander;

- polishing machine or belt for a grinder;

- tape cutting machine;

- drilling machine;

- blacksmith furnace and other tools for hardening;

- paper, pencil and other accessories;

- clamps, spray can, etc.

The process of making a knife:

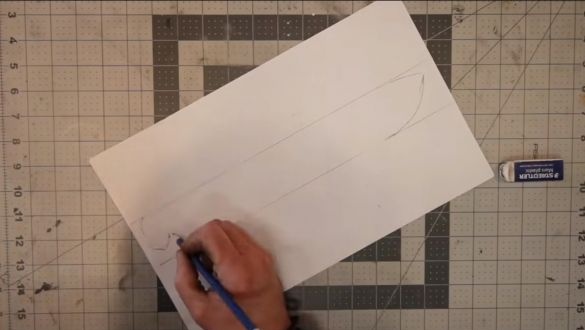

Step one. Cut the main profile

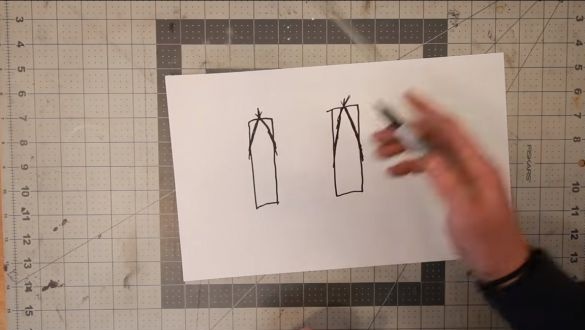

It all starts in the manufacture of knives the same way - you need to develop and cut out the desired knife profile from paper. If you have a problem with this, you can download the finished profile from the Internet and change it at your discretion. For example, on Pinterest you can find a huge number of knife designs.

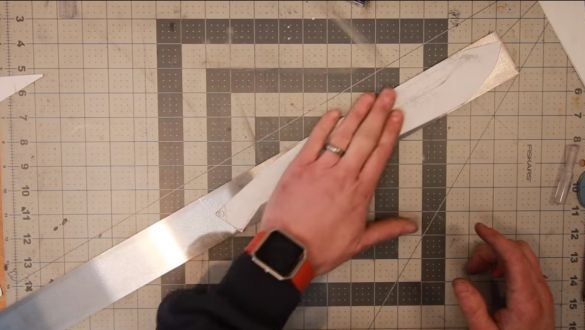

To make everything simple and quick, the author pasted a template from paper onto the blank, and then painted over the open metal with paint from a spray can. Well, then we proceed to cutting, it is most convenient and fastest to work on a tape cutting machine. After cutting, it remains to grind the product along the contour to smooth out all the bumps remaining after cutting. For these purposes, the author uses a belt sander.

Step Two Blade groove

Our knife must withstand heavy loads, as they are supposed to chop. To make the blade tougher, the author makes a groove along the blade. Thanks to it, we get a stiffener in the upper part, which will not allow the blade to bend. The author makes a groove on a belt sander. We make all the necessary measurements and proceed to grinding.

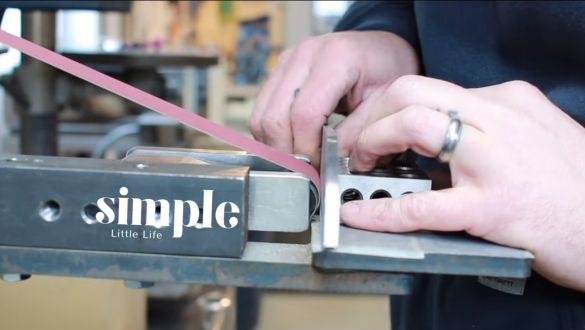

Step Three Bevels and bow

You can start the formation of bevels. At the same time, do not forget that you do not need to sharpen the knife before hardening, as thin metal can lose alloying additives and steel will turn into a regular "raw". Usually, craftsmen leave a blade thickness of at least 1 mm.

We draw the center line along the blade and proceed to grinding. Thanks to this line, you will remove the same amount of metal from all sides. If you do not have a special tool, look for a drill of the same diameter as the thickness of the workpiece.

Gently, slowly, we form bevels on each side.

The author also thought and formed the desired shape of the bow of the knife.

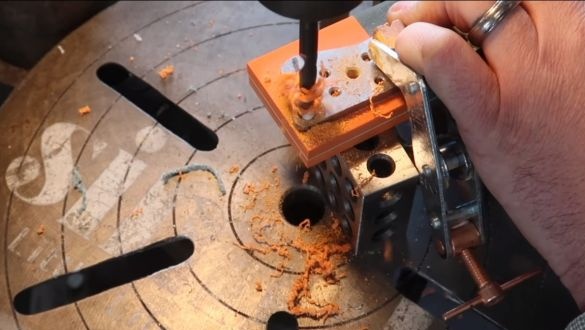

Step Four Holes and strategic cloves

In the handle we have to drill holes for the pins, they will hold the pads. In addition, the author drills many holes in the handle area. They will be needed in order to lighten the handle a little, as well as for a more reliable bonding of the pads. By the way, in such knives, the nose should always be heavier than the handle, while the force will be distributed correctly. That is, the knife will be chopped like an ax.

Also, the author uses a special file in two places to form denticles on the knife. They will be needed if you need to grind something, polish it and so on. When the metal is hardened, these cloves will become very durable.

Step Five We make pads

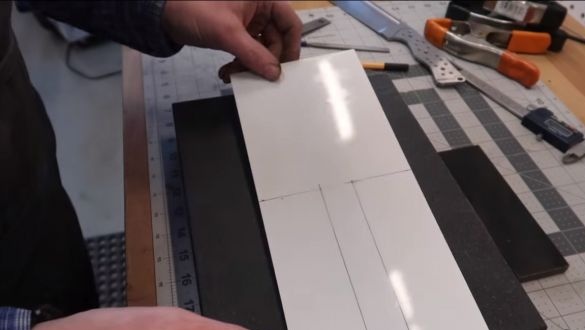

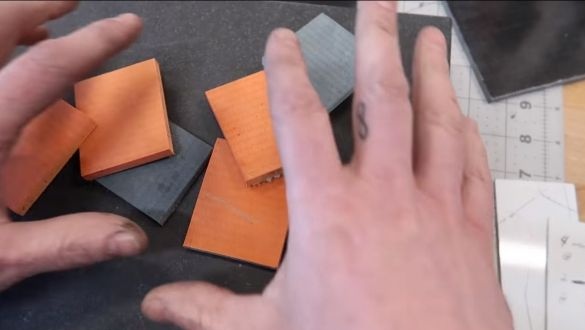

Now we need to make the pads. At the author they are combined and consist of three materials. In appearance, this material resembles textolite and some kind of plastic. The advantage of synthetic materials is that they are not afraid of moisture, durable, do not require impregnation, such handles last a long time.

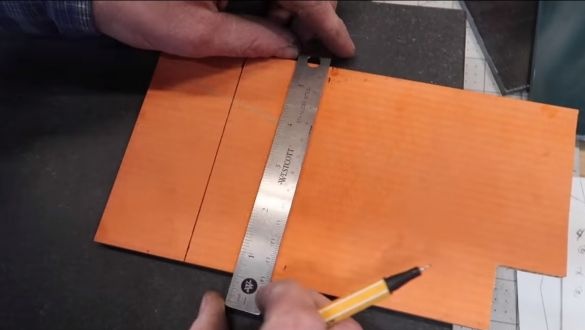

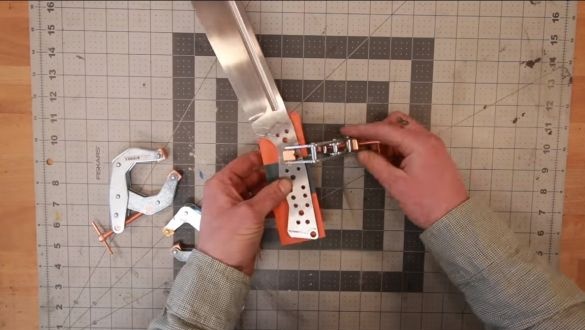

We take the main thin sheet plastic and cut out the desired blank. Next, three parts are glued to this base using epoxy glue. We carefully compress the whole thing with clamps and let it dry. Of course, before gluing, all the parts are carefully adjusted to each other on a belt grinder. When the glue dries, we grind the resulting workpiece on a belt grinder.

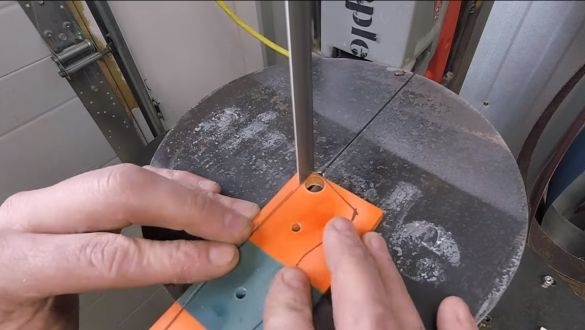

There is material for the pads, now we attach the knife handle to it and drill holes for the pins. Well, then we outline the contour and cut it on a tape cutting machine or a jigsaw. We carefully grind the resulting pads, we form the desired profile.

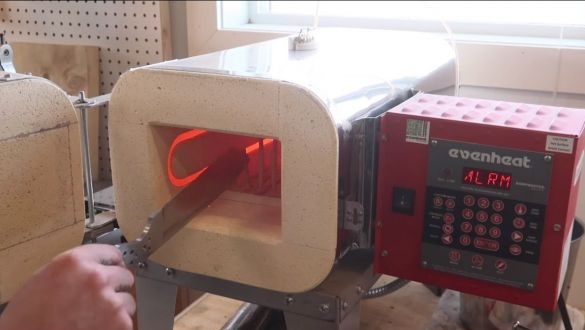

Step Six Hardening and cleaning

To harden steel 01, we send the blade into the furnace and heat until red. For hardening, each steel grade has a certain temperature regime and conditions. We bring a magnet to steel, if it does not react, then the steel is sufficiently heated, but this is only an approximate way. Next, immerse the blade in oil. Hardening should be successful, check it. We take a file and try to scratch the blade, if there are no scratches, then the steel is hardened.

Now the metal has to be let go, as it is very fragile. We warm the blade in the oven for about an hour, and maybe 1.5 hours, since we have a rather large knife. The temperature should be 200 degrees. Then turn off the oven and let it cool with the knife in the closed state. The metal should become a straw color if the vacation was successful. That's all, now we have a blade of excellent quality that will not crumble when cutting.

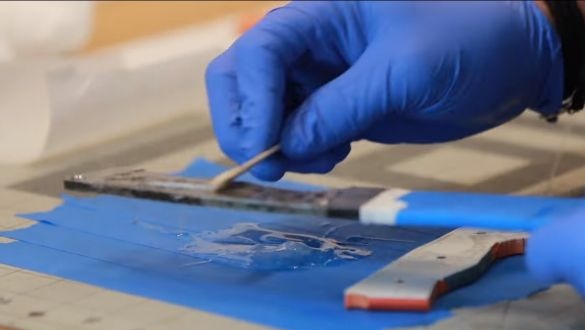

After hardening, thoroughly clean the metal from the oxide. Do it manually using fine sandpaper. And so that the metal is well polished, we wet the sandpaper with water or a special cleaning agent.As for the holes, they can be cleaned with a rolled up piece of paper or a drill. Holes are important since there must be good contact between the adhesive and the surface. Finally, we polish the metal on a polishing machine.

Seventh step. Pen assembly

The handle can be assembled, for this we need pins and epoxy glue. We glue this whole thing and clamp it with clamps. We wait for the glue to dry and finally grind the handle on the tape machine. At the end, the handle can be polished. This material does not need additional processing.

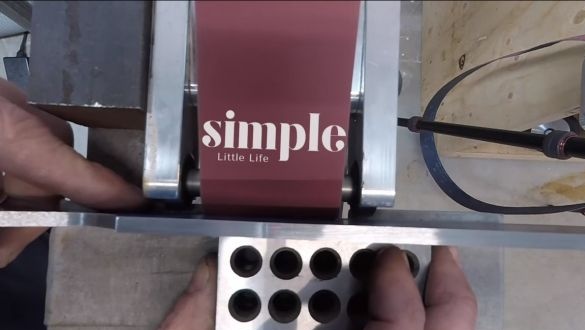

Step Eight. Completion

That's all, the knife is ready, we will sharpen it to the state of the blade. To do this, you will need a belt sander with a fine-grained belt. Belts with diamond chips are well suited. The author’s knife was so sharp that it easily cuts a newspaper canopy. That's all, homemade ready, I hope you enjoyed the project! Good luck and creative inspiration, if you want to repeat it!