In this article, the Lefty channel will show the whole process of creating a lock with a secret.

The author will make a small padlock, it is easy to open, but you need to guess how.

The author will make some of the details himself, and part will be taken from a ready-made, purchased lock.

The body will be made of aluminum ingots.

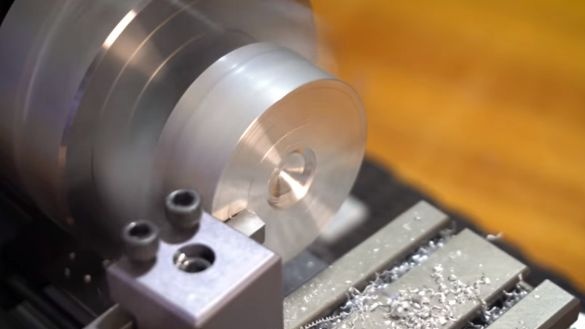

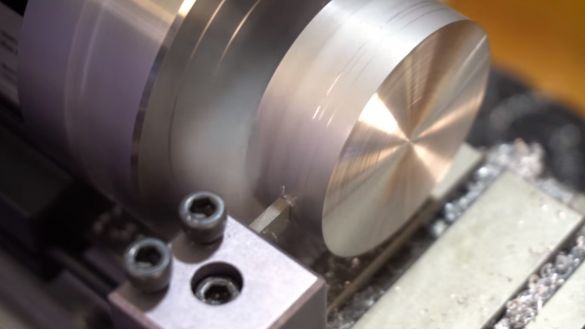

The uneven edge of the blank is grinding.

It will consist of two parts, with milling inside.

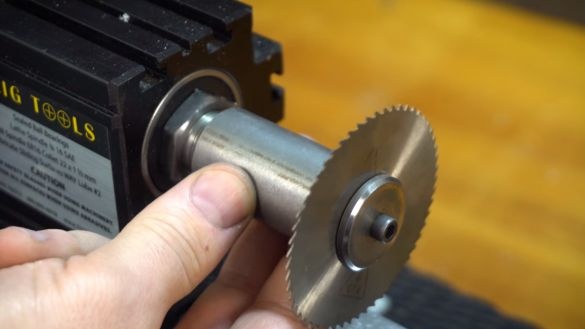

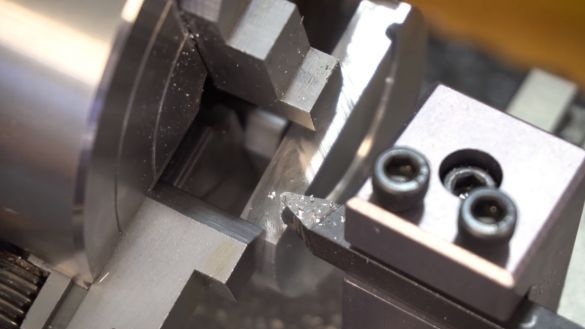

From the side of the future bow, part of the body must be cut off. For this, a disk mill is installed.

A milling superstructure is also installed.

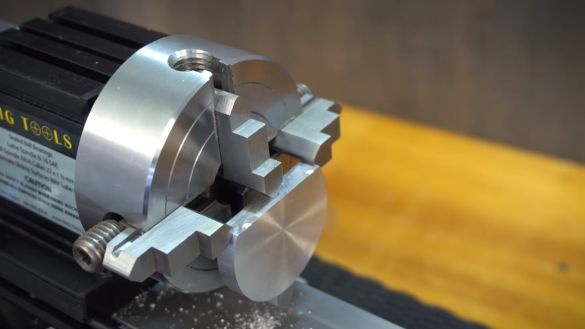

In the add-in, it clamps both halves at once, because they must be the same.

And cuts off.

The end mill marks the places where it will be necessary to grind a groove for the arch.

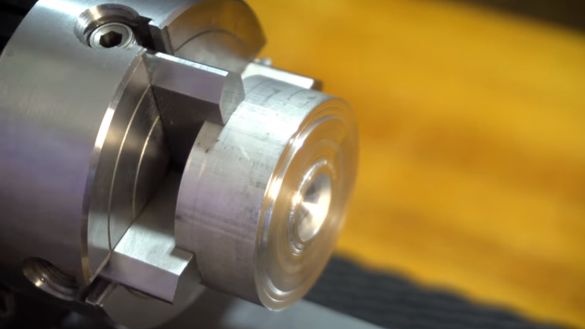

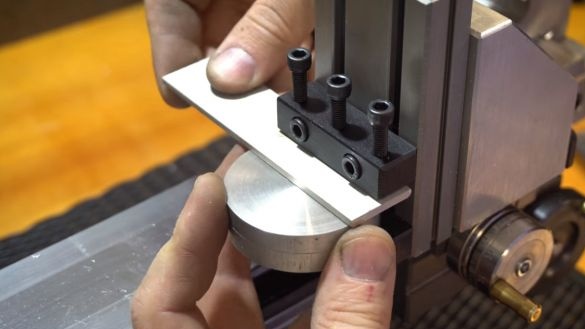

In a cartridge with independent cams, the part can be shifted relative to the center.

In each half of the body, a groove is pierced by half the diameter of the arch.

And trying on a bow.

When the lock is closed, it seems that the handle has a standard U-shape.

The author traveled around the city floor and found such a welded stainless steel ring.

It must be carefully cut at the place of welding.

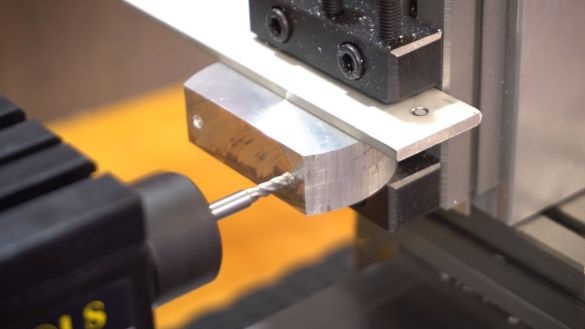

It was not so difficult to disassemble a store padlock. It is necessary to drill several holes from the end.

After that, the entire mechanism is removed from there.

From the purchased castle you just need a larva. This is the part into which the key is inserted.

And for her, a hole is drilled in the bottom of a new building.

The key hole in this case is only required in order to confuse the cracker.

And the remaining details of the mechanism are essentially not needed. Therefore, the back of the locking mechanism - the larva - is drained.

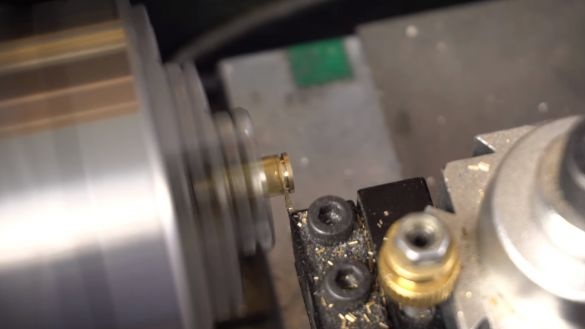

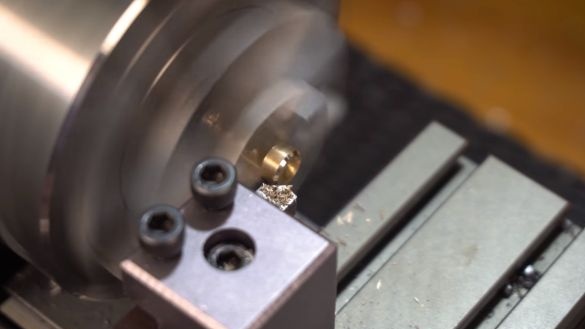

For the stopper, in the back of the larva, an annular groove is pierced.

In one half of the body, a recess is milled into which the stopper will engage.

It is needed so that the larva does not fall out, but rotates, thereby simulating the operation of the mechanism.

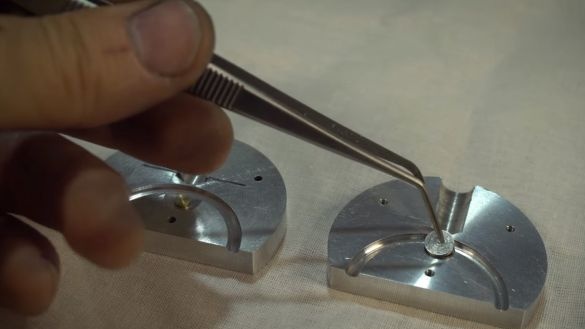

Trying on the larva to the stopper.

And in this place there will be a real locking mechanism. But it will be completely hidden in the case.

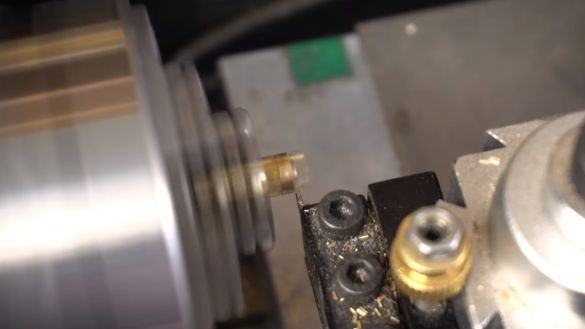

A part is turned out of the metal that is magnetized, which will be a stopper for the bow.

Establishes a spring and a stopper in their place.

The most difficult moment here was to pick up a spring of necessary rigidity. Closed state.

Under the influence of the magnet, the spring is compressed, and the stopper sits lower.

Then the bow - the ring rotates.

In the key, drills a hole for the diameter of a small neodymium magnet.

Replaces the magnet. Thus, the key will perform its direct function.

The author trims the larva a little.

And he drills holes for the screws holding two halves in the body.

It cuts the thread, checks all the holes so that there are no displacements.

Of course, the body could be welded and glued. But this is still a decorative thing, so the author used small cogs.

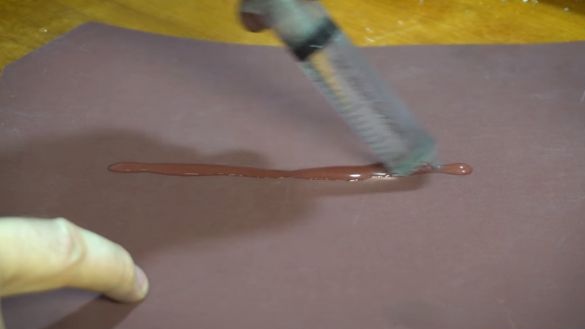

Next, takes sandpaper, which must be used with water.

And polishes both halves of the case.

The emery paper is fine-grained, therefore it is polished for a rather long time.

Now the assembly process. The author makes it beautiful and neat.

It remains to insert and tighten the screws.

If desired, can be varnished, or painted. All is ready.

It remains to test. The first thing that comes to the head of a person who tries to open it is to insert a key into the keyhole.

But no matter how much he turns the key, the lock will not give in.

Even if he realizes where and from which side to put the magnet, it will still be necessary to understand that the handle is not pulled out, but rotated.

It turned out such a working decorative thing.

You can play a trick on your friends by making them a puzzle, and even by handing a key.

The manufacturing process of this exclusive castle, and the castle itself was created by the Lefty Canal.

All good homemade!