In any work, especially physical, you need a strong reliable grip. And his training can begin with simple actions. Such as opening and closing doors. But if, in essence, there is nothing to grab at, then there is a high probability of remaining at the initial stage of development. To avoid this, you need good, comfortable door handles that you can make yourself.

As one of the options I propose my own version.

Tools and materials used:

Instruments:

1) wooden mallet;

2) a chisel;

3) manual planer;

4) a semicircular file;

5) a metal square;

6) metal ruler;

7) black lead pencil;

8) a hacksaw for wood;

9) electric jigsaw;

10) clerical knife;

11) scissors;

12) sandpaper;

13) bench vise;

14) planer-circular machine;

15) eccentric sander.

Materials:

1) a board 65 cm long, 12 cm wide, 3 cm thick;

2) thick paper for the template.

Manufacturing process:

Step 1. Cutting the pattern.

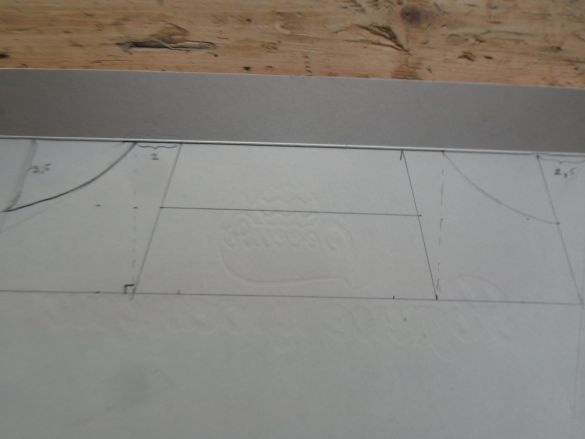

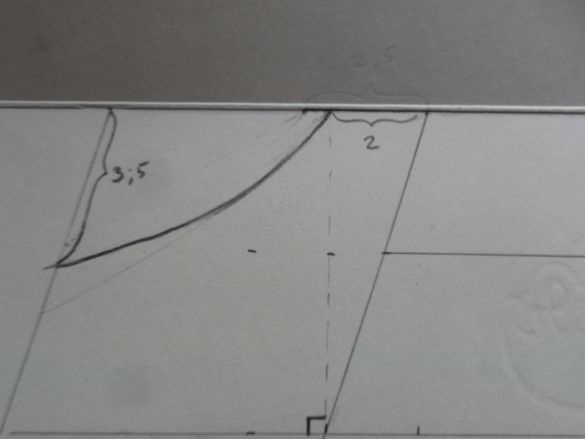

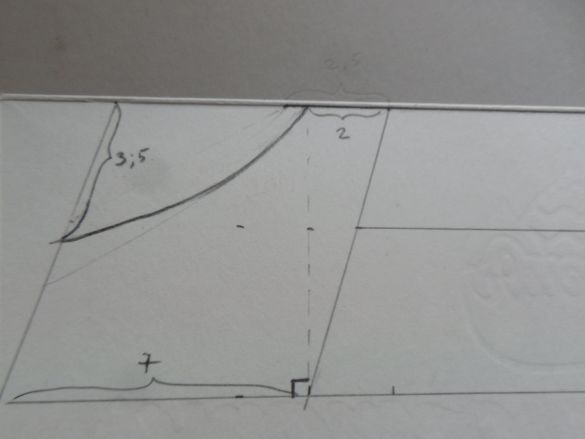

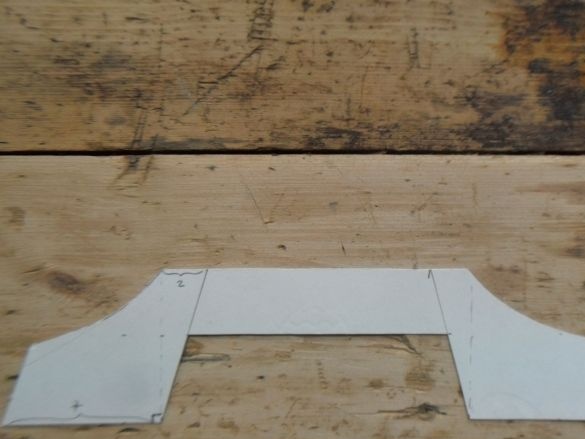

To facilitate and speed up the work in serial production of pens, you should first make a template. For this, a lid from the box for sweets is suitable. We extend the side walls, we retreat 7 cm from the upper bend and draw a parallel line. Next, we draw according to the chosen sizes the lateral and central straight lines, as well as two curved lines. The result is a pattern in which the length of the handle is 28 cm and the width of its girth is 3 cm.

The finished drawing is cut out with the help of an office knife and scissors.

Step 2. Sawing the board.

We plan the board from four sides. Since the height of the handles will be equal to 7 centimeters, we set the emphasis on the machine at a distance of about 2 cm from the saw blade. The side rough side of the part of the board we need is stitched.

Step 3. Stroke the template.

From the resulting workpiece you get two pens. The photo shows that there are knots on the board, which, if you put the template in a certain way, can “get” to the cut points or to the narrowest places of the handle. And this will complicate the processing of the latter or affect its strength.Therefore, you need to move the template to the most optimal place. Outline the template with a pencil. We obtain the contour of the second handle by turning the template in advance with the narrow part to the side opposite to the direction of the first circled contour. Then, using the square, draw the lines on the sides of the board from the corresponding lines on the wide (main) side of the workpiece and then, turning the template over, circle it on the opposite wide parts of the board.

Step 4. Sawing the board.

Clamp the workpiece in a bench vise. We saw with a hacksaw of a place outside the future handle at 2 or 3 cm intervals, without bringing the saw to a drawn line. The template was circled on two wide sides of the board. And this will contribute to more correct cutting. Also, cuts can be done with an electric jigsaw.

Step 5. The work of the chisel.

Using a chisel and a mallet we remove the unnecessary parts of the workpiece. From the lower grasped side of the chisel handle had to work more carefully. For the convenience of wood processing, the workpiece was cut into two parts. I got the concave sides of the second handle using a jigsaw, so the manufacturing process accelerated, and the result improved. I made the second handle longer than the first, as there was room on the ends of the board.

Step 6. Initial processing with a file and a plane.

To make the handles comfortable to use, the sharp edges of their girths should be rounded. First you need to do this with a plane (upper part of the girth) and a file. We also treat the concave surfaces of the handles and all remaining ribs with a semicircular file.

Step 7. Grinding.

At the final stage of manufacturing, it remains to grind all the surfaces with a grinding machine and sandpaper. Pens are ready to use.

Conclusion

The result was simple door handles. These are just some of the many existing ones. It is possible, using only an electric jigsaw, to make simpler handles with rounded shapes. The presented handles are suitable for the doors of bathhouses, garages, cellars and other outbuildings, as well as for the covers of various barrels. If necessary, drill holes for screws, screws or nails to avoid splitting the handle. There is another simple version of the handle: to fasten two bars to a thick rail. After such decisions one step will remain before primitivism.