A single sleeping bag is a convenience for single tourists due to its light weight and small dimensions. However, if you are traveling together, a double sleeping bag will be a more convenient option for you.

As insulation, fluff of waterfowl is used, because It has a greasy coating and does not get wet. At the same time, fluff isolates very well from the cold and has a low weight. Recently, an artificial substitute has been popular - it is cheaper, but less durable and has slightly less thermal insulation properties. Among artificial substitutes, synthetic winterizer and capron can be distinguished. The latter is more preferable.

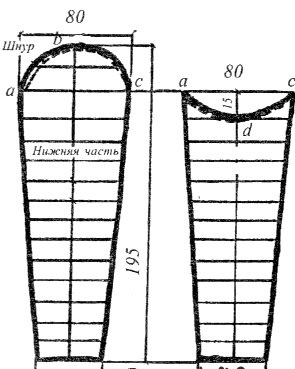

Pattern elements of a single sleeping bag, taking into account the height of a person 185 cm

In the manufacture of the sleeping bag, 2 meters of capron, 2 meters of fabric, 1 meter wide, and 1 kg of down will be used. Also kapron threads.

Considering sharing with a karemat isolating from the soil layer, the bottom of the sleeping bag can be thinner than the top.

It is better to cut the material with a soldering iron on the lining layer in the following sequence:

- external and internal covers;

- a stitch;

- attach a stitch to the covers;

- to sew up compartments for down on one side;

- fill the compartments with down;

- sew up on the other hand;

- sew the details of the sleeping bag;

- stitch a sleeping bag;

- sew in the cord.

There is an option for the combined manufacture of down bags from down and synthetic material in equal proportions. It has the advantages of both materials.

In the manufacture of cotton sleeping bags, the fabric is laid out on a flat surface, a layer of cotton wool is placed on top, covered with a cloth and stitched in several rows in order to prevent the movement of cotton wool inside the bag.

When using synthetic winterizer, they do the same, only the internal and external seams are laid at angles relative to each other.