In addition, the workpieces to be sawed must be pushed along, and for the best quality, they must be pressed against the stop. In some cases, this is dangerous, because you can saw off a piece of your hand.

There are a sufficient number of such stops, today Dania will make one of them.

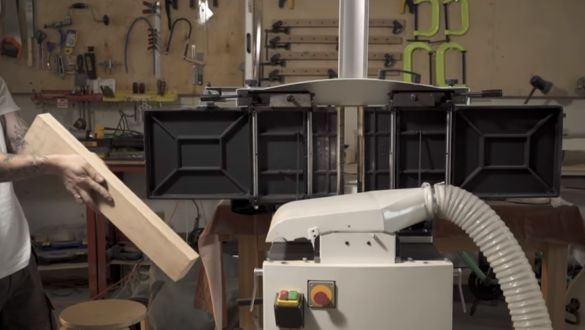

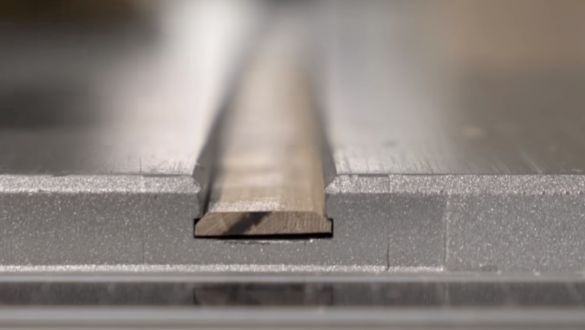

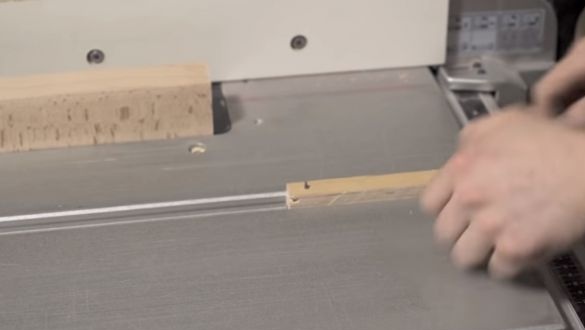

As usual, it all starts with making skids. Somewhere it is necessary to rely, why not in the groove at the sawing.

He drank it so as not to stagger and now uses the last sweet pieces of beech.

Before cutting it, Danya will align the sides, because when you buy a village, they are all crooked.

Or planed, but expensive. And the presence of a chainsaw and jointer will allow you to go into the woods and collect materials from a natural supermarket. Since the beginning of 2019, logging will be officially allowed to collect.

And, in addition to jokes, this is a cool bonus for our country, because in a normal forest you can almost always find a suitable dry tree, lying on the ground. Unlike raw trees, which are best cut in winter, when they are least saturated with moisture, a license is needed for such felling, and fallen dead dead wood can be harvested year-round. Except, perhaps, hot summer days with high humidity.

In general, now in the law, as usual, there are inconsistencies with the instructions of the Rosselkhoznadzor. Even sawing a windfall is classified as theft.

But if you turn on the brain and collect trees that litter the forest, all sorts of bugs and spiders multiply in them.

That, in theory, you will only help the forest. In short, if you include sanity and do not use for personal gain, you can collect with a clear conscience, the main thing is not to run into a forester.

In general, I drove it on a jointer, and then stuffed it several times into a surface gage to make the planes parallel. The result is a smooth bar that can be put on a shelf and admire its evenness.

But Dana does not need him for this.

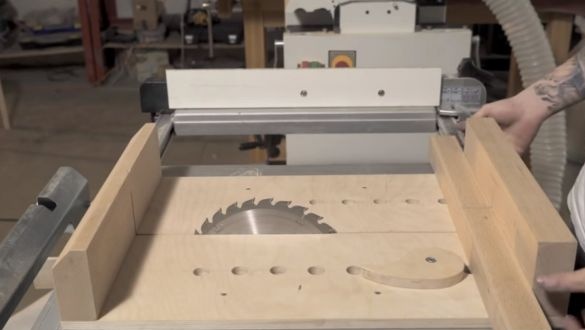

The bar is trimming with a homemade carriage.

Checks the squareness so that everything is clear, and clamps it into the vise of a homemade workbench.

Chamfers, it is especially convenient to chamfer in the vice.

Then it loosens the bar along, two parts are obtained from which an adjustable clamp can be made.

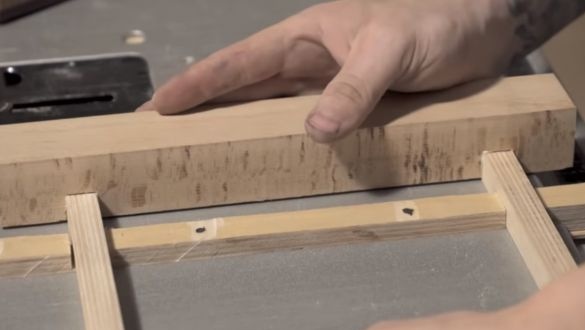

Now the author wants to choose a groove in order to fix the skids better.

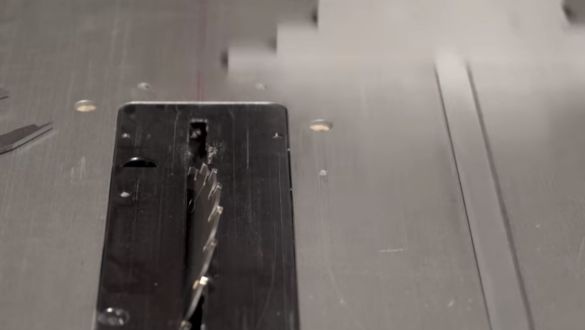

Marks where to remove the material, sets the height of the saw.

And yet, Danya thought so that this emphasis can be slightly shortened, because the main pressure zone is the area of the disk. Therefore, the bar cuts across.

There is a slight gap, but here it does not affect anything.

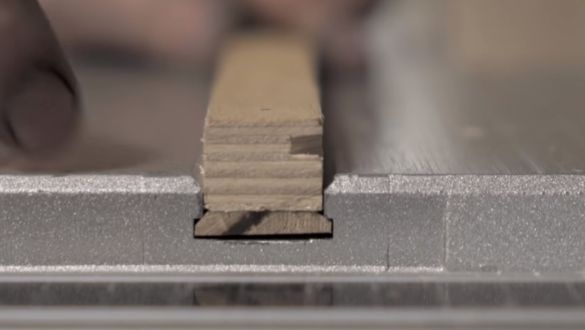

Also, I had to make the lower part for the skid so that in the end she held the t-shaped groove.

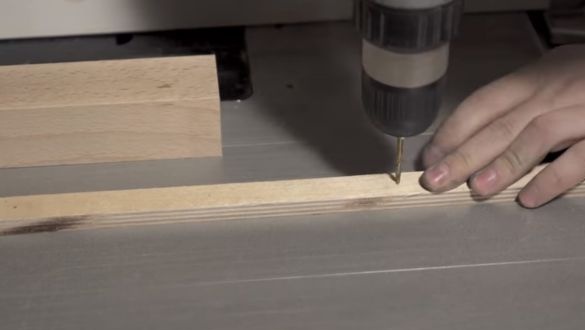

It will be drilled from top to bottom, but not through and through in the lower part, so as not to bore the aluminum groove with a drill.

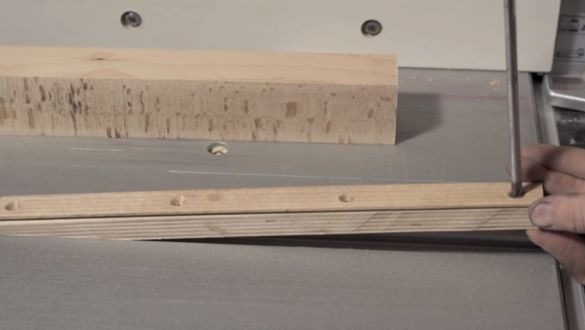

Then he takes out the rail and drills to the end.

And then countersink holes to hide the hats of screws.

It seems to be such a simple, at first glance, thing, but in fact, there is enough fuss with it.

That she glides better, rubs with a blue bolk.

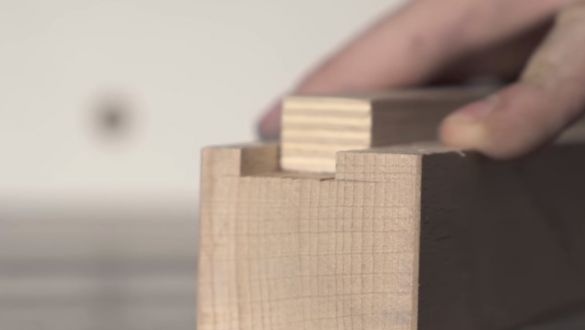

She got into the groove tight enough, but if desired, she can be moved. Exactly what is needed.

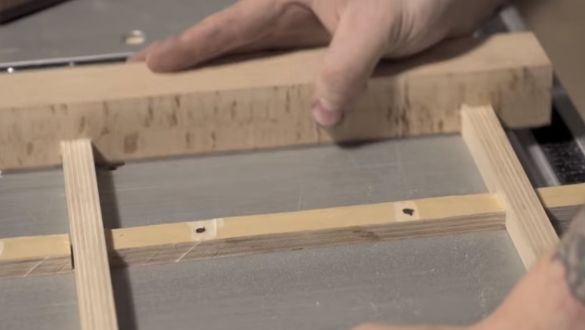

Now marks the places where it is necessary to make a couple more grooves for the transverse pins.

The protruding screws are cut off on a grinding machine. Exposes the necessary height taking into account the carriage, and makes grooves.

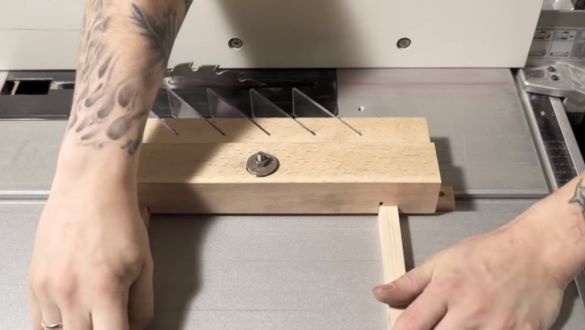

The upper part freely slides on the lower part, now we need to saw the grooves in it.

At the same time, the layer of the moving part of the stop is cut.

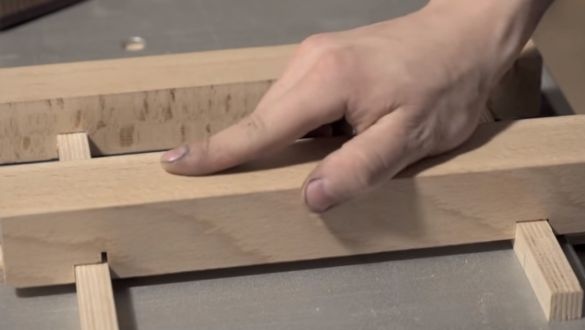

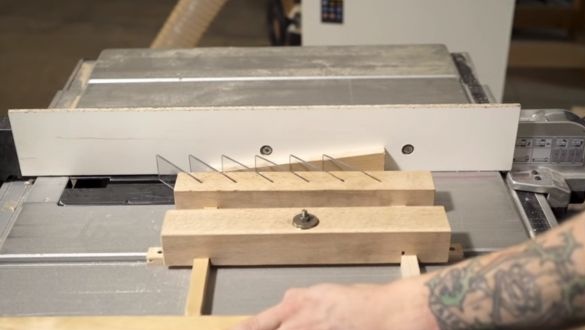

Dania wants to make a structure that will press the material to be sawed, and it can be moved perpendicularly and parallel to the saw blade.

So that you can adjust the force of the clamp and move it to the size of the sawed part.

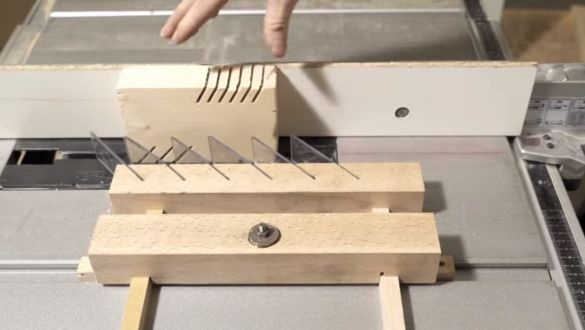

The guides are glued into the movable part, and they should walk freely in the clamping part.

He buys guides and checks accuracy with respect to the second part.

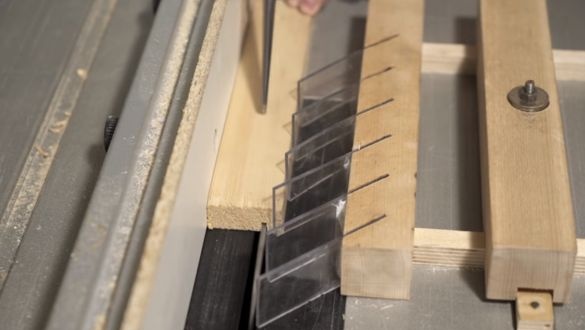

As the pressing petals, Danya decided to saw off a strip of a piled plexiglass.

And you can cut the same rectangles with the help of a carriage and a fixed stop.

You can cut immediately in two strips, getting just two pieces per cut.

Now rotates the saw blade 45 degrees.

And in order not to screw up the carriage, he will use the stock pusher. At the very stop marks out several cuts, in theory 5-6 petals of such rigidity should be enough.

After cleaning any hair that has formed in the place of cuts, you can drive through the thickness gauge, removing half a millimeter.

Now you need to make a clamp that will hold the pressing part.

Drills runners and the upper part, where the bolt will fit perfectly.

It is important to miss, and make a hole in the wrong place.

And then redo it normally, without it in any way. An unnecessary hole will have to be plugged with a dowel.

Drives it inside with glue, and then saws off so that it sticks out flush.

Now the author will need a spring. He will take one of those that remains after Dania gutted the washing machine for useful details.

The author periodically takes these remains, and they find a place in other things, recycling however. This can be done with any mechanism, because there is no dump for ingenuity.

For the spring, you need to drill a landing nest, and in the role of a suitable washer there will be 5 rubles.

It is centered directly in the eagle, and chamfers from two sides.

Now you can collect the emphasis, and for now temporarily insert the petals.

The first test cut was a success, so the petals can be glued.

Dania will use an interesting glue, which is still on the run-in. Because somewhere it fits, but somewhere not really. But what’s cool, he is on a cyanoacrylate basis, and the kit comes with a spray - hardener, which helps a lot. Pours it on a petal, puts it in a cut and puffs with a hardener. That's all, a couple of seconds and he holds tight.

The hardener, so generously poured onto a piece of wood, contains volatile solvents, and after some time it completely evaporates from the surface.

Well, you can test it device.

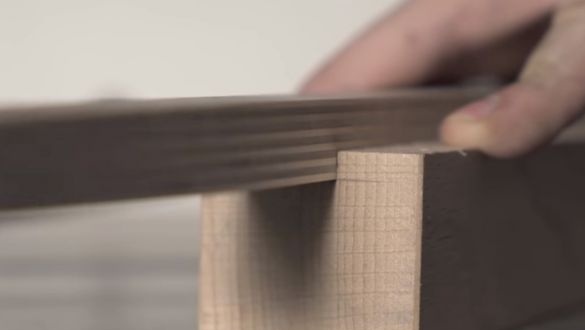

Now you can make such cuts in the right places.

The first thing that comes to the author’s head is the framework for the paintings, and the cuts for the bottom of the drawers.There is also a bunch of art projects where such cuts will need to be done to connect the parts to each other.

Now Dana can be calm for her fingers. At least, using sawing.

When running the bar, you can notice that the emphasis is slightly pushed to the side, thereby he evens out the pressure force.

You can increase it by twisting the nut, which presses the spring.

Thanks to Dana Craster for the great idea and its presentation.

Safe work for you!