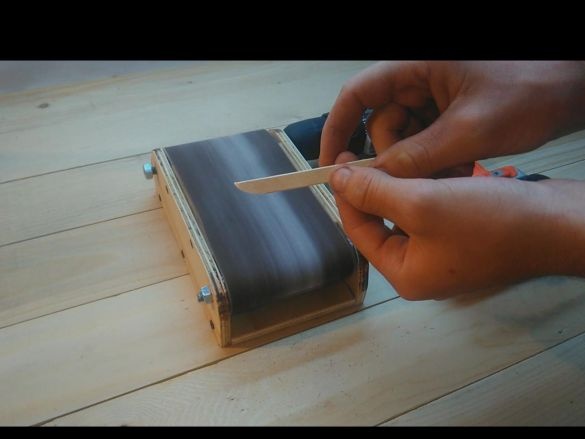

Have a nice time of day, Lord. Many of us like to make various homemade from wood. And over time, you come across such thoughts that you need to purchase a grinder. But not everyone can afford to buy it or make it on their own. But if you have a screwdriver, then you can make yourself a mini grinder, like mine, maybe even better. I do not argue, it is not suitable for large projects of wood, but for the processing of small parts, it can handle it. And for its manufacture, material can be found in each the garage.

Necessary materials:

- plywood

- cylindrical bar

- threaded rod

- washers

- self-tapping screws

- glue

- sandpaper

TEST AND MANUFACTURE CAN BE VIEWED ON VIDEO:

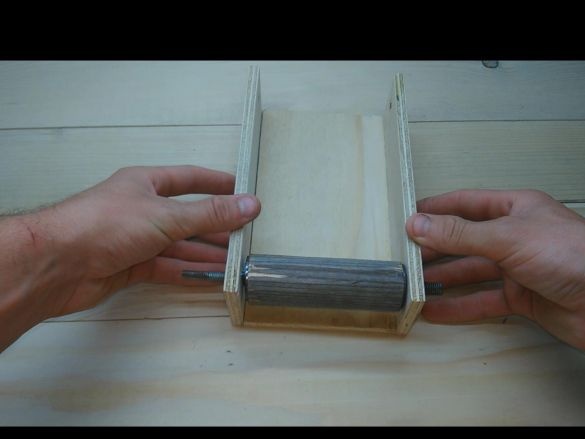

Step 1: Take two cylindrical bars (I sawed off an old shank from a shovel) 100 mm long. And exactly in the center I drilled a through hole with a diameter of 8 mm. Then, finding a suitable threaded stud, cut off two pieces of the desired length from it.

Step 2: We are bored with making one roller spin with the pin and not spin on it. To do this, I took 2 washers of suitable diameter and drilled two holes in them on the sides (see photo). Using nails we fix the washers to a wooden block. And by welding, we weld the stud to the washers. We get a rigid design, now the roller will spin with the pin and will not rotate.

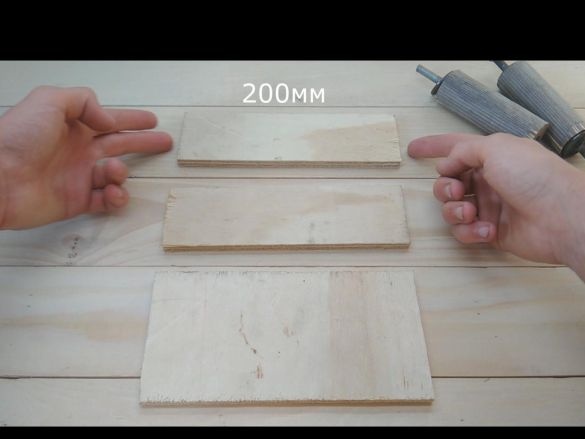

Step 3: We cut out three blanks from plywood: the dimensions of the two upper ones are 200 * 60 mm. lower - 200 * 105 mm. In two identical blanks, we drill holes as shown in the photo.

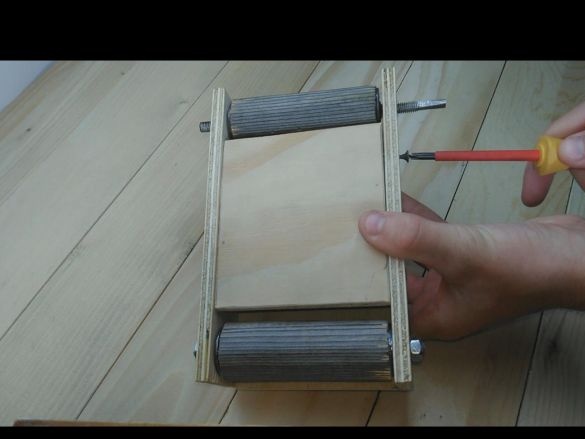

Step 4: Next, we begin the assembly. For this we need glue and screws. Many will say that you need to insert bearings into the holes so that the shaft rotates very well and does not break the holes on the plywood. I don’t argue that you can put it, but in practice, the pin does not break anything and it is good to spin in the holes on the plywood. Another roller simply scrolls on the pin, as the diameter of the hole is slightly larger than the diameter of the pin. From the top we fasten a piece of plywood, it will strengthen the design and sandpaper will not sag.

Step 5: Cut the strip of sandpaper, push it between the rollers and glue its ends together. And presses in the place of gluing with some kind of cargo. Clay, as I do, does a good job of this, so that the ends do not peel off from each other.

The result is a compact grinding machine. Vibrations from him are insignificant, so he will not ride around the table. The button on the screwdriver can be fixed with a plastic screed, it is easily pulled onto the button and can be easily removed. Thank you all for your attention!