Greetings to fans to craft. I present to you a very useful homemadeif you often have to solder something. We will talk about an automatic feeder of solder, in our case, this is a finished solder wire with flux. Now the soldering process will be very simple, for soldering you just need to press the button and now the soldering iron tip already has the right amount of solder. Going homemade is very simple from the available materials.

Let's consider in more detail how to assemble such a homemade product!

Materials and tools used by the author:

Material List:

- ;

- button;

- a piece of board;

- sheet metal;

- reel with solder wire;

- the antenna from the radio (or other suitable tube);

- a nail;

- pieces of tubing made of rubber or the like;

- good glue (quick-drying epoxy or the like);

- self-tapping screw.

Tool list;

- a hacksaw for metal;

- soldering iron;

- drill;

- a screwdriver.

Homemade manufacturing process:

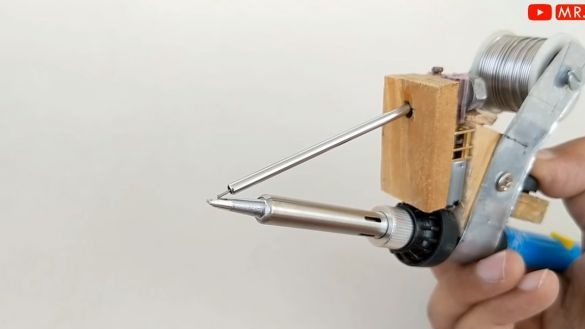

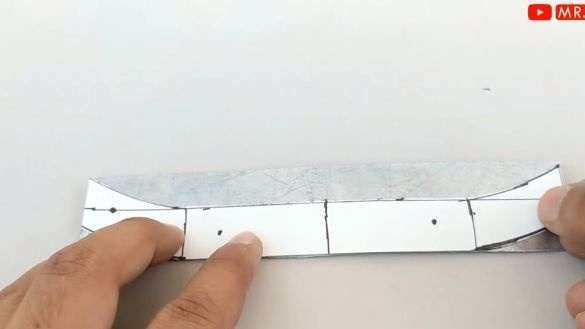

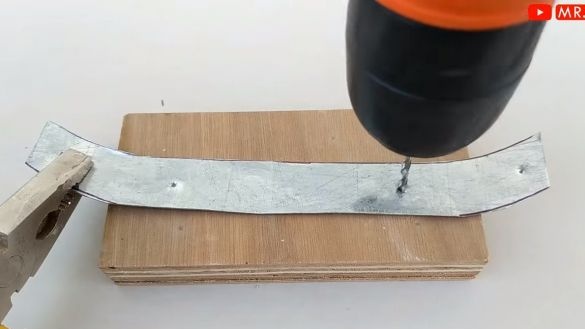

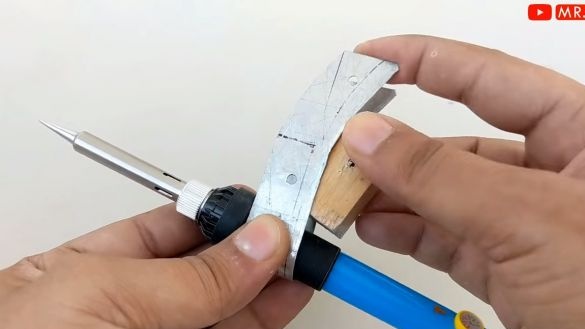

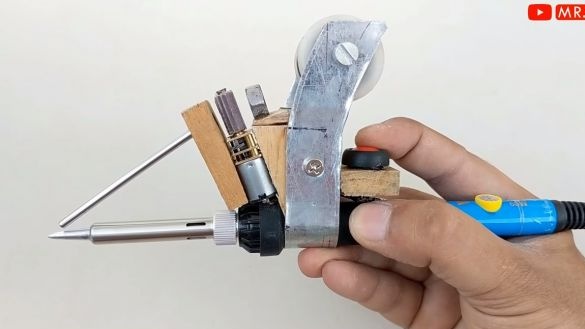

Step one. We make and install the frame

As the frame we will use a piece of board or plywood, as well as sheet metal. We cut the workpiece from metal, as the author in the photo. Next, drill holes and bend the desired shape bracket. He will have to clamp the soldering iron. And now just install the frame on the soldering iron, screw the screw. Half the battle is done, move on.

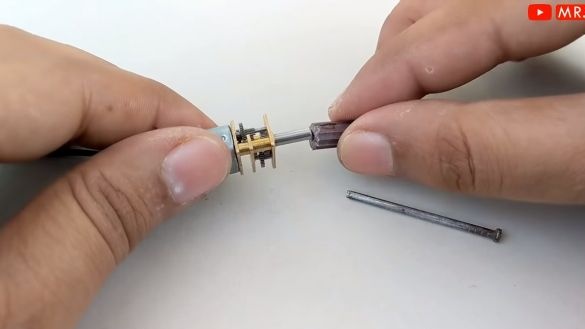

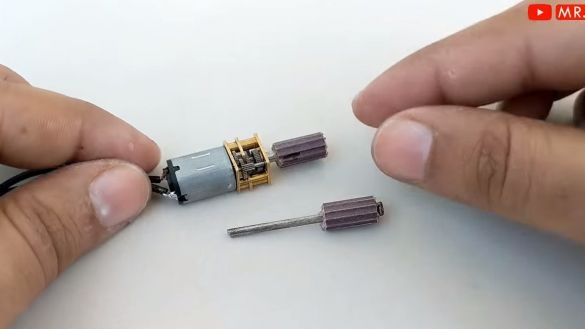

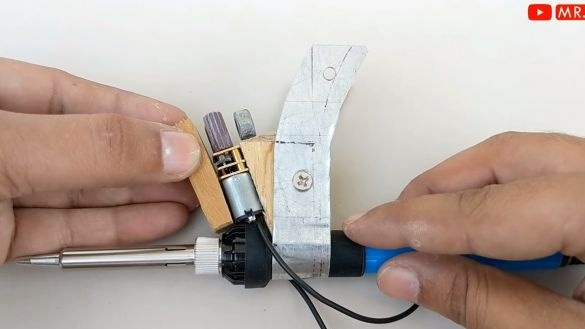

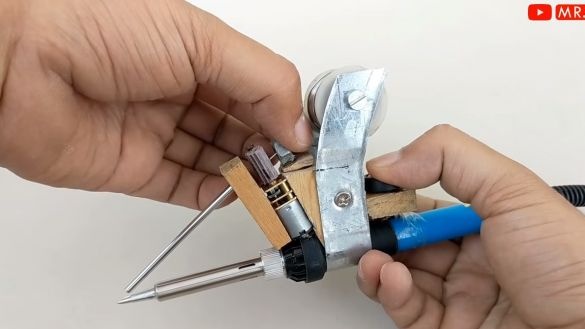

Step Two Install the engine

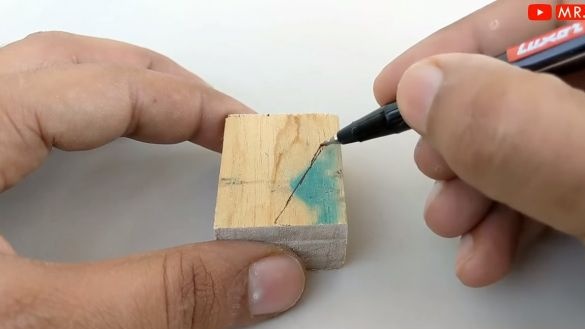

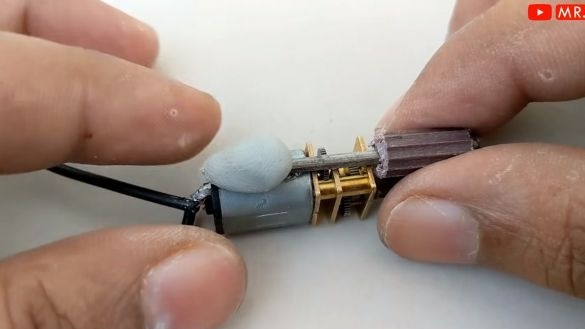

The engine is mounted on the wooden part of the frame; it is glued to good glue. On the engine, you need to assemble the wire feed unit. It consists of a nail that adheres to the engine, as well as two rubber tubes.

To the other side of the motor, we also glue the board and drill a hole in it for the wire, more precisely, for the tube along which this wire will go. Also, on the other hand, glue the nut, which will work like a loop for a wire.

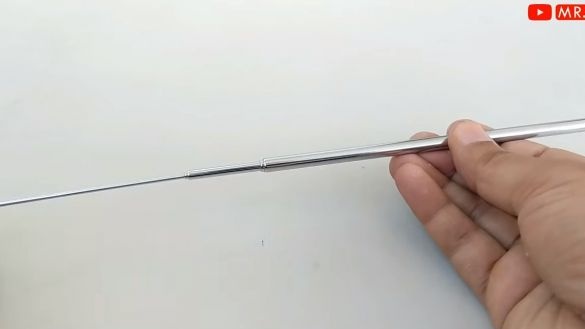

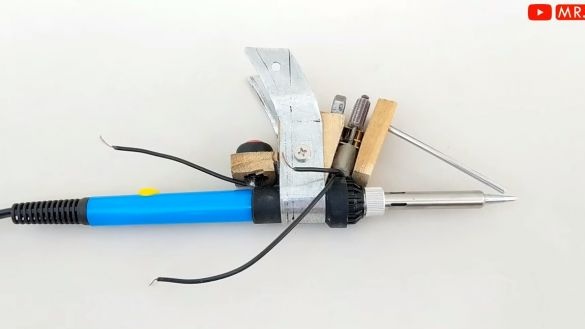

Step Three Further assembly of homemade

Next, install a tube along which the wire will go to the sting. This tube can be glued. And we also need to install the button, fix it with glue in a convenient place to press with your finger. Solder the necessary wires.

In the end, it remains for us to install a coil with solder wire. We fix it with a screw and nut. That's all, we supply power to the motor, we pass the wire and our homemade product is ready for use.

I hope you enjoyed the project and found useful information for yourself. Do not forget to share your best practices and homemade products with us!