Perhaps sometimes the carpentry masters do not have enough miter saw blade depth.

In this article, the author of the channel "Sek Austria" tried to offer a solution to this issue by installing a special set with a chainsaw on the grinder. He also made the basis for it with the possibility of turning the cutting surface at 45 degrees.

Materials and details.

1. The nozzle on the grinder in the form of a chainsaw

2. The grinder (material).

3. Steel strip.

4. Bolts, nuts, small things.

Instruments.

1. The welding machine.

2. Drill or drilling machine.

3. The Bulgarian.

4. Vise.

So, for starters, the author will assemble a set of nozzles for the grinder in the standard version. It is quite simple. Everything is included. Tire, chain, protection, spray can for oil. Even the stars come in two versions M10 and M14. And, of course, the base.

Having assembled the kit, it became clear that when turning 90 degrees, the direction of movement of the chain is not suitable for such an application.

The author decided to remake the grinder and deploy the gearbox in the other direction. To do this, I had to completely disassemble it.

I also had to cut off the extra parts. The grinder from the grinder.

Removes the main part of it.

It turns out that the case will also have to be processed a little with an electric file.

Assembles a gearbox.

Sets the base from the nozzle and decides to get rid of unnecessary for this homemade details.

Now the author needs to make mounting the base of the nozzle to the future base.

Trying on a steel strip.

According to the marking, it slightly cuts with a hacksaw to make the strip easier to bend.

Clamps in a vice and with the help of a hammer sets it to the desired shape.

Perfectly fits the nozzle, it remains to remove unnecessary parts from it.

Cutting off all unnecessary grinder.

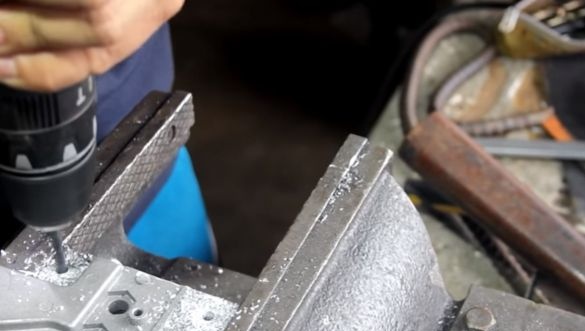

Now you can mark the mounting points and drill holes in the base.

For fastening bolts makes two small rectangular dies. Marks, drills, cuts threads.

Fixes the mount to the base.

It's time to put the tire in its place.

In the mount marks the places for connection with the base.

The base is made of steel strips, welding them together.

With the help of these ears, I saw and will be able to deviate 45 degrees in the plane of the cut.

Welds the ears to the base.

But, having connected the base with the base, it became clear that the tire does not have enough space for an incline of 45.

Cutting off part of the base, everything worked out.

To fix the angle firmly, the author needs to make a lock. Cut an arc slot and get such a workpiece.

Trying it on to the base and welding. Everything is rigidly fixed.

For convenience of operation adjusts the handle.

It also moves the pen and oiler to the other side.

All is ready!

It's time to start the test.

It starts with a 1.5 inch board, the cut is quite smooth.

Next is 3 inches of mahogany. Everything is fine too, even at an angle.

But the tool was not intended for such a trifle. 8X8 inches!

In general, the power of this saw is enough to even even cut such a log.

Thanks to the author for the interesting tool!

Good ideas to all!