And for them sometimes the simplest things are required. It is in this article that Andrei Yarmolkevich, the author of the channel of the same name, will show the process of creating convenient, non-sliding “lamb” or handles for clamping, adjusting your tools.

An experienced craftsman knows that during the assembly of various devices, either screws or nuts with convenient handles that can be loosened and twisted without a tool are often needed. Here are some, for example:

Andrei Yarmolkevich in this article will tell us how he mastered a very simple technology for the production of such pieces using a drilling machine.

Using a hole saw, he first makes the circles themselves. For his product, the author selects oak planks.

In the course of work, Andrei notes that he does not have a very good set of similar circular saws (Bosch firms), which is rather a cheap option. But at the same time, he notes, it is more convenient to use them than crowns, since it is much easier to get round ones out of them.

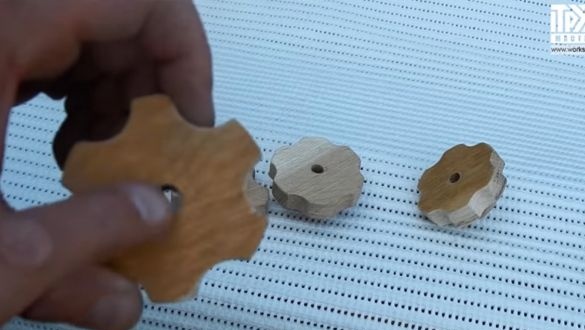

So the author made these round and round big and small round ones.

Now Andrei will put into action this simple device with a hole of 8 mm. The guide drill in the circular saw is also 8 millimeters in diameter. A bolt is inserted into the plank, the nut is tightened and locked.

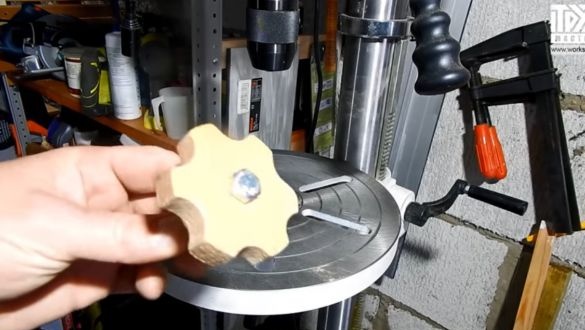

The machine at the author is Jetovsky, 13FM. It has such a round table that can rotate. It is fixed from the bottom. Thanks to this, it becomes possible to rotate and lock it in the desired position.

The next step, the author secures this device so that the axis of the bolt coincides with the axis of the hole. For this purpose, he will use a cartridge. Then he aligns the table so that the axis of the hole coincides with the axis of the cartridge.

Then it’s over the cartridge and aligns this device.

Using a Forstner drill, he set the table so that the axis of the hole and the chuck match.

Further, I fixed a thin drill in the cartridge and the device will align it.

From the bottom, Andrei will fix them with screws and washers. Aligned, secured.Then he removes the small drill and puts the Forstner drill in its place. The table, as mentioned above, can be moved to the right and left.

The author exposes it so that the drill goes a little on the rounds, after which the table fixes.

There is no rotation scale on this table, but there are six slots that the author will focus on.

So, he puts out a table, having previously fixed it, drills it. Then it releases the fixation again, turns again and drills again.

As a result, Andrey gets just such a knob twist, and quite quickly. It remains only to modify it a little bit with sandpaper.

Then he polished the handles slightly and glued such small round circles to them, then clamped them with bolts and nuts and washers.

These are the twist pens. Now, according to Andrei, depending on the need, you can either embed a bolt head here - then you will get a screw, or insert a nut.

Here the hole is 8 millimeters, if you need a smaller diameter, you can hammer the dowel on the glue and drill holes of the desired diameter. Everything is pretty fast. And all you need is a drill machine and nozzles.

That's all, thanks to Andrei Yarmolkevich for an interesting idea!

All good homemade.