This article will be of interest to the owners of a large garden. In it, the author of the channel “1000 DIY AND TIPS” will show how he made a powerful garden juicer.

If you need to squeeze juice from a pair of buckets of apples, just buy a household juicer.

But, with large volumes of initial production - you will not regret it if you do something similar for yourself.

The author will collect and experience this garden miracle.

A link to the drawings, a description of the characteristics and advantages - at the end of the article.

The frame for the press was cooked by the father of the author.

He has such an idea - a tank for crushed fruits will stand below, he wants to fix the crusher above.

And here the jack will hang.

But the author does not like the position of the engine. It is also not clear how to tighten the belt.

These are the pensioner's nice welds.

The author will improve this design, cut the excess and polish it.

The engine will be attached to this plate.

Hinges made of pipes, all this will be attached to the frame like this.

Below, for stability, I welded two pieces of a square pipe.

The finish line is still far away, but it will be something like this.

He welded the hinges, hung the engine and made a support under the crusher tank and out of a square pipe.

Under the belt tensioner adapted the old steering rod.

Everything turned out very simple, cheap and compact. Both shafts are now located at the bottom - so much safer and prettier.

380 volt engine. Later, it may redo it to 220.

And the engine from the machines connects with a short piece of cable.

The thinnest wire, earthen, cuts off.

The rest connects to the engine.

At the other end, the earth wire also cuts off, the rest connects to the machine.

On this side of the machine connects the cable going to the outlet.

This green-yellow earthy wire. Increases it and fastens to the engine case.

Here is a visor welded over the crusher tray. It will shorten it later.

I disassembled the entire structure and prepared it for painting.

I cleaned the rust with a grinder with a cleaning disk and degreased it.

Steel parts are coated with acid primer.

Then applies silver metallic.

He painted everything, even a stainless steel crusher tank.

After painting, applied varnish, which is dry until morning.

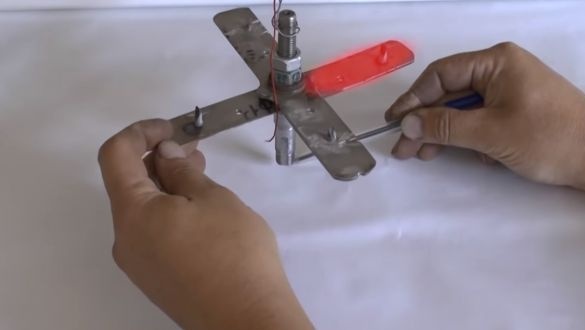

The author’s father made knives from stainless steel, there were great doubts about them.

Many people make knives from circular saws because they do not need to be balanced.

But circular saws can rust, especially in an acidic environment.

He adapted the shaft and pulley from an industrial sewing machine.

The author will try to balance the knives. For balancing, I fixed the thread in the center of the shaft, twisted it.

Then he looked in which direction the shaft deviates stronger during rotation. He made a heavier knife a little narrower.

The lower knife of the crusher rotates a couple of millimeters from the bottom. The second - 7 millimeters higher.

At the beginning he collects a crusher, everything is simple here.

Installs the shaft, key, pulley, lock washer and nut.

The nut is fixed with a washer, bending its edges.

Proceeds to assembly, puts the plate in place.

It is possible without this nut, but since it is, it tightens it.

Now installs the motor.

The tensioner is screwed to the end.

And screw it to the plate.

He puts the crusher tank in its place, it is fastened on both sides by 10 nuts.

He puts on a belt and pulls it a little.

Screws the machine, drilled holes in advance and cut the thread.

The cable is neatly laid and secured with ties on the frame.

Checks the crusher, everything works fine, quiet enough.

A tap is screwed to the tank, juice will flow only when needed.

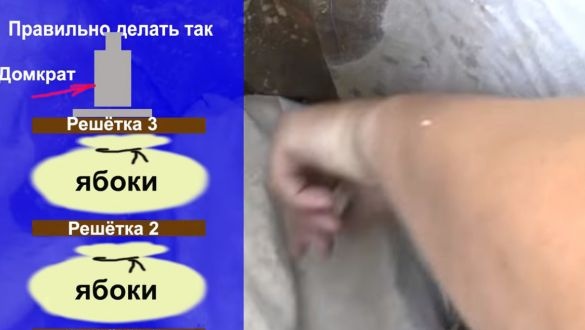

At the bottom puts an oak lattice.

Now inserts oak chain mail. Juice will flow along the walls between these bars.

It is necessary to make an intermediate lattice. Although the jack is 5 tons, even it without intermediate grilles will not be able to squeeze the juice well. If the grilles are installed every 15-20 centimeters, then the cake from the apples will be almost dry.

And finally, the final touch. Without protection, apples will fly out of the crusher. Many make a crusher three times higher. The author decided to adapt the lid from the old juice maker, which will be attached to the grinder using ordinary rubber bands and hooks.

In addition, it will serve as a funnel.

Now everything is ready, the tray protection had to be shortened, it interfered with the jack.

At the beginning, a linen bag was used as a filter. Apples on the press allowed only those that fell.

The rot was trimmed and washed. About 40 liters of crushed apples should enter the tank. Let's see how long it can be filled.

A bucket of apples is crushed in 30 seconds.

Half of the tank is already crushed. It took a couple of minutes to install an intermediate grille.

Ten minutes later, the tank was full. They pulled up the bag, laid the lid, block, and hung the jack.

Opens a tap and the juice has already gone.

The stem of the jack is completely out, puts another block, then another one.

Despite the fact that he could not stand it and the bag burst, two and a half buckets of juice were collected.

For several visits, the entire work cycle was debugged. And the author confidently says that this juicer justifies itself by 300%.

Advantages and disadvantages.

The linen bag was replaced with a polypropylene bag. Sugar bags proved to be excellent. A linen bag was hardly pulled out of chain mail. Polypropylene come out with a whistle, in addition, they are stronger and filter the juice well.

The cake is almost dry and shakes out easily. It is enough to rinse and apply again.

Round tank, tank walls protect the juice from dust, debris and wasps. You can do without a faucet, but not a drop of juice will be lost with it.

Initially, the author was inclined to a square tank, but such a chain mail from oak bars will not stand in a square tank. Again, when there are fewer seams and corners, it’s easier to wash.

A jack would probably be enough for 3 tons. It would be a little easier. The crusher pleasantly surprised, at three thousand revolutions per minute it turns out real mashed potatoes.

Processing speed is also high - a bucket of apples turns into mashed potatoes in just 30 seconds. Less contact with air - less oxidation.

If desired, additional spikes can be screwed in.

Threaded holes were made with a margin, but it seems to the author that it will no longer be better.

The disadvantages include the neck of the funnel.When there are few apples in the crusher, drops of mashed potatoes fly from the throat, apples do not fly out.

This problem can be solved by making a spring or rotary damper. Or increase the height of the crusher by 20 cm. But, having made the crusher higher, you will have to raise the bucket with apples higher.

A slot has been specially left in the visor above the tray; the damper is not inserted into it. After installing the damper, the crusher will be able to grind corn, wheat, and so on.

The undisputed advantage is its performance. To get a household juice extractor, 50 liters of juice would have to spend a whole day. In addition, apples for her need to be cut, they do not fit in completely.

This 50L juice harvester makes effortlessly in 30-40 minutes. Complete assembly and disassembly takes no more than 10 minutes. The frame can winter the garden, the rest of the details can be stored in a large tank.

67 dollars were spent on the manufacture of a press crusher. Some materials will cost less, some more expensive.

It is important to understand that it can pay for itself in one season. With it, you can travel to cottages and provide services at home. And over the years this press will not become cheaper.

In conclusion, a few words on the characteristics. Height exactly meter, width 57X45cm, total weight 68kg.

Link to frame and crusher drawings.

Thanks to the author for a useful idea, it is clearly useful to summer residents and small farms!

Good ideas to all!