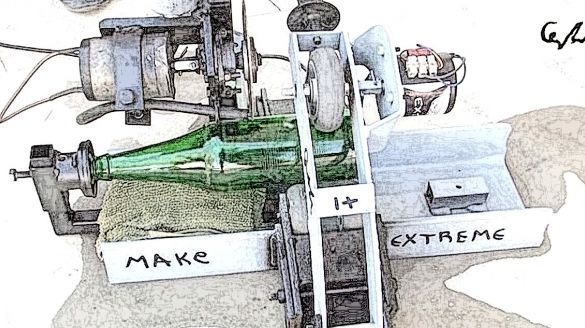

Interesting was raised topic. The author of the "Make it Extreme" channel automated this device a bit. This article will focus on the bottle cutter. A very useful thing, especially for design lovers.

Instruments.

1. Bulgarian

2. Lathe

3. Welding machine

4. Miter Saw

5. Plasma cutter

6. Screwdriver

7. Electric scissors

8. A hammer, rulers, corner, pencil, taps, lerka, etc.

Materials

1. Furniture wheels

2. Sheet steel strip

3. Steel bar

4. Channel, profile pipe

5. Plastic bottle and tube

6. Motors

7. Reducer from the grinder.

The author begins by excavating metal scraps.

Having found a suitable channel, marks it up and begins to make the base of the machine.

A miter saw cuts through a groove.

Using a plasma cutter, makes grooves for the movable part.

Then knocks it out with a hammer.

A miter saw cuts blanks from a steel strip, these will be wheel holders.

Trying on furniture wheels, marks the places for drilling.

Drills workpieces.

Using a tap, cuts the thread.

Screws in a bolt, drills a second hole.

These are the axis obtained.

Welds the cross member.

Disassembles the wheels and sets them on the axle.

This is how the supports for the bottle will be folded.

Drills a hole in the cross member and cuts the thread.

Lerka cuts threads on a steel bar.

Sets the lamb that controls the height of the wheels.

Trying on an engine that will rotate the bottle.

Makes a clamping device.

Disassembles the grinder, the author needs a gearbox flange.

Tries on the flange and assembles the cutting part of the machine.

Sets the handle of the grinder.

Assembles a pressure bracket, bottle neck holder.

Welds a profile pipe to the channel, the holder will be fixed in it.

This is how the neck will be fixed.

From a plastic bottle and tube makes a lubricating disc dropper.

Everything is ready, you can test the machine!

These are the results obtained.

Thanks to the author for an interesting idea and its implementation!

Have a good tool!