Many of us turned out to be the owners of the finished power supplies left over from routers, external hard drives, laptops, monitors, and so on. Typically, the output voltage ranges from 12v to 22v. I hope this article will give you an idea how to use such a power supply without disassembling it and without interfering with its factory assembly.

To build an amateur set-top box with continuously adjustable output voltage, we need:

- a ready-made module on the lm2596 chip;

- mounting box;

- two nests with an internal diameter of 5.2 mm;

- potentiometer 10 kOhm;

- two permanent resistors 22 kOhm each;

- panel ampere voltmeter DSN-VC288.

The article will consist of several finished parts, each of which will describe in detail the steps, features and pitfalls of the components used.

Chip DC-DC converter lm2596

The lm2596 microcircuit, on which the module is implemented, is good in that it has overheating protection and short circuit protection, but has several features.

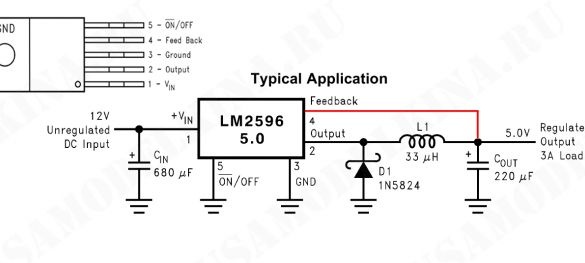

Look at a typical version of its inclusion, in this case, a microcircuit of the editorial output fixed voltage +5 volts, but for the essence it does not matter:

Maintaining a stable voltage level is ensured by connecting the feedback output of the fourth (Feed Back) leg of the microcircuit connected directly to the output of the stabilized voltage.

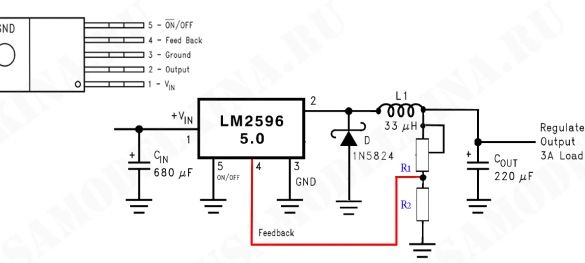

In the particular module under consideration, the version of the chip with a variable output voltage is applied, but the principle of regulating the output voltage is the same:

To the output of the module, a resistive divider R1-R2 is connected with the upper trimmer resistor R1 turned on, introducing the resistance of which, the output voltage of the microcircuit can be changed.

In this module, R1 = 10 kOhm R2 = 0.3 kOhm. The bad thing is that the adjustment is not smooth and is carried out only on the last 5-6 turns of the tuning resistor.

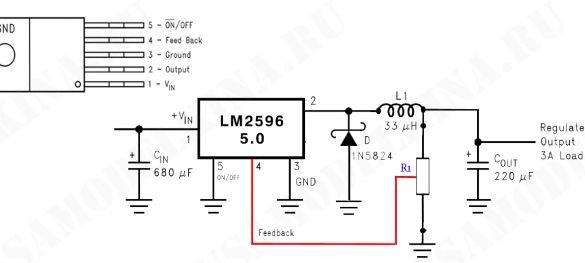

To implement a smooth adjustment of the output voltage, the ham eliminates the resistor R2, and the trimming resistor R1 is changed to alternating.

The scheme goes like this:

And right here, a serious problem arises. The fact is, during the operation of a variable resistor, sooner or later, the contact (its contact with the resistive horseshoe) of the middle output is broken and the output 4 (Feed Back) of the microcircuit is (even for a millisecond) in the air. This leads to an instant failure of the chip.

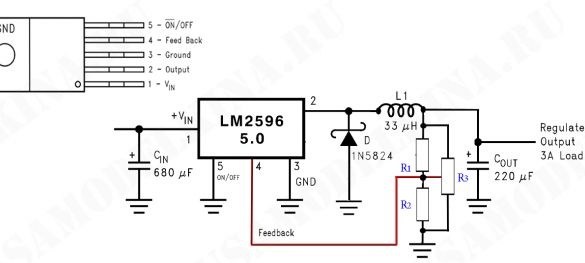

The situation is also bad when conductors are used to connect a variable resistor - the resistor turns out to be remote - this can also contribute to the loss of contact. Therefore, the standard resistive divider R1 and R2 should be unsoldered, and instead of it, soldered two constants directly on the board - this solves the problem of loss of contact with a variable resistor in any case. The variable resistor itself should be soldered to the soldered terminals.

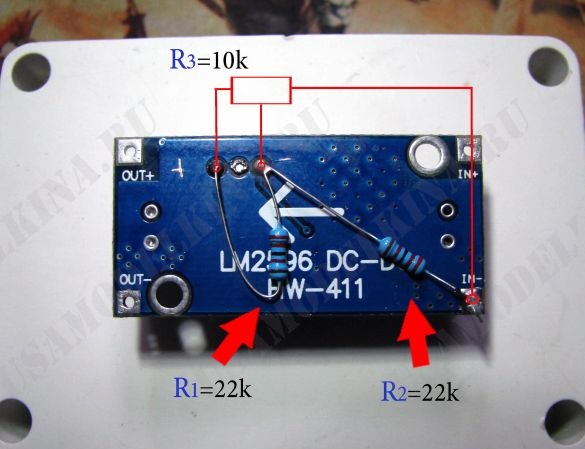

In the diagram, R1 = 22 kOm and R2 = 22 kOm, and R3 = 10kOm.

On a real diagram. R2 was a resistance corresponding to its marking, but R1 surprised me, although it actually has a 10k mark, its nominal resistance turned out to be 2k. =)

Remove R2 and place a drop of solder in its place. Remove the resistor R1 and turn the board over to the reverse side:

Solder two new R1 and R2 resistors guided by a photo. As you can see, the future conductors of the variable resistor R3 will be connected to three points of the divider.

That's it, put the module aside.

Next in line is a panel ammeter.

DSN-VC288.

The DSN-VC288 ampervolmeter is not suitable for assembling a laboratory power supply, since the minimum current that can be measured with it is 10ma.

But the ampervoltmeter is great for assembling an amateur design, and therefore, I will use it.

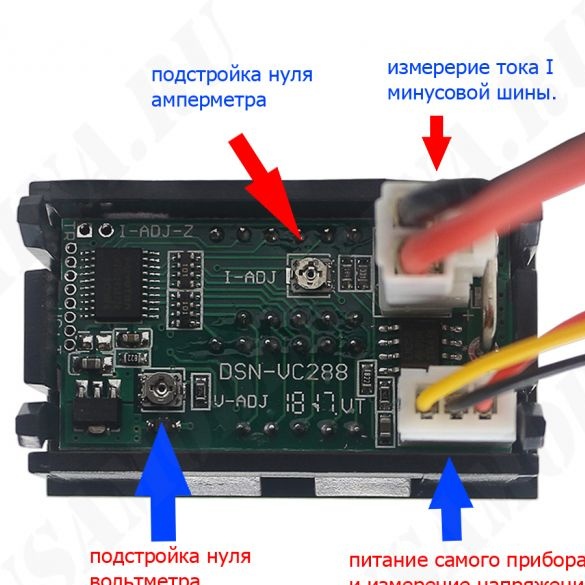

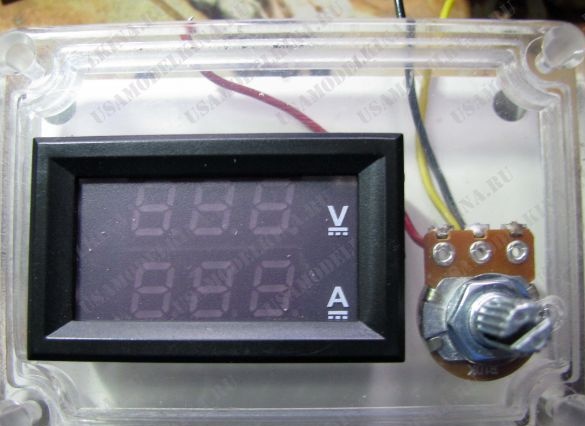

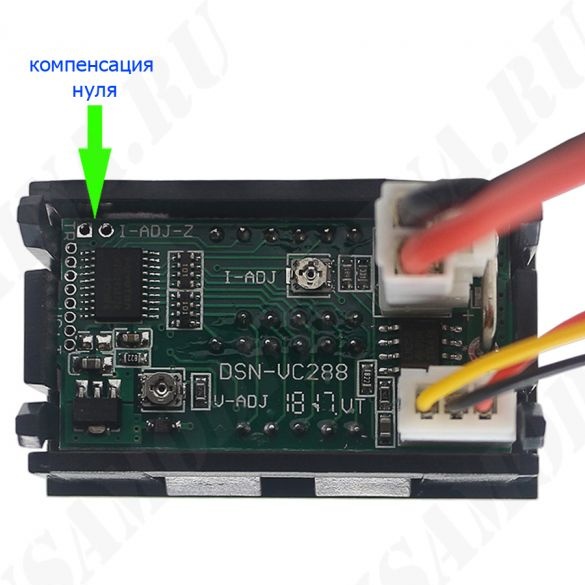

The view from the back is as follows:

Pay attention to the location of the connectors and the available adjusting elements, and especially to the height of the current measurement connector:

Because, selected by me for this homemade Since the case does not have sufficient height, I had to bite the metal pins of the current connector of the DSN-VC288, and the thick wires that came with it - to solder the pins directly. Before soldering, make a loop at the ends of the wires, and by soldering each on each pin, solder - for reliability:

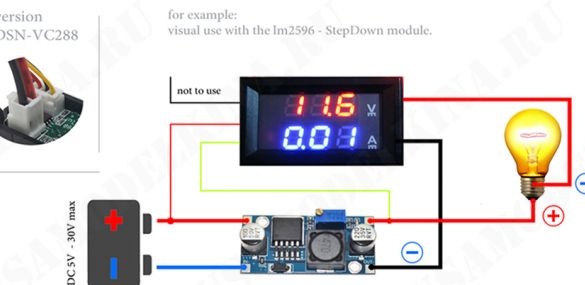

Visual layout DSN-VC288 and lm2596 connections

Left side of DSN-VC288:

- the black thin wire does not connect to anything, isolate its end;

- yellow thin connect to the positive output of the lm2596 module - LOAD “PLUS”;

- red thin connect to the positive input of the lm2596 module.

Right side of the DSN-VC288:

- black thick connect to the negative output of the lm2596 module;

- red thick will be LOAD "MINUS"

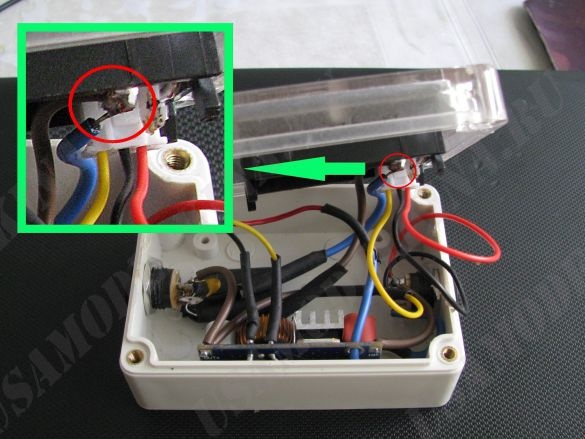

Final assembly.

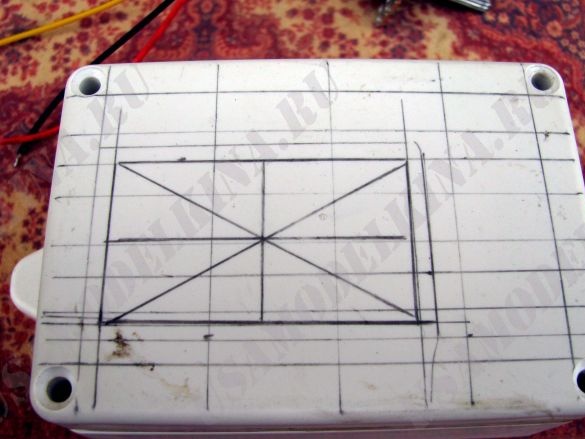

I used the mounting box with dimensions of 85 x 58 x 33 mm .:

By marking with a pencil and a dremel disc, I cut out the window for the DSN-VC288 to fit the inside of the instrument. At the same time, at first I sawed the diagonals, and then sawed off individual sectors along the perimeter of the marked rectangle. We’ll have to work with a flat file, gradually adjusting the window under the inner side of the DSN-VC288:

In these photos, the cover is not transparent. I decided to use transparent later, but it doesn’t matter except transparency, they are absolutely identical.

Also, outline the hole for the threaded collar of the variable resistor:

Please note that the mounting ears of the base half of the box are cut off. And on the chip itself, it makes sense to stick a small radiator. At my fingertips were ready, but it’s not difficult to cut a similar one from a radiator, for example, an old video card. I sawed a similar one for installing a laptop chip on a PCH, nothing complicated =)

Mounting ears would interfere with the installation of these 5.2mm sockets:

In the end, you should get exactly this:

At the same time, on the left is the input jack, on the right is the output:

Check.

Apply power to the set-top box and look at the display. Depending on the position of the axis of the variable resistor of the volt, the device may show different, but the current should be at zeros. If this is not the case, then the instrument will have to be calibrated. Although, I read many times that the factory has already done this, and nothing will have to be done from us, but still.

But first, pay attention to the upper left corner of the DSN-VC288 board, two metallized holes are designed to set the device to zero.

So, if without load the device shows a certain current, then:

- turn off the console;

- securely close these two contacts with tweezers;

- turn on the prefix;

- remove the tweezers;

- disconnect our set-top box from the power supply, and reconnect it.

Test to the load.

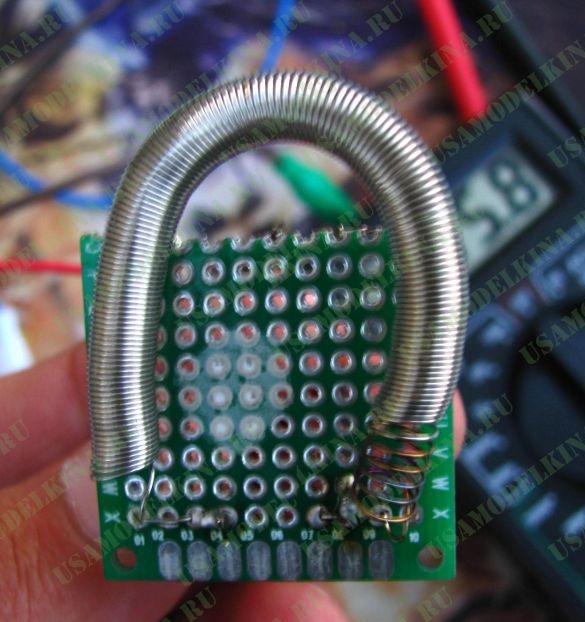

I do not have a powerful resistor, but there was a piece of a nichrome spiral:

In the cold state, the resistance was about 15 ohms, in the hot, about 17 ohms.

In the video, you can watch the tests of the resulting set-top box just for such a load, I compared the current with the standard device. The power supply was taken at 12 volts from a long-gone laptop. The video also shows the adjustable voltage range at the output of the console.

Total.

- the prefix is not afraid of a short circuit;

- not afraid of overheating;

- not afraid of open circuits of the control resistor, when it breaks, the voltage automatically drops to a safe level below one and a half volts;

- the prefix is just as easy to withstand if the input and output are reversed when connected - this happened;

- there is an application to any external power supply from 7 volts and up to 30 volts maximum.

Video: