Tools and machinesused by the author.

- Lathe

- Drilling machine

- Welding machine

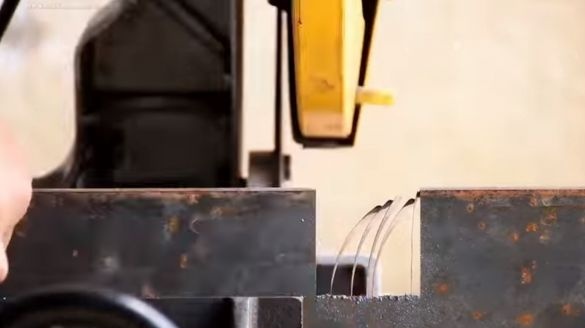

- Bulgarian, screwdriver, miter saw

- Small tools - drills, hammer, lerka, taps, etc.

- Spray paint.

Materials

- Steel plate 120 wide and 16 mm thick

- Steel channel, round timber

- Sheet steel

- The steel pipe.

So, the author has two large metal plates. In the manufacture of heavy duty vices, the master decided to use these plates, having previously altered their shape somewhat. Each plate has a width of 120 cm and a thickness of 16 mm. Cuts the desired size, makes a rectangular selection in the plate with a miter saw.

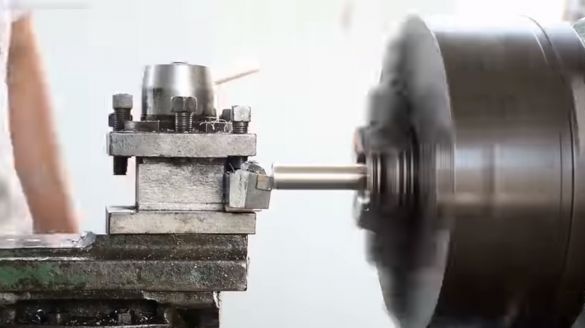

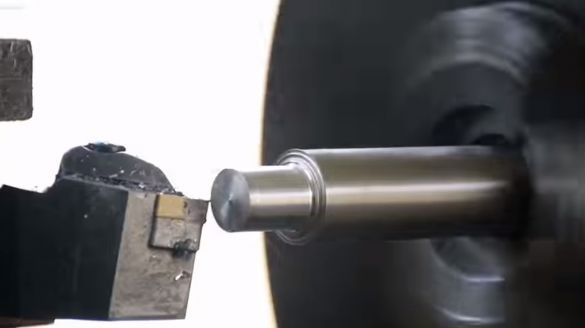

Then, on a lathe, it processes a steel round log, making a lead screw.

The screw cuts the thread.

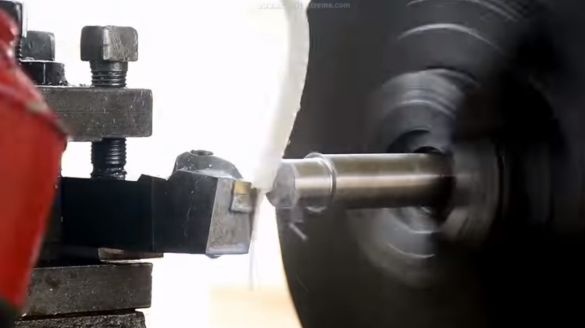

And the spindle will hold the extended nut.

As a vise base plate, the author used a metal circle 10 mm thick and 30 cm in diameter.

Welds the nut to the base plate.

Makes a reciprocal mount of the shaft, when turning, moving from a small diameter, verified to a large one. It cuts the internal thread.

Presses a bearing into it.

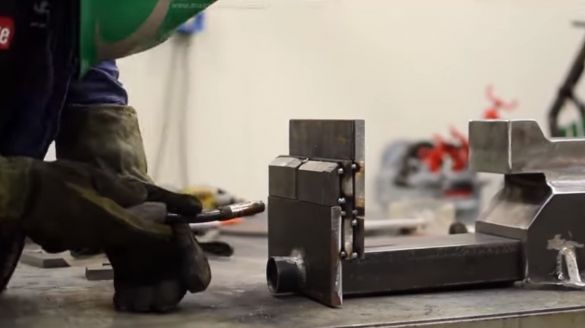

Then, by welding, he joined together several pieces of a metal plate and channel, formed a solid base of future vices with a rectangular hole in the center, in which the moving elements of the vise should move.

Continues to form the base, for reference, trying on the old anvil.

Having formed the sides, reinforces the design with a set of steel plates.

Boil all the seams very carefully.

Cleans seams and edges.

Installs the movable part in the base.

With the help of small metal corners, reinforces the structure again, welding them between the sides and the base plate.

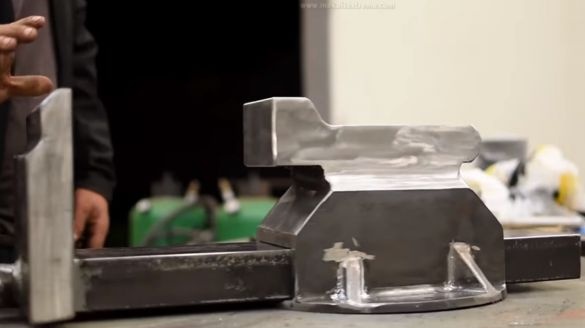

Then it forms a fixed sponge of a vice. In its front, protruding part, the author leaves a groove into which interchangeable linings of various shapes can be inserted.Thus, the master has several options for operating the device, depending on the purpose for which he is going to use this tool - for forging, chopping, riveting or bending workpieces, and also depending on the form of materials with which the master has to work.

Also, on the movable part of the vise, the author created another holder (sponge) located exactly at the same height and width as the fixed jaw of the vise. As a result, when the movable sponge closes with the fixed one, the object located between the jaws is firmly fixed between them. The movable part of the tool is moved inside the cavity located in the center of the fixed part of the vise, it is shifted using a screw. The advantage of using this clamping method is that it gives a very small percentage of rejects due to the greater clamping force of the workpieces. This allows you to process them with millimeter accuracy.

Continues to expand the holder of the movable jaw, adding more and more plates.

After stripping, the vise has already acquired the outlines familiar to all.

Welds one more part of a motionless emphasis.

Starts to make removable red-hot sponges. The mount will be in the form of a "dovetail"

Sets sponges.

Drills a small hole for the fixing screw, taps the thread. Screws in a bolt.

Jammed shaft with adapter sleeve.

He tries on a handle from a round log, cuts it on a turning thread for the lock on one side.

Then, turning the workpiece over, repeats on the other, winds the latch. Inserts the handle into the coupling, twists the second clamp.

Having prepared a hole in the fixed part, makes a mount for lifting the vise.

Raises the vise with a winch and weighs out. It turned out 92.7 Kg.

It paints the finished product with spray paint.

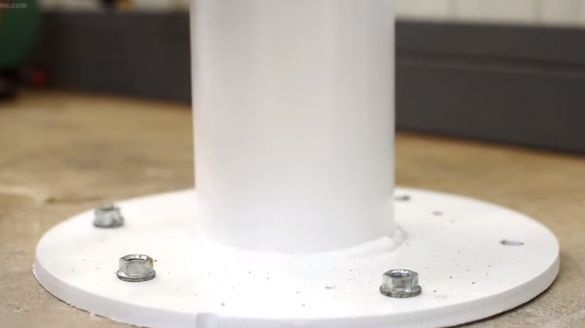

While the paint is drying, it makes a rack from steel circles and pipes.

Fastens it to the floor with anchors.

Assembles the entire structure.

The last step hardens the removable jaws. The temperature of the heated muffle furnace is 752 degrees.

After heating the sponges, it cools them in oil.

Sets everything in its place, clamps the lips with clamps.

Everything is ready, the handle spins very well. Clamps the channel in a vise.

That's how reliably it turned out.

The threaded axis (screw clamp), which the author made on a lathe, was made of stainless steel to avoid rust and rapid wear of this functional part of the vice. Thus, when the screw clamp rotates to the right, the movable part of the vise moves closer to their fixed part and vice versa, when rotating to the left, both parts diverge.

Ultimately, in order to achieve sufficient clamping force, the author made a large lever, which significantly increased the power of the lead screw. At the same time, the force of fixation of objects enclosed in a vice increased accordingly. The total weight of the vice is 92.7 kg.

Thanks to the author for the excellent performance of a reliable tool!

Good luck to all!