The site provides several instructions on how to make a whistle. There are difficult to execute, there is easier. Making the whistle presented in this article requires a lathe, but the result is worth it. So, to make the whistle, the master used the following

Tools and materials:

- Brass bar;

-Solder;

-Wooden bar;

-Lathe;

-Cone drill;

- Files;

-Burner;

-Sandpaper;

-Polishing disc;

-Vise;

Step One: Theory

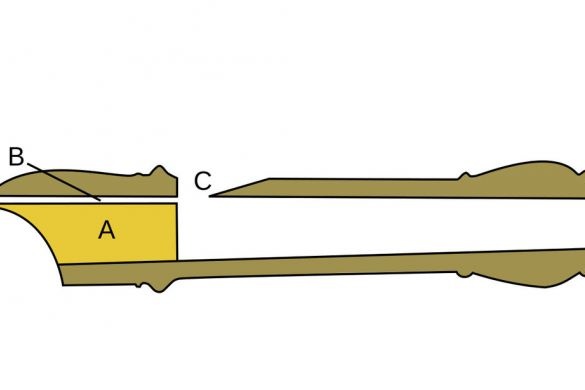

In the first step, the Master reminds us how the whistle works.

Air, under pressure, passing through channel B and reaching resonator C makes a sound. The greater the pressure and flow rate, the lower the tone, and vice versa.

Step Two: Workpiece Processing

Clamps a brass blank in a lathe chuck. A hole is drilled in the center of the workpiece.

Step Three: Insert

Turns a brass insert along the diameter of the billet hole.

Now the insert (sleeve) needs to be cut at a certain angle. To do this, the master drills a hole in a wooden block at an angle of 25 degrees. Inserts a sleeve into the hole. Sews the sleeve.

Drills another hole in the bar. Inserts a sleeve into it. Cutting off part of the sleeve.

This is the shape of the insert.

Step Four: Resonator

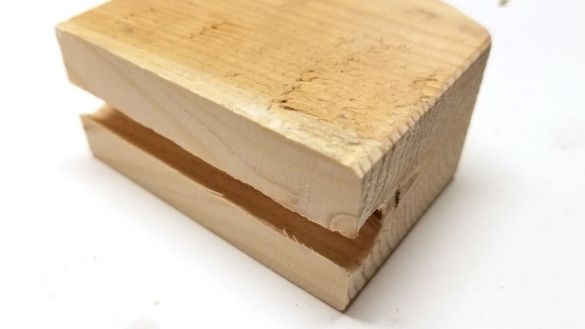

For further processing of the workpiece, the master makes wooden "sponges". In a wooden block, drills a hole and cuts the block into two parts.

Marks the place of cutting on the workpiece.

Clamps the workpiece in a vise and makes a cut.

Step Five: Soldering

Apply solder to the sleeve. Sets the sleeve to the whistle not completely. Heats the edge of the whistle with a torch until the solder melts.

Stitches the edge of the sleeve in one plane with the edge of the whistle.

Step Six: Polishing

Clamps the whistle in a lathe and polishes.

The whistle is ready.