Steak (from the English steak - a piece of meat) - a thick piece of fried meat. Moreover, fried to a certain extent. And it is better to cut it with a special steak knife, so it is less likely to hurt or damage the plate on which the steak lies. It was a couple of such knives that the Master decided to make.

Tools and materials:

- Steel O-1;

-Copper sheet;

-Copper pin;

Epoxy resin;

-Marker;

-Tape grinding machine;

-Vise;

- Sharpening machine;

- Paint tape;

-Punch;

-File;

-Clips;

-Gas-burner;

-Forge;

-Vegetable oil;

-Magnet;

- Band saw;

-USHM;

- Hacksaw for metal;

Epoxy resin;

-Wood;

-Fasteners;

-Drilling machine;

-Sandpaper;

-Oil;

-Wax;

Step One: Sketch

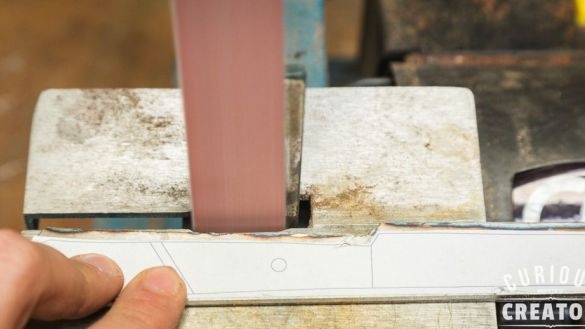

The printer prints a sketch of a knife. Sticks a printout on strips of metal.

Step Two: Processing

On the grinder gives the workpieces the desired shape.

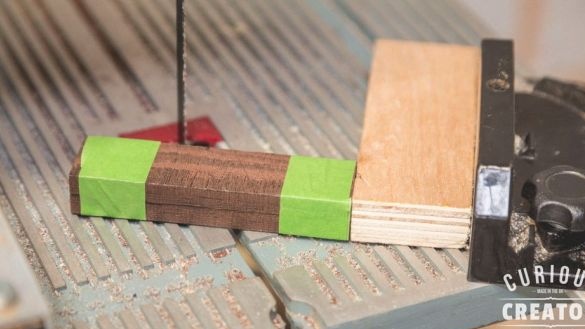

One of the conditions for the manufacture of these knives, the master considers their complete identity. To achieve this, the master glues two blanks using double-sided tape.

Adjusts the shape on a belt grinder.

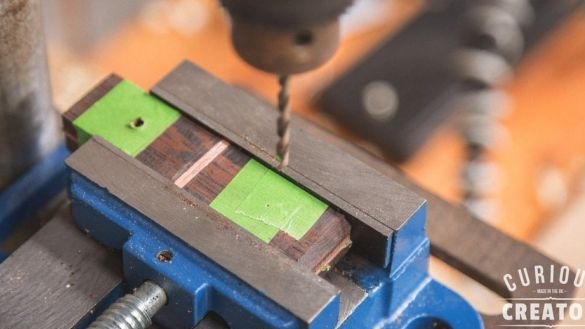

Step Three: Hole

Drills holes for pins in the handle.

Step Four: Prongs

Clamps the workpiece in a vice. Using a round file on the blade of the workpiece makes the teeth.

Step Five: Downhill

Separates two blanks. Prints downhills.

Step Six: Hardening

Next, the master hardens the knives. In the hearth, a gas burner heats the knives to the point where they stop being magnetized. Warms up for another five minutes and dips in vegetable oil.

Seventh step: grinding

After cooling, he polished the knives.

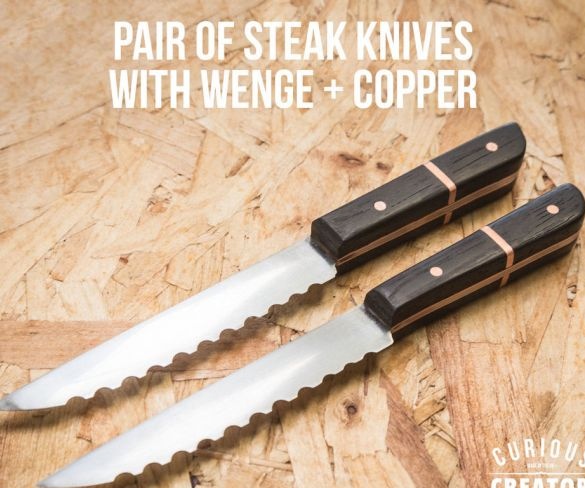

Step Eight: Pen

For the handle, the master used Wenge wood. Joins two planks together. Makes an oblique section of the block.

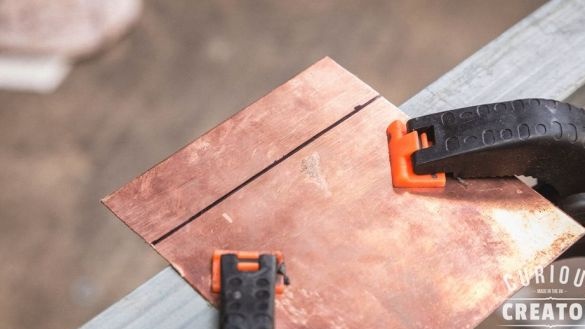

Slices two copper plates.

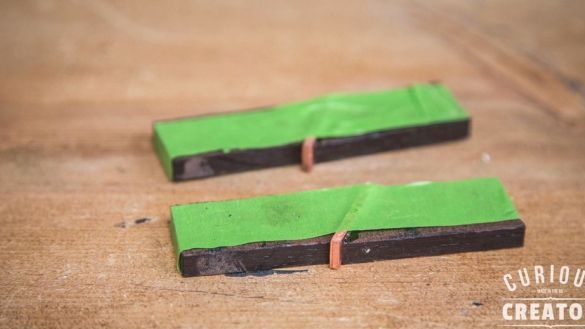

Now you need to glue these plates between two oblique cuts. The master glues on epoxy glue, and he tried to fix it on adhesive tape.

Unfortunately, this method of fixation did not pay off and the master had to make a clamping device.

While the glue hardens, the master cuts off two more copper strips.The master glues these strips to the linings from the inside. After bonding the material processes the pads.

Step Nine: Pins

Clamps the pads in a vice and drills holes.

Installs the pads on the knife. For fixing uses epoxy and copper pins.

Step Ten: Final Processing

Further, the master on the grinding machine gives the handle the desired shape. When processing it is important not to overheat the copper inserts. Then he processes the pen with oil and wax.

Steak knives are ready.

The whole process of making steak knives can be seen in the video.