I welcome fans to craft unusual things. I bring to your attention an interesting and unique knife that you can make do it yourself. Such a knife can easily be presented or just surprise friends. To make such a knife is not difficult and you do not need any special tools. The only difficulty is making a blade. The author forged it, as a result it turned out to be very strong and looks interesting. But this is not a problem, you can just cut the blade out of quality steel and harden it. This knife is folding, it can be easily and safely carried in your pocket. So, we will consider in more detail how to make such a knife!

Materials and tools used by the author:

Material List:

- sleeve from a cartridge of caliber 50 (or similar);

- blank for the blade;

- sheet brass;

- copper rod (for the axis);

- epoxy adhesive;

- dye.

Tool List:

- drill with drills;

- drill;

- blacksmith tools and oven;

- ruler;

- a hacksaw for metal;

- belt sander (preferably);

- scissors for metal.

The process of making a knife:

Step one. Prepare the handle

The handle will be made of a cartridge case. Be careful, make sure that there is no charge left in the cartridge case, and in no case do not disassemble the live cartridge, this can lead to fatal consequences. There is a dent on the capsule of the used cartridge case, and inside it is empty. We need to fill the inside of the sleeve with epoxy resin, as a result we get a sturdy case. The author adds a yellow dye to the epoxy using ordinary children's paints for drawing. Fill the epoxy, and in the nose of the liner we install a cork made of wood, this will further strengthen the design. That's all, now we leave this whole thing to dry, and in the meantime we proceed to the manufacture of the blade.

Step Two We make a blade

To make a quality blade, we need good steel with a high carbon content. Such steel will hold hardness during hardening. The author decided to forge a blade for his knife, as a result of forging, the steel becomes even stronger. If you have a blacksmith's oven and all the necessary accessories, this is the best way to make a blade. When the main profile is ready, it can be tempered, the author uses oil for this. But it is better to drill a hole for fastening first.

Step Three Finish the handle

The filler was supposed to freeze in the sleeve. Now we need a ruler and a drill.We make a cut along the sleeve, a blade will come here. We also need to make a similar cut in the front for installing the blade.

Step Four Blade revision

Now we will finalize the blade, cut off the excess and set the final profile. We also need to form the bevels on the blade and sharpen the knife, for this the author used a belt grinder. In general, such work should be carried out before hardening, but the author did the opposite.

If the steel is already hardened, it must also be let go, which is what our author decided to do. To do this, he warmed the blade over the coals. A moment was waited for the metal to become a straw color, this will indicate that the vacation turned out. But this, of course, is not professional, hardening and tempering should be carried out depending on the selected steel grade.

Step Five Finishing touches and knife assembly

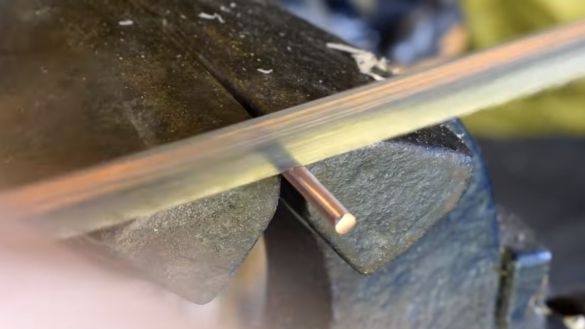

In conclusion, we will need to make a fixing device for the blade so that the knife does not fold itself. The author made this detail from sheet brass. As for the axis, it was made of a copper rod. It is better to use steel here, such an axis is stronger and more durable. Although copper looks more interesting.

That's all, the knife is ready, it remains to sharpen it. For these purposes, the author used a Japanese water stone. We sharpen the blade to the state of the blade, wetting the stone with water. That's all, the project is over. Everything turned out pretty interesting, I hope you enjoyed it. Good luck and creative inspiration, if you decide to repeat it. Do not forget to share your homemade with us.