Portable firewood for stove and fireplace

How pleasant it is to spend cold autumn and winter evenings, basking in the stove or fireplace! Only one thing can spoil the atmosphere of comfort - the need to go outside for a new portion of firewood. But if you already have a special stand for storing firewood in your house, you won’t have to leave your comfort and wander in the cold and bad weather for firewood.

In addition, anyone who drowns a stove or fireplace knows that along with firewood, trash and dirt are brought into the house, and therefore storing them directly on the floor is unacceptable. It will be much cleaner when they lie not far from the stove in a small stand for firewood - firewood. And if you bring firewood to the stove in advance, then they will have time to dry and burn faster, and also give more heat when the stove is burning.

However, no matter how much firewood you put in the drovnitsa at home, sooner or later you will still have to go out to replenish their supply. In order to conveniently bring and use firewood, it is necessary to have a portable mini-firewood on the farm.

The easiest way to get a woodcutter is to purchase a finished product.

Today on sale you can find a huge assortment of firewood from a wide variety of materials that will wonderfully fit into your interior and provide convenient operation. Most often, metal models are chosen, as they are more reliable and convenient. They will be an excellent element of home decor and will last you more than one year.

There are various metal, including forged firewood for fireplaces. Although these products look great, sometimes they are too heavy and bulky, and besides, they cost a lot of money. But in any case, firewood made of metal will be a very useful solution for a country house. Not only on the basis of aesthetic needs, but also on fire safety conditions.

The choice of firewood for purchase is really large, but how pleasant it will be to use a firewood made do it yourself. Moreover, it is not difficult to make it even for a beginner, without the high cost of money, effort and time.

Based on this, it is proposed to make a light and openwork firewood, made in the style of minimalism.

From materials and tools you will need:

- 3 metal (reinforcing) rods with a diameter of 8 mm, a length of approximately 1.5 m.

- a metal sheet with a thickness of 0.50 ... 0.75 mm, a size of 600 x 800 mm.

- welding machine and "grinder".

Work execution order:

1. By any means at hand, bend 2 identical rings with an inner diameter of 45 ... 50 mm from the bar. Similarly, make 4 rings with an inner diameter of about 70 mm.

The bending of the rod can be performed on a bending device, on a mandrel, cut from a spring wound on a pipe manually or on a lathe. After editing to the desired size and flatness, cut off the excess parts of the workpieces so that between the ends of the finished ring there is a gap of about 10 mm. This clearance is necessary for subsequent structural adjustments.

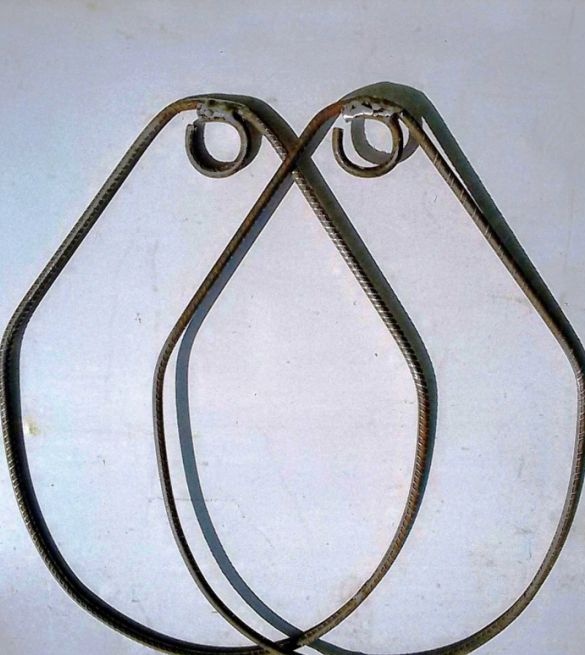

2. Form two identical blanks from metal bars. These details will constitute the supporting foundation of the structure. The lower part of the workpiece is a semicircle with a diameter of about 400 mm. In the upper part, the ends of the arc converge in a straight line, go into a diameter of 60 mm and are butt-welded. There, the previously made ring fits in and welds. The gap, when welding the ring, should remain open. In this ring then you will need to install a wooden handle to carry the entire structure.

The dimensions of the parts manufactured according to p. 1 and 2 are approximate and correspond to the author's version. Their sizes can vary within wide limits, depending on the tastes and needs of the master.

3. At the bottom of the workpieces, in the plane of the part, the two remaining rings are welded (see photo). They play the role of the legs of the structure. Therefore, when welding, they are positioned so that when installing the finished part on the legs on the floor, there is a gap of 15 ... 20 mm between the workpiece arc and the floor. The ring under the handle should be at the top of the workpiece. When superimposed, the contours of both workpieces must be symmetrical and match as closely as possible.

4. We select metal for the manufacture of a pallet for firewood. In the proposed design, for this purpose, a side wall from the idle washing machine was used. Its advantages are a professional coating and L-shaped ribs around the perimeter, which give the sheet a certain rigidity. Sheet thickness - 0.75 mm. Dimensions - 600 x 800 mm.

5. We bend the sheet on a cylindrical mandrel (log), with a radius slightly larger than the radius of the lower part of the load-bearing blanks (item 2). The height of the cylinder is 600 mm.

In opposite lateral ribs of the sheet, we symmetrically mark out and cut (to the cylindrical surface) two grooves with a width of 8 mm (bar diameter). See photo. The distance between the grooves is taken based on the length of the shortest logs. In the proposed design, this distance is equal to half the length of the pallet - 300 mm.

6. The material for the handle of the drovnitsa is a wooden shank for a shovel. It is lightweight and durable. The tree is comfortable to use (does not burn or freeze hands).

We cut the stalk of the desired length and insert it into the rings of the bearing blanks, expanding them if necessary. The distance between the rings is equal to the distance between the cut-out grooves in the pallet.

We fix the handle by squeezing the rings with a hammer, until they are removed or rotated on the handle.

7. After painting the assembled structure, install the pallet in place. We slightly reduce the edges of the pallet and bring it into the previously assembled structure (item 6), until the bars of the workpieces coincide with the grooves of the pallet. Due to the elasticity of the pallet sheet, it is revealed and fixed in the design of the woodcutter.

A possible pitching of a firewood installed on a flat floor, after assembly, is easily eliminated by compression or opening (changing the diameter) of one of the rings - legs.

8. Operation of the firewood for a month, showed sufficient structural strength and ease of use. The small size of the firewood makes it easy to bring firewood and conveniently place them near the stove. For the summer, the woodcutter quickly disassembles into components for compact storage. However, wishes were expressed for even more weight reduction designs.

9. Since only the pallet allowed reducing weight, its second version was made of galvanized sheet with a thickness of 0.55 mm. The weight of the firewood was noticeably reduced, but the sharp edges of the thin metal posed a serious danger. Therefore, the edges of the cut galvanized sheet were pre-flanged (wrapped in the form of a tube), sharp corners were rounded, and fixing grooves were formed in the flanging.

The functional properties of the portable firewood after this refinement only improved.