This article will be interesting to everyone who has to deal with metal small parts and garbage like chips.

The author of the channel "Made in Poland" offers a solution to the problem of cleaning chips with a magnetic picker.

Materials

- Copper or aluminum tube 22 mm x 330 mm

- Handle from a motorcycle or bicycle

- Steel pin M5 340mm long

- Two plastic caps

- 6 neodymium magnets 20mm x 3mm. (There are eight of them in the pictures, but the author took two - six are enough)

- 12 washers m10

- 12 washers m5

- 9 nuts m5

- One extended nut m5

- Plastic handle - lamb with m5 thread.

Instrumentsused by the author.

- Lathe. Optional

- Drill or screwdriver

- Anvil, hammer

- Wrenches, pliers.

The author is convinced that if you do not have a lathe, you can also make such a magnetic collector for small metal waste. The main thing you need to do is find magnets with an outer diameter of about 20-21 mm.

Washers are required for proper collector operation. Thanks to them, all magnetic forces are transmitted to their sides (for example, a welding magnet).

Yes, the author drilled neodymium magnets. But he has no idea whether you can do it or not, but they work fine, and nothing bad happened to them. (Because they crack during drilling.)

When you drill them, do not forget, do not overheat them, because they will lose their properties. It is better to do this in a few calls.

Assembly process fixtures.

First you need the M5 washers and bolt.

The author collects a bag from them, clamping it with an elongated nut and a regular counter.

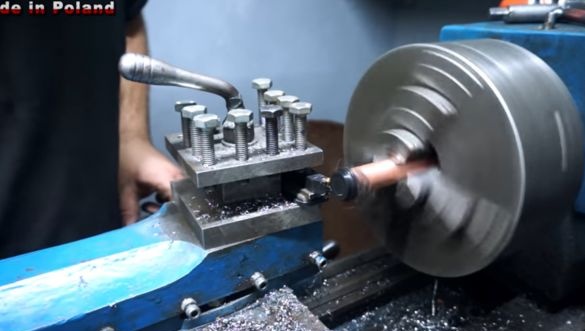

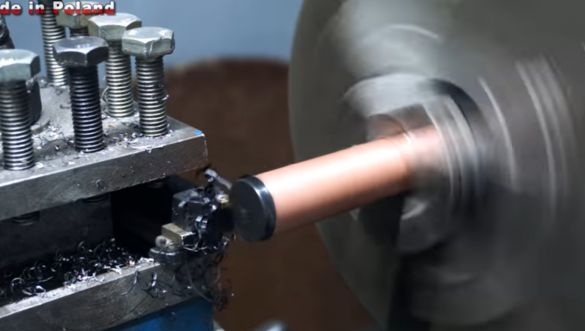

Now, clamping the bag by the elongated nut in the lathe chuck, grinds the washers slightly so that they become the same size.

Then he parses the bag and removes not turned washers.

With sharpened, there is still a slight refinement.

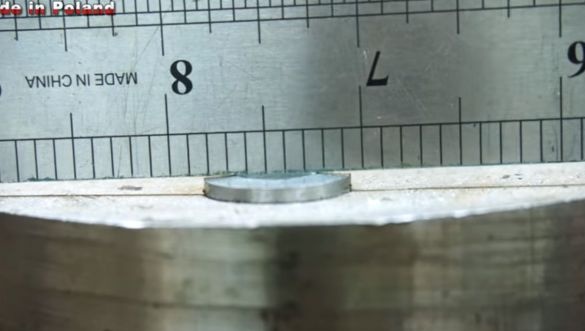

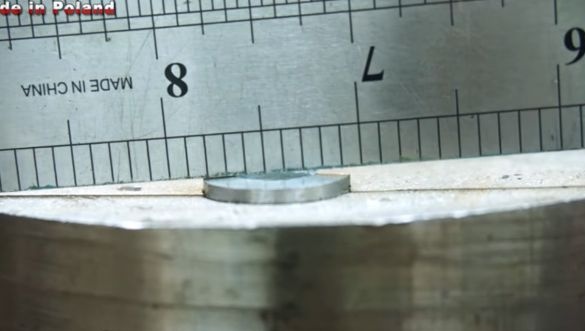

Having laid the washer on the anvil, and having placed the ruler, it is clear that it is not flat. This is due to the technology of its manufacture. Covers the puck with a steel plate, and smoothes it with a hammer. The author needs 12 such washers.

Now the puck has become flat, you can move on to the next process.

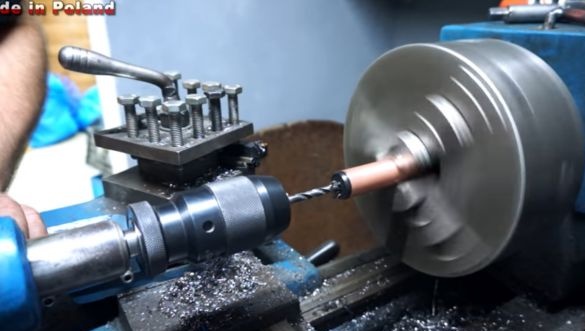

Such neodymium magnets could get the author. But the hole in them is small. In order for the magnets to fit on the M5 stud, they need to be drilled. Very neat and without overheating.

Now the magnet fits on the hairpin.

The next step will be the assembly of the working part. First of all, it clamps the stud in the screwdriver's chuck, it will be easier to tighten the nuts. It gains the original nut and, holding it with pliers, brings it to the right place.

The package itself collects from eight repeating elements. Each element of the package is assembled as follows: washer M5 - washer M10 - neodymium magnet - washer M10 - washer M5 - nut.

You can magnetize M10 washers immediately, it will be faster and easier to assemble.

After assembly, the bag fixes it at the end with two nuts and compresses the entire structure to the very edge of the stud.

Now he runs it several times through a copper pipe so that everything goes freely.

At the beginning of the tube inserts a cork. She sits very tightly, even had to help with a hammer.

Installs the housing in a lathe, and grinds cork bumps. Drills a hole for the stud.

Passes the working part through the pipe, pulling the pin through the cork. The second edge of the tube closes with the same plug. Clamps in a cartridge and repeats the action, as with the first. But does not drill a hole.

The next one will be a handle, in its "bottom" drills a hole with a screwdriver.

Puts the handle on the finished case, pulls out the hairpin.

Screws a nut and a knob on the edge of the stud, clamps them together with a key.

It works great.

It's time to start the test. Pushing the working part all the way, collects the scattered chips.

To dump collected in a bucket - it is enough to sharply pull the working part by the lamb.

You can even see where each magnet is located. You can collect not only chips, but also randomly scattered nuts, washers, bolts. In general, the use of such a "broom" mass. You can also look for a fallen small bolt or spring.

The whole structure works very well, and the author recommends it for mandatory production. And since the construction is sealed right up to the handle, it is possible to search for a fallen part even in a dirty puddle.

Thanks to the author for a very useful idea for the workshop!

All more exclusive tools!