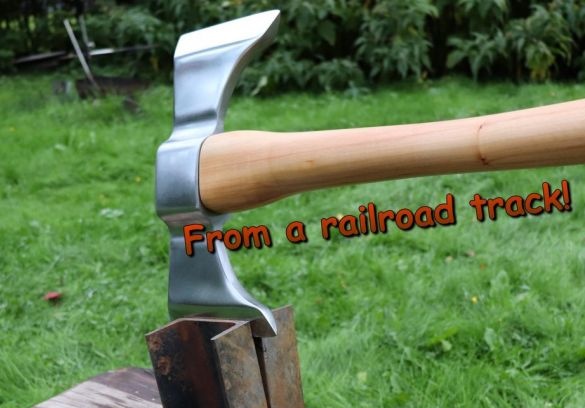

This ax Master made as a gift. The ax is made of a 30 centimeter piece of rail weighing 18 kg. The weight of the finished product is 8 kg. To make an ax, the master used the following

Tools and materials:

-UShM-180;

UShM-125;

-Welding machine;

-Vise;

-Grinder;

-Wooden bar;

-Hammer;

- Vibropila;

-Rail;

Epoxy resin;

-Linseed oil;

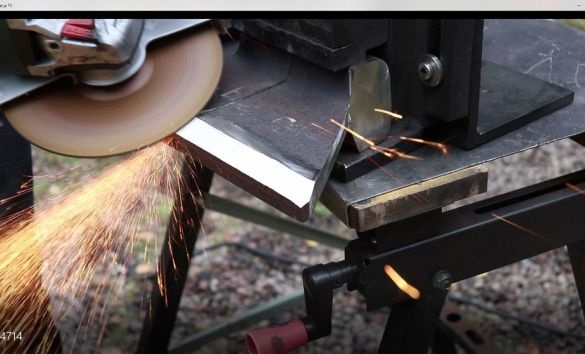

Step One: Outsole

Clamps the rail in a vice and cuts the sole on both sides. Then it polishes the neck of the rail in one plane.

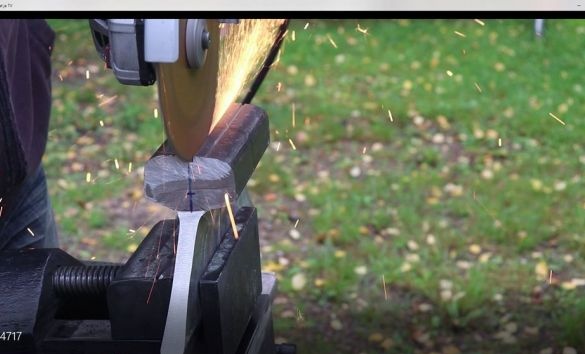

Step two: shaping

Cuts wedges on both sides of the rails.

Draws the blade of an ax.

Step Three: The Eye

It makes incisions in the rail head and then cuts out the eye.

Step Four: Ax Handling

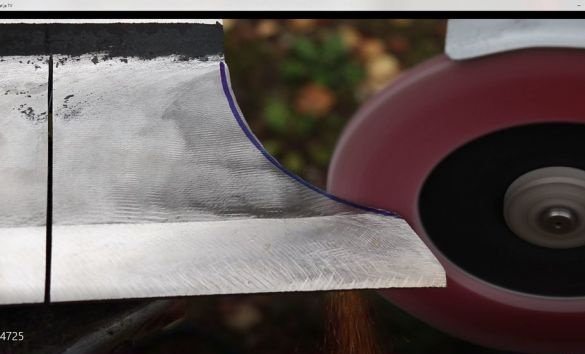

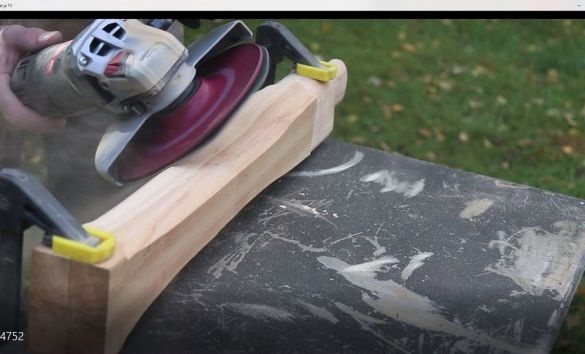

Turns an ax. Removes bevels, polishes.

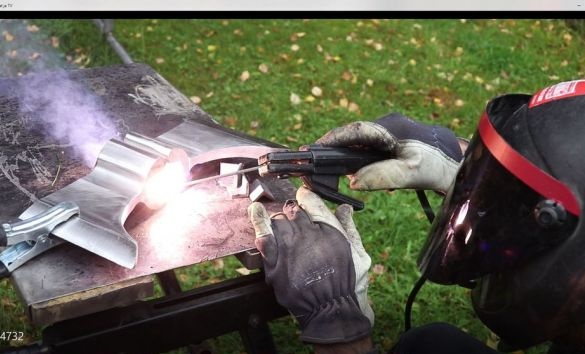

Step Five: Welding

Cuts the workpiece into two equal halves. Heats the billet in the oven to 100 degrees. Welds two workpieces together.

After welding, he polished the seams.

Step Six: Eye and Blade

Sharpen an ax blade. To install the handle handles the eye.

Seventh step: pen

Makes a pen.

He puts an ax on the handle after lubricating the junction with epoxy resin. Scored a wedge. I cut off the extra part of the handle. Processed the handle with linseed oil.

The ax from the rail is ready.

The entire process of manufacturing an ax can be seen in the video.