The master made several models of grinding machines. And manual, and stationary, and combined. Another creation of the master, device for a drilling machine. With the help of this device you can work with a petal circle, brush, sandpaper, felt. A drilling machine is used as a drive, and the gearbox is taken from a broken angle grinder. Installing the tool on the machine, as well as replacing the wheel takes a matter of seconds.

Tools and materials:

-Screwdriver;

-Mites;

-USHM;

-Welding machine;

-Drilling apparatus;

-Sheet metal;

-Fasteners;

-Press;

-Vise;

-A screwdriver;

-Clamp;

-Broken angle grinder;

- Keys are metalwork;

-Aerosol paint;

-Crown for metal;

-Plastic;

-Tape grinding machine;

-Metal tube;

-Hammer;

-Various grinding wheels;

Step one: disassembling angle grinder

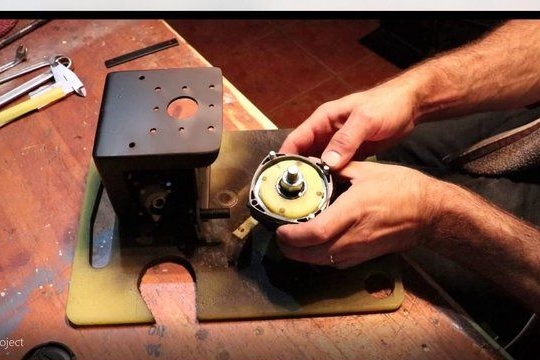

First, the master parses a non-working angle grinder. To adapt you will need parts of the gearbox, the armature shaft, part of the housing, bearings. The master cuts the anchor to the shaft, and then extrudes.

Step Two: Plate

Turns the shaft to install the bearing. Bearings will stand on both sides of the plate.

From a metal sheet makes a plate. On a sheet outlines the contour of the gear housing. A hole for the shaft is drilled in the center of the plate. Along the edges for mounting. Then cuts it to the desired size.

Step Three: Gearbox Assembly

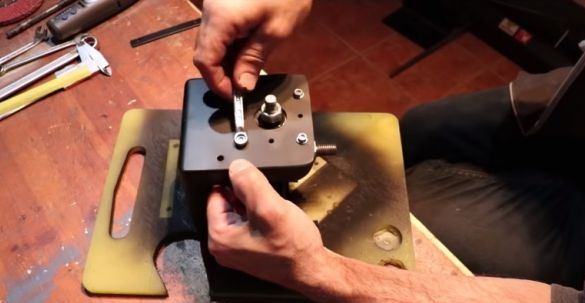

Clamps the shaft in a vice. A bearing, a washer, a plate are mounted on the shaft.

Installs a plastic part from Ushm. Puts a second bearing, gear reducer. Fixes with a nut.

Mounts gear housing.

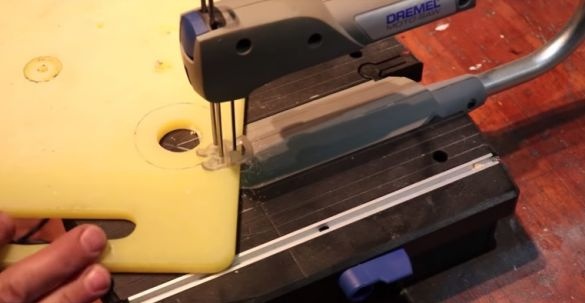

From plastic cuts out the seat for the upper bearing.

Step Four: Frame

The frame consists of two L-shaped halves. In the upper part of the frame, the master makes a hole for the gearbox shaft and fasteners.

Mounts on the gearbox and checks the alignment of the holes. For fastening, cuts the thread.

Cuts off the plate.

On the press bends.

The bottom of the frame is the same in shape as the top. The bottom plate of its plate has a hole for fixing to the working table of the drilling machine.

Installs the device on a drilling machine. Combines two halves of the body. Fixes them with clamps.

It grabs two halves together.

Step Five: Base Plate

Makes support and side plates.

Step Six: Welding

Scalds connections. Grasps the bolt of the base plate.

Cleans the seams.

Seventh step: painting

Removes the gearbox and paints the case.

Step Eight: Final Assembly

Screws the gearbox to the housing.

Clamps the shaft in the drill chuck. Screws the housing to the machine table.

Screws the base plate and sets the grinding disc.

Everything is ready. Next, the wizard shows the device in operation. As you can see, mounting the device and replacing the drives does not take much time.

The whole process of manufacturing the device can be seen in the video.