In this article, which is very useful for us working in our workshop, both with metal and with other materials, we will again focus on marking devices. Indeed, the correct and accurate layout of the workpiece is the key to success in the finished product.

The author of the Be Creative channel has something to say about this. He made a marking pencil from a brass rod and an old broken drill.

Materials

- Brass bar, diameter 10-18 mm, at the discretion of the user.

- Old broken drill 2-6 mm.

- Epoxy two-component resin, or super-glue.

Instrumentsused by the author.

- Band-saw.

- Lathe, cutters to it.

- File.

- A set of sandpaper of various grain sizes.

- Vise.

- A grinder with flap grinding discs.

Manufacturing process.

So, the author proceeds with the processing of the brass bar.

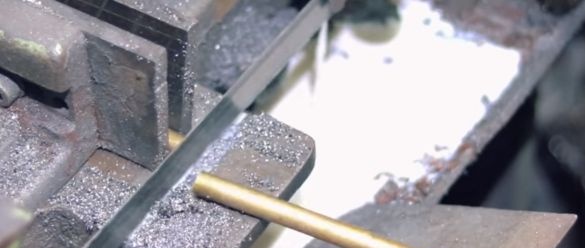

Grips him in the grip of a band saw.

It starts the machine, and cuts off the workpiece of the required length - in size like a fountain pen.

Sets the workpiece in the lathe chuck, clamps it.

Grinds the end of a brass bar.

Turns over the workpiece, also processes its edge.

Then he drills a hole in diameter, slightly larger than that of the drill being installed. Periodically pulling out the drill from the workpiece to exit the chips. Brass metal is relatively soft and viscous.

He rotates the headstock at an angle of 30 degrees, processes the second edge of the workpiece, turning it into a kind of sharpened end of the pencil.

Smoothes out irregularities in the cutter with a file.

The next step is a notch on the working side of the bar. In order that the "pencil" would not slip in the hands.

Grinds the "front" side of the workpiece with sandpaper.

Turns over the workpiece and processes its second side.

Cuts a notch.

A cutter makes an old and broken drill, sharpening it on a sharpener. Moreover, clamping it in a screwdriver, for proper alignment.

It mixes the components of epoxy resin, dips the tip of the drill into it, sets it in the hole of the brass “pencil”.

After the resin hardens, it cleans. It turns out here is such a tip.

Here is a notch after rough grinding.

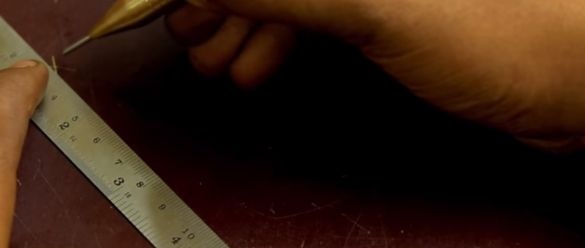

The tool is ready, trying to mark on fiberglass.

The results are quite remarkable. Of course, this tool can also be processed on polishing wheels using GOI paste. But the author of this quality is enough.

Thanks to the author for a simple but good idea for the tool needed in the work!

Good luck to all!