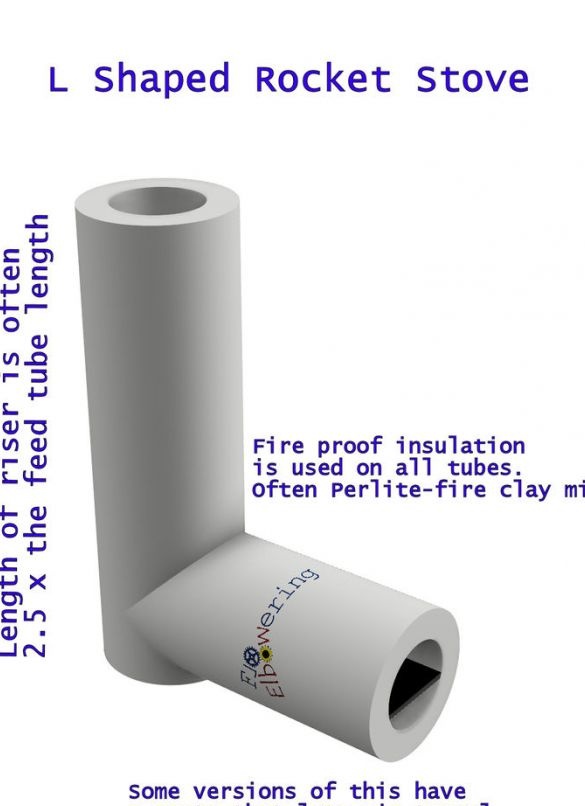

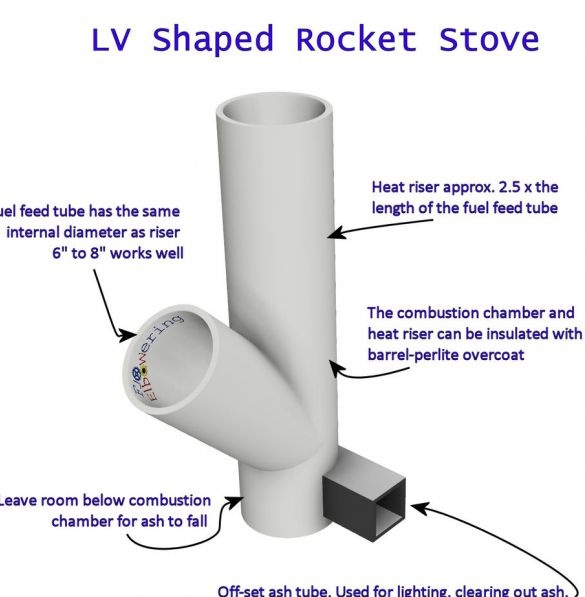

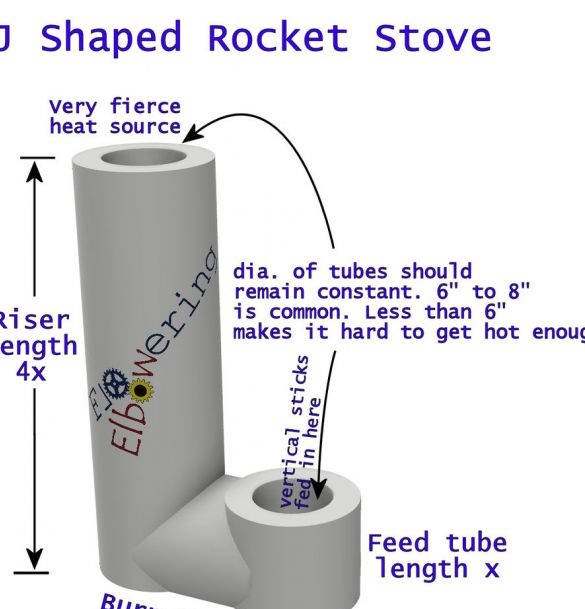

The rocket furnace, thanks to its parameters, has gained popularity around the world. Unpretentiousness to fuel, good heat transfer, simplicity in manufacturing are the main advantages of such a furnace. By the way, a rocket stove is also made in residential premises for heating and cooking, write, and not just as a "marching" or "street" option. There are several options for building such a furnace. The master combined two such variants of photo 1, and 2., and made his photo 3.

For the manufacture of the master used the following

Tools and materials:

-Oxygen balloon;

-Cardboard;

-Marker;

-Insulating tape;

-USHM;

-Magnetic square;

-Welding machine;

-Profile;

- Band saw for metal;

-Channel;

-Roulette;

-Metal brush;

-Hammer;

Clamp;

-Metal capacity;

-Pliers;

-Bolt;

-Two bushings;

Perlite;

Step One: Cylinder Cutting

For proper functioning of the furnace, its vertical part should be 2.5 times longer than the fuel chamber. With this in mind, the master makes the marking of the cylinder. For an even cut, a piece of cardboard is wrapped around the container, aligns the edge and outlines with a marker. When marking volumetric parts in this way, you can be sure that the cut-off location is even.

Then the master cuts off the cylinder according to the marking.

Step Two: Boot Camera

Now you need to correctly cut the edge of the boot chamber. The master makes a template out of paper. Moves the template to the workpiece.

Cuts by markup.

Step Three: Loading Hole

Using a magnetic square, fixes the loading chamber on the workpiece. Traces it along the contour from the inside and out.

Cuts a hole.

Checks mating, adjusts if necessary.

Step Four: Ashpit

The ash pan provides access to the combustion chamber, also with its help you can control the draft. The master made an ashpit from a profile pipe 100 * 100 mm. Cut off the desired size.

Fitted along the radius of the pipe.

I cut a hole in the pipe.

Step Five: Swirl Flow

To ensure greater traction, the master makes fresh air ventilation. The pipe will draw in air and passing through a curved pipe will increase traction.

Cuts the shelves of the channel.

Notches.

Bends the edge of the workpiece around the pipe.

Step Six: Welding

All parts are prepared and you can start welding.

Welds the boot chamber.

He grabs an ashpit.

Now you need to measure where to cut a hole for the ventilation.The master applies the workpiece to the ash pan and outlines the diligence site of the curved part.

Cuts a hole.

Welds the workpiece, scalds the ash pan.

Seventh step: thermal insulation

To insulate the upper part of the riser, the master uses a barrel. Cut a hole in it. Makes the "petals".

He puts a barrel on the pipe.

Subsequently, the master filled the inner space with perlite.

Step Eight: Gas Afterburning System

To improve the efficiency, the master makes a system of afterburning gases. Rising air through the chamber will fall into the upper part of the furnace and mix with the gas. Due to the influx of oxygen, the gas will be burned out.

Of the channel makes the box.

Marks a hole in the furnace body.

Cut a series of holes and weld plates on them.

Welds the box.

Step Nine: Cover

For the ashman, the master makes a lid. The cover is fastened with a bolt and two bushings machined on a lathe.

Step Ten: Prop

For safety and stability from below, the master welds the plates.

The rocket stove is ready.

Subsequently, the master improved the furnace and added a hob to it, but more on that in another article.