This article will be very useful to everyone involved in the processing of wood and the manufacture of homemade products from it. From it you will learn how the author of the "Gökmen ALTUNTAŞ" channel made a simple tool that allows making round dowels with a diameter of 6, 8, 10 mm from square blocks.

Everyone knows that even with modern methods of joining wooden parts, standard methods simply can not do. One of them is a dowel connection method.

This homemade product does not require a heavy tool and a lot of time, it can be done in literally 15 minutes.

Materials

- Steel plate 100X40 and 4 mm thick

- A block of hard wood 100X40X25 mm

- Suits 11-12 mm thick

- Lubricant coolant

- Two screws.

Instrumentsused by the author.

- A circular saw

- Drilling machine

- Vise

- Screwdriver

- Drills 2, 3,5, 6, 7, 8, 10 mm

- Ruler, marker

- Stationery knife, dust brush.

Manufacturing process.

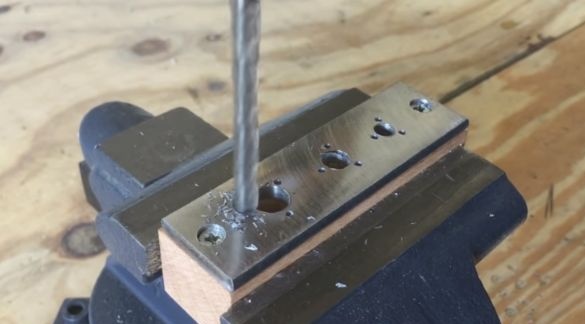

The author begins by drilling holes for fastening a steel plate.

The hole itself is drilled with a diameter of 3.5 mm, then makes a hole for the head of the screw with a 7 mm drill.

Then it fixes a steel plate on a wooden block; it should be made of hard wood. A 2 mm drill makes holes in the bar so that it does not crack when the screw is screwed.

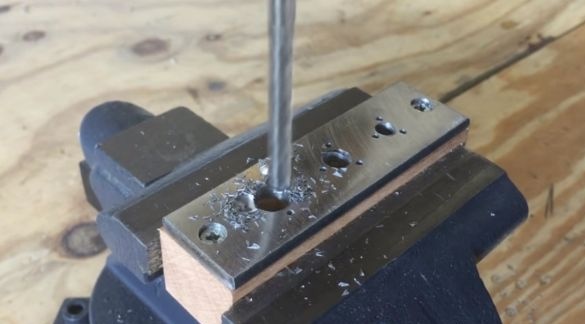

Now, using a drilling machine, drills 3 holes of various diameters.

First 10, then 8 and 6 mm. These will be the diameters of the dowels obtained. You can choose the ones you need.

The holes are drilled through. It is very important not to overheat the steel plate, the author uses coolant (cutting fluid).

Secures the workpiece in a vise, marks three points around each hole at a distance of 2.5 mm. And drills a 2 mm drill, not necessarily through a steel plate.

Now, according to the planned 2 mm holes, he drills a 7 mm drill, this will turn out some kind of incisors.

Attention, you can’t drill through it, just cut the edge of the guide hole a bit and make it sharp.

This is how the finished tool looks.

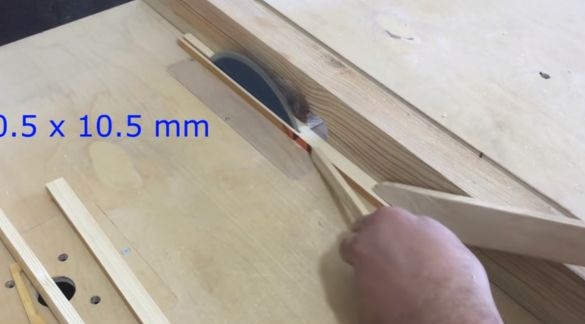

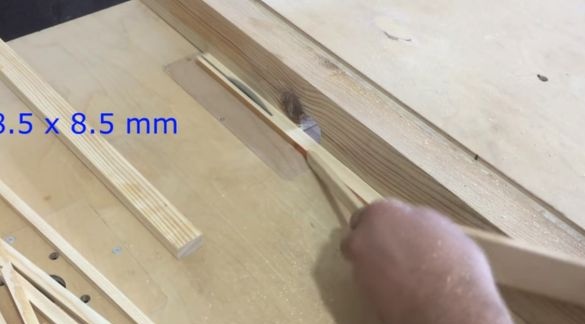

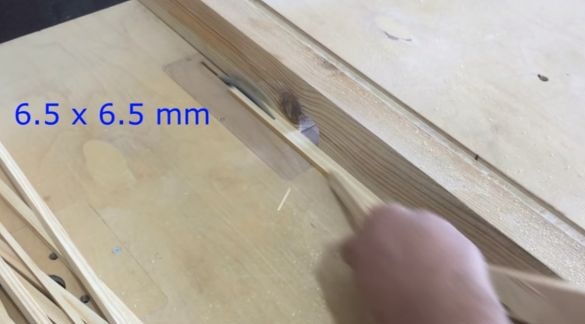

Then cuts cubes of square section. With dimensions 10.5X10.5 8.5X8.5 6.5X6.5 mm.

It remains to slightly strip the edges with a knife for better alignment.

It's time to experience! Clamps one edge of the block in the chuck of a screwdriver, inserts the second into the cutter. First he tries to cut a 10 mm dowel.

The next will be 8 mm.

And the thinnest is 6 mm.

These dowels are obtained.Everything is smooth, and small roughnesses will only improve the adhesion of the dowel to the material and glue. It remains only to cut these pieces into pieces.

Thanks to the author for a great idea for a very useful, albeit simple, tool!

Good luck to all!