This article will be interesting to masters working with metal, namely those who are engaged in welding work.

In it, the author of the Samodelki Vitmana channel will show and tell which device he did and it can greatly facilitate your work. With this simple construction, you can connect two parts together. You can connect both sheet materials, and channels, corners.

For the manufacture of this homemade product does not require much time and a heavy tool. Actually, the welder himself can make it directly at the facility from improvised materials.

Materials

- 2 studs on M12 60 mm long.

- Two sections of a profile pipe 40X40 mm.

- Steel plate 2 mm thick.

- Two bolts with nuts on the M3.

- A pair of wing screws on the M12.

- Two pieces of wire with a diameter of 6 mm.

- Spray paint.

Instrumentsused by the author.

- Bulgarian with disks

- Drilling machine

- Drill or screwdriver

- Drill

- Vise

- pliers

- Caliper.

Starts the manufacturing process.

To begin with, the author marks the sections of the profile pipe with a caliper.

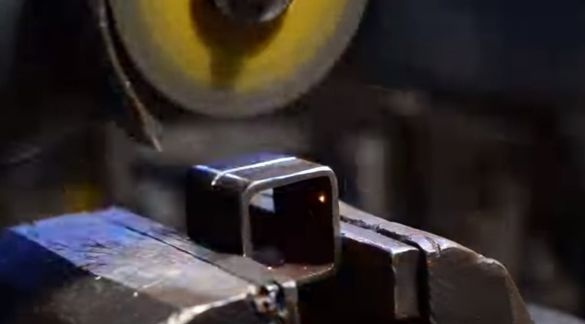

Then, holding the workpiece in a vice, and using a grinder with a metal disc, he makes a gash in the marked place.

On the back of the workpiece marks the center, and makes a hole with a diameter of 12.5 mm.

From a steel plate 2 mm thick cuts two equal parts.

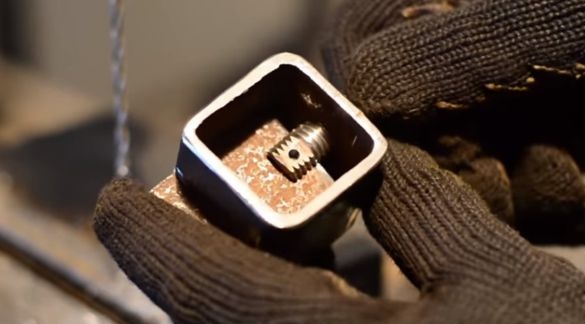

And it adjusts them to the internal dimensions of the profile pipe.

Drills holes with a diameter of 6.5 mm in the plates.

Clamps the hairpin in a vice and makes a cut from the end of the hairpin, parallel to which it makes a gash from the outside.

Here is the end face of the blanks should work.

Further, in the studs, he drills holes for the M3 bolts.

Assembles the structure, attaches the plate to the stud and makes a hole similar in diameter to it.

The resulting parts are painted using spray paint.

The paint has dried, It remains to collect all the parts together. It fixes the stud and plate between itself with a bolt and an M3 nut.

Well, the device is ready, you can try it in work. As subjects, the author took two corners, with the help of his device connects their edges. To do this, the plate is inserted between the edges of the corners, then a wire is installed in the hole. And the lamb drags on.

As you can see, this device does an excellent job of the task.

Thanks to the author for the interesting idea of a welding fixture.

Good luck to all!