I hope this article will be useful for everyone working in their workshop or at home. It will focus on the classical instrument - the hammer.

The author of "Be Creative" decided to make a lightweight, or "soft hammer." One problem in manufacturing - you need a lathe.

Materials

- Aluminum round timber and bar.

- A pair of brass bolts.

Instrumentsused by the author.

- Lathe

- Cutters for a lathe

- Drilling machine

- Band-saw

- Vise

- Lerka, taps

- Knurling nozzle.

Manufacturing process.

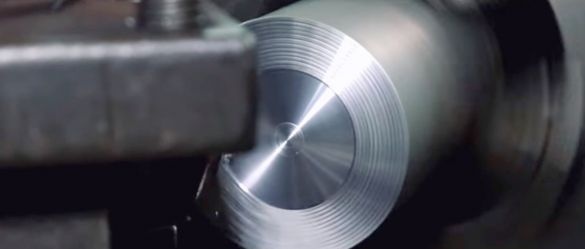

The author begins with the manufacture of the hammer head, turning it from an aluminum round saw. Clips a round in the lathe chuck and processes one side of the hammer.

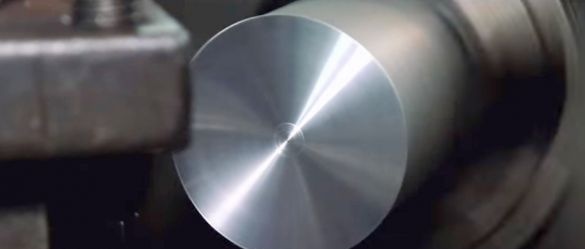

Then he turns over the blank and processes the second side. It also cuts decorative stripes on the cheeks.

Processing of the head is completed, the next step, the author pitches the place for mounting the handle.

Clamps the workpiece in a vice, laying soft material, so as not to damage the head. Drills first small diameter, then large.

Then, using a tap, cuts the thread in the hole.

A handle is made from an aluminum bar. Standard edge treatment.

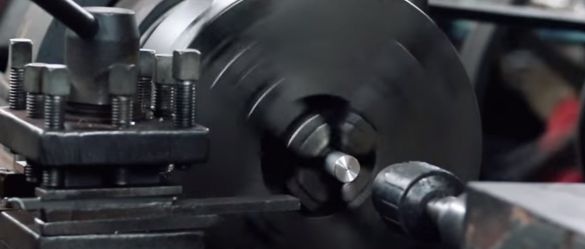

It fixes the workpiece with the help of the tailstock, sets the knurling nozzle, and applies a notch.

At one end of the handle removes excess metal, cuts the thread.

At the second end, drills a hole, cuts a thread for a decorative bolt.

Processes a brass bolt.

All parts are ready, you can assemble the product.

That's all, the tool is ready!

Thanks to the author for an interesting idea! I am sure that such a hammer can well be presented to a friend of the master.

All the good tools!