Initially, the goal of Bonn Factory’s YouTube channel author was to conduct an experiment, simultaneously pour 2 molten metals into one mold and see what came of it. But in the end, he decided to show in detail the entire process from simulation to processing.

The author also admits that some of his methods for achieving the goal are different from the textbook ones, so this homemade product should be taken as a work of art.

As a basis, it was decided to take a finger of the 21st size, as the most popular in practice. Due to the shrinkage of the metal after casting, the ring will become smaller by half the size, but thanks to its thick walls we can stretch it to three sizes.

In order for the wax to lay on the caliber evenly and painlessly removed from it, you need to slightly warm the metal, and apply a release agent for wax. Then, briefly dipping a finger in the molten wax and removing it, let the wax solidify a little, and then repeat the operation until the desired layer thickness is reached.

Then with a knife we cut off excess flows. From this blank we will make the shred of our ring. You probably wonder: why is this necessary, because the wax already has a finished look? Well yes, it is. The author finished it at the time of removal of the silicone mold. But the modeling skills do not stand still and each time the cutter in the author’s hand is more and more confident, the eye notices more details, and there is no limit to perfection. It is for these reasons that the ring needs to be fixed before pouring, to make the splint more harmonious, and the details of the skull more expressive.

See how the shape changes. The author slightly changed the eye socket and temples, as well as the angle of the face, adding a tangible mass of wax under the jaw.

Ahead we are waiting for work with the nose and refinement of details, drawing textures and lines of bone growth, and adding all the necessary cavities. The author also thought that he would make this shard completely toothless. He had never allowed this before, so this ring is not only unique in that the author, like all other rings, does it manually, starting only with a draft, there have never been such toothless cases in the master's practice.

Remember, the author decided to fill in 2 metals at a time? That is why it turned out such an arrangement of the ring with such a number of sprues uniformly suitable for all parts of the ring from one large one.

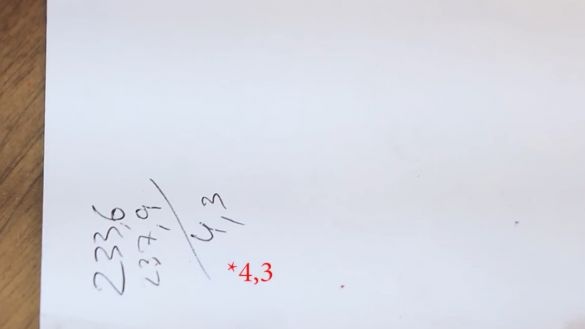

4.3 grams weighs our wax with sprues, which means that in total we need about 43 grams of metal to fill the entire system.

Fill the flask with molding material and set it to calcination. The filling process has become quite exciting for the master, literally before the pulse increased. So much he was involved in the process and worried about him. The master and assistant had to heat up 2 crucibles with metals at the same time and also pour them at the same time. And we will pour in this experiment cupronickel and brass. These are 2 copper alloys that should be perfectly alloyed with each other. Also, everything had to be done quickly and decisively.

Well, here it is the result.

It was not ideal to pour metals at the same time, so most of the ring became brass and only on the surface can nickel silver stains be seen, most of which will be erased during polishing. In general, an interesting pale yellow alloy was obtained. It is also interesting that the bulk of nickel silver is visible on the inside of the ring splint, there almost everything is covered by a layer of gray metal, but again, only superficially.

After mechanical work with the ring, degrease it by warming to red and lowering it into water, and also let it stay for a bit in an ultrasonic bath.

Then, without touching hands, we apply sulfuric ointment, and also heat the ring with a burner.

Well, that's all for today. Thank you for attention. See you soon!

Video: