Materials

1. Micro-aircraft engine

2. Motor from a screwdriver

3. A square steel pipe (the author did not give the sizes, if there is a video below)

4. Organic glass

5. Saw (old, unnecessary)

And all sorts of drill tools, lathe, etc.

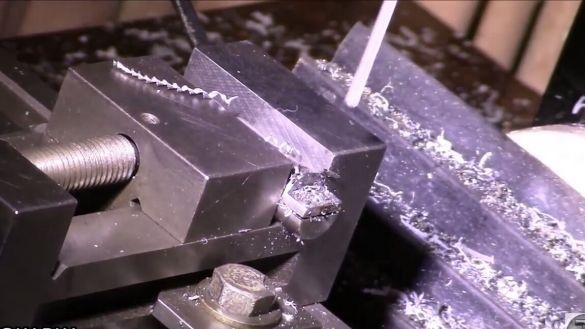

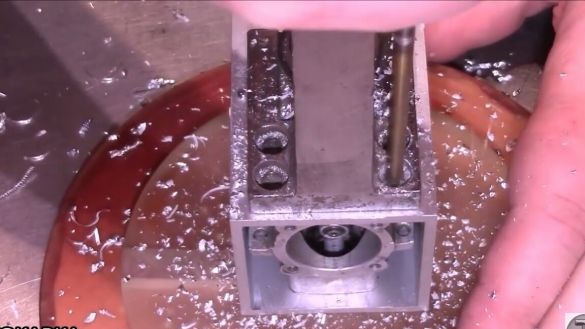

Step 1: making the case

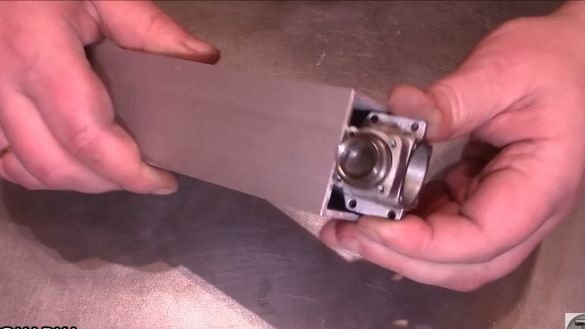

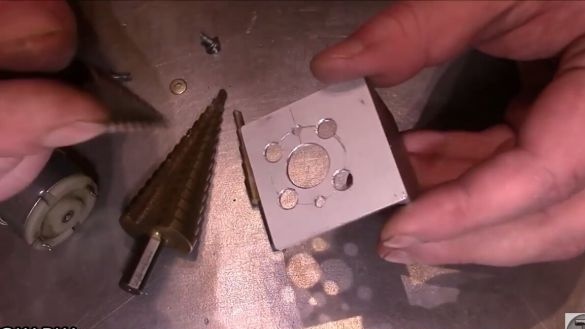

Using a lathe, the cylinder is shortened to move the piston. Of the square profile, the body is made. To exit the engine piston to the outside of the housing, the author, using stepped drills, makes a hole of the desired diameter (for the piston) and for fixing the cylinder.

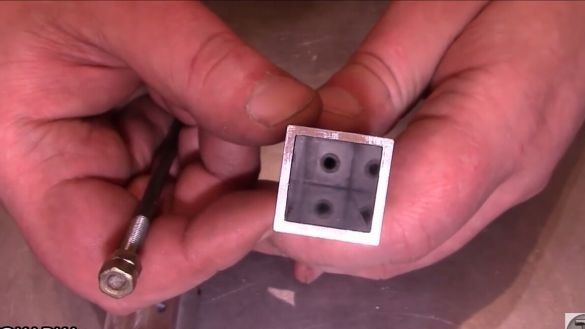

Step 2.Manufacture of an adapter and fasteners for a motor

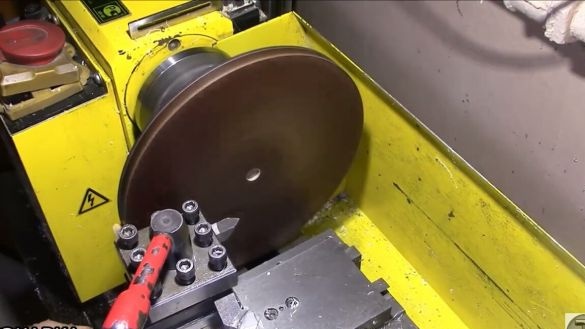

The screwdriver motor must drive the engine piston. To do this, an adapter is made from a fairing on a lathe. After from the channel, fasteners are made for the motor of the screwdriver.

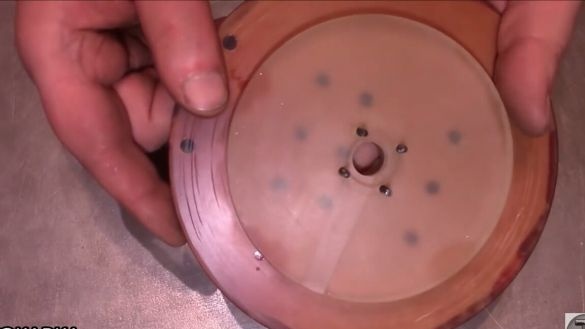

Step 3. Production of the work surface

As a working platform, the author advises using a thick board and org-glass. On a lathe, he gives them the right shape. On org-glass, a channel for chip removal is made with an ordinary chisel. A channel is made on a wooden base in order to conveniently fix the saw. The basics are fastened together with super glue.

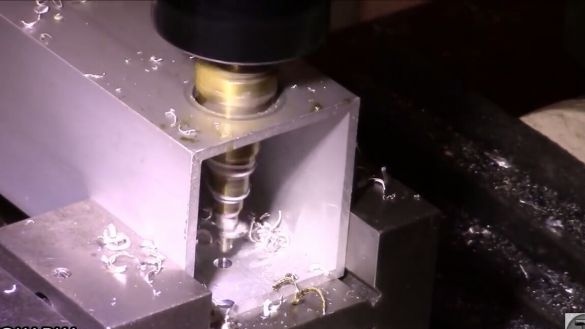

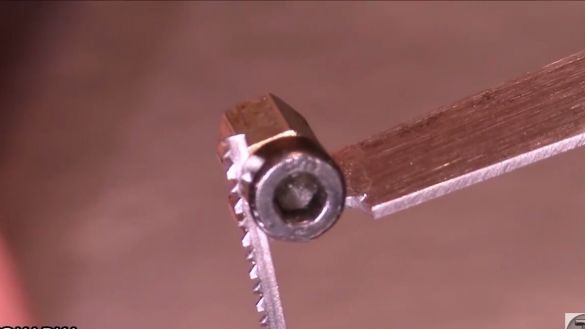

Step 4. Production of fasteners and return mechanism

A fastener made of a steel rod on a lathe is mounted to the piston using solder. A plate is cut off from the old saw as a return spring.Then, after processing a piece of profile and a fastener on a milling machine, he makes fasteners for this plate. A flux-treated, elongated nut is attached to the plate

Step 5. Final touches

The design turned out brutal. At the first test, the machine tried to run away on the table due to strong vibration. Therefore, the author recommends attaching a clamp or a metal part from a vice. It is also recommended that a rubber plate be attached so that the machine does not slip. The author tried various power sources, but the computer power supply turned out to be the best option. It turned out to be an excellent machine, since a cutting element with such an engine is capable of doing miracles by working with completely different materials, such as glass, wood, etc. Thanks for watching, we like.