Materials:

1. Ordinary vice

2. 50-tk corner

3. Bolts and nuts

4. Paint

Instruments:

1. Bulgarian

2. Drill

3. Drills

4. Welding machine

5. Iron brush on the grinder

Step 1: Restoration

At this stage, the author removes rust from the old vice and from the corners. Then the vice is painted. It may not be restored, but it will be better to work with such a vice and it will be pleasant to the eye. You decide.

Step 2: making the swing mechanism

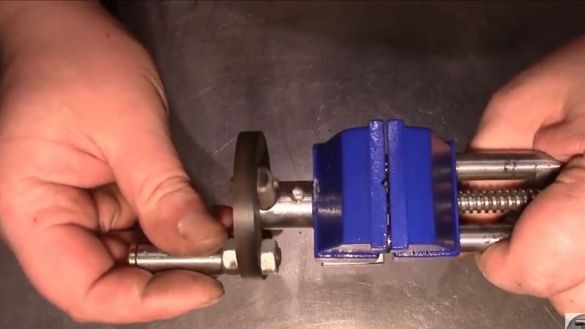

A digital bar at the corner marks three segments of 4 cm. Then it is cut off by a grinder. Before cutting, it is better to polish the corner. Two corners becomes one with welding. Holes are drilled on all three parts (seen in the photo). M8 thread is cut into the holes. Then a piece of a 10 mm metal plate is cut off, an M8 bolt is welded to it for fixing the corner and four holes for screws for fixing the vice. The plate will provide a more reliable connection. It looks so that nothing sticks out of the plate, its surfaces should be smooth. We connect all the parts.

Step 3: final touches

The author finds the flywheel in the old trash and uses it as a handle to tighten the vise. Also, from a bolt and a plastic handle found in the trash, he comes up with fasteners for a clamp. Finally, the author demonstrates the work of this vice, as we see in the video. The vice can rotate around the axis, which is very convenient in the process of processing the material.They also provide safety, for example: holding a regular piece of metal for cutting or grinding, the entire stream of sparks will fly at you, and by making the necessary slope you will avoid injuries. If you liked the article, then like it. Thank you for watching.