This article will be useful for anyone interested in unusual items for design. In it, the author of the ZH Fabrications channel will show how he made an exclusive chair with adjustable seat height.

Materials

- steel plate

- Stainless steel profile pipe

- Impregnation for wood

- Sheet steel

- A hairpin with a diameter of about 30 mm, a nut to it.

Instruments, used by the author.

- Orbital sander

- Lathe

- Cutters for a lathe

- Drilling machine, metal crowns

- Band-saw

- Bulgarian with disks

- Welding machine

- Belt sander

- Screwdriver

- clamps

- Chisels

- Corner magnets

- Submersible Saw

- Roller tube for glue.

Manufacturing process.

These were the boards by the author.

Begins the cone manufacturing phase. To do this, dissolves the boards into rectangular bars in section.

The bars themselves are cut on a trapeze.

And already from trapeziums he will make such rings of different diameters.

Using the guide, he puts all the sticks in a row on the masking tape. Then, having missed with glue, twists into a ring.

For high-quality gluing, tightens the ring from the outside with a tape clamp.

Repeats this procedure for other rings.

Here is a set turned out.

On an orbital sander he processes planes.

Then, setting the table at the right angle, grinds the outer edges.

The outer edge of the cone has already become less stepped.

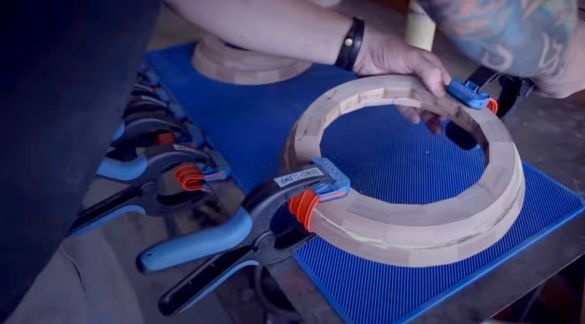

Starts gluing rings together. To begin with - in pairs, clamping with clamps.

Then it collects the entire "pyramid" and glues all the pairs already.

To process a cone blank on a lathe, you need to make a base. To do this, the author first marks and cuts a square out of plywood.

Having found the center on it, it smears with glue and sticks sheets of paper. Then, once again smearing the paper with glue, presses the cone.

After the glue dries, it cuts off the excess with a band saw.

Then it is trimmed on a grinding machine and screwed on the flange.

Sets the workpiece on a lathe, clamps the tailstock. It processes with cutters and polishes with sandpaper.

Now it is possible to process by impregnation.

He removes the flange and tears off the plywood, which is why the layer of paper was needed.

The cone is ready.

Now you can cut out the upper part of the future chair - a plate.

Standard processing of the finished plate - from a coarse petal disc and grinder to polishing.

Having marked the center of the disk, he drills a hole with a crown. Then he processes the sharp edges with a file.

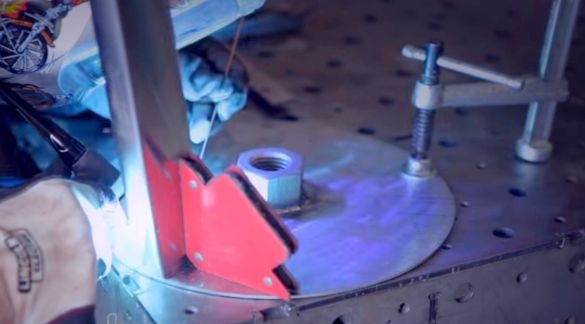

Fixes a clamp to the table, threaded stud with nut and welds the nut to the disk.

A band saw cuts the workpieces for the legs, at a slight angle.

Sets the same angle on the grinding machine, and holding all three legs with a clamp, grinds the ends.

Cleans and polishes the workpiece legs.

From the steel sheet cuts out small rectangles and covers the bottom of the legs, brewing a plate.

Fixes the legs to the disk with welding magnets and welds them.

Three parts are cut from the same profile pipe, they will strengthen the structure. Welds them.

So, the chair frame is ready, now you need to fit the cone to it.

Cuts small grooves for legs in a cone.

Marks, drills and countersinks holes for self-tapping screws.

Screws the cone with screws to the frame disk.

It remains a little to make the seat itself. Prepares materials, drives wood through the thicknesser.

Marks blanks, makes grooves for dowels with an end milling cutter. Installs dowels, greases with glue and clamps with clamps.

While the workpiece is glued, it cuts another disk from the steel plate.

Drills holes for screws and welds a stud to the disk.

Trying on a seat blank to a chair.

Cut a groove for a disk, fastens it on self-tapping screws.

Marks the seat, cuts the edges on the band saw.

The final stage is a little drill in the center of the seat with a Forstner drill. And makes the lenticular selection a rough disk. It removes the chamfer from the edges with a milling cutter. Then polishes the entire workpiece.

It impregnates with oil, a beautiful texture immediately appears. Polishes the legs.

Everything, screwing the seat into place and the chair is ready! The height of the chair can be adjusted by turning the seat.

Thanks to the author for an interesting design decision!

All inspiration!