Good day to all.

For this homemade the author took a steel rack. (Can be replaced with a thick-walled tube or stud with a through hole.)

60 mm long.

And with a diameter of about 6 mm. At the ends of the rack there are threaded holes.

The master will make a through hole in the rack with a 1.8 mm drill.

Like this.

Also, to adjust the oil, the author will use such a crane.

Such a tap is used to supply CO2 to the aquarium.

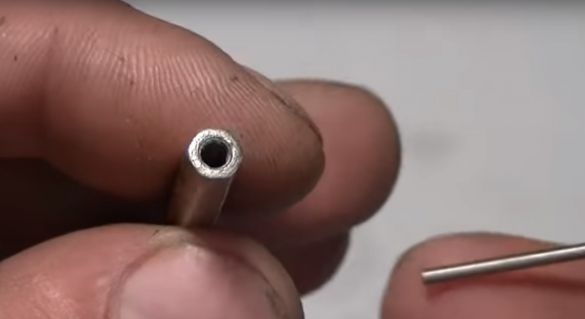

The internal diameter of the nozzle on the tap is 3.3 mm, and the external 4.4 mm.

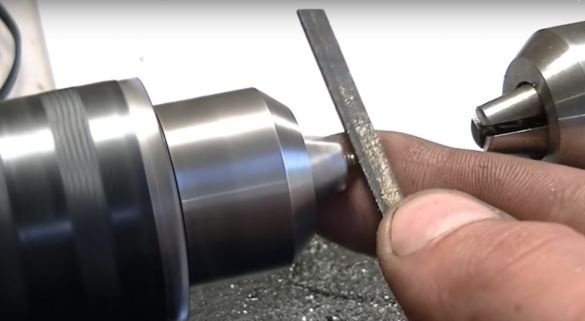

The master cuts the thread M 4, in the outlet pipe to the middle.

The master uses the M 4 bolt as a finishing tap.

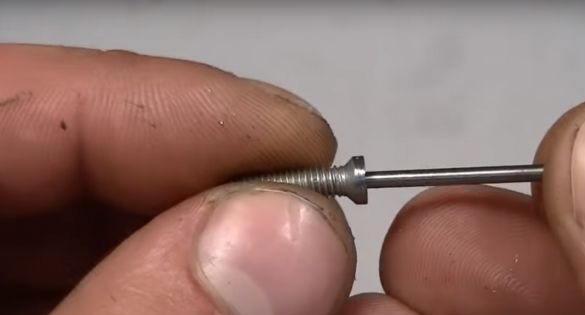

Next, the author needs a hairpin with a length of 20 mm. He will make it out of a bolt.

Cutting off his hat.

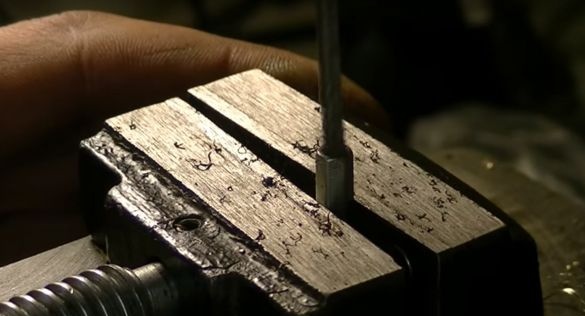

Then the master, installed the finished stud in an elongated nut and clamped it in a vise.

A 7 mm drill finds the center of the stud.

And then it makes a through hole with a 4.2 mm drill.

Next, thread M 5.

Then the author took the M 4 screw.

In which he needs to make a hole with a 1.8 mm drill.

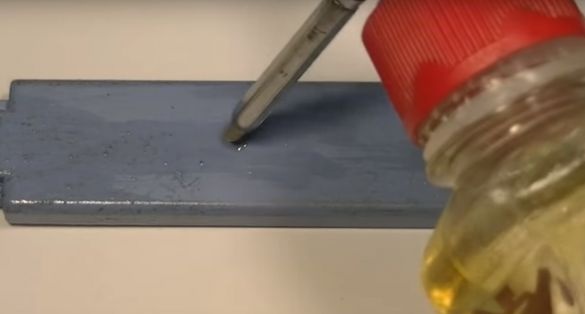

For this, the master will make a simple adapt. Take a square and make a 1.8 mm through hole in it, and increase the hole to half the square and cut the M 4 thread.

Install the screw in the threaded part, and through the return hole in the square will make a hole in the screw.

After that, the master will increase the hole in the rack to 3 mm.

And cuts the thread.

After installs the screw.

The author will do the same procedure with one more screw.

Next, the second screw with a hole, the author will install a drill in the chuck and with the help of a needle file off one edge of the screw under the cone.

After the finished part, the author will install on the other side of the rack.

The master shortened the rack a little and cut the M 4 thread.

After the author took a wide washer.

And fixing it on a wooden surface, I drilled a hole up to 8 mm.

The author made two such details.

Then the master moved on to the aesthetic part of homemade work. To do this, he took a drawing made on glossy paper.

And not a big piece of copper foil.

And he prepared an etching solution. The composition of the solution: hydrogen peroxide 50 ml., Table salt 2 tsp, citric acid 3 tsp.

Next, the master immerses the foil in the solution not for long, to remove all contaminants.

After foil and drawing, the author placed between the sheets of an old book.

And it went well with an iron.

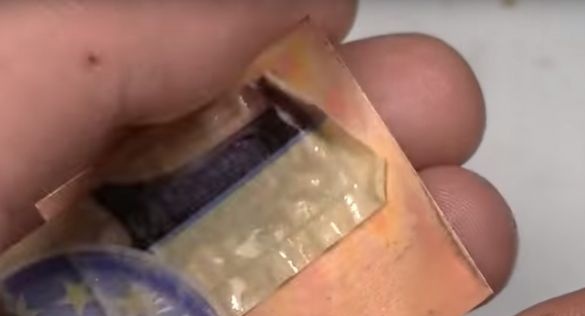

Then, soaking the paper with water, removed it.

And cutting off everything unnecessary.

Immersed the foil in the etching solution.

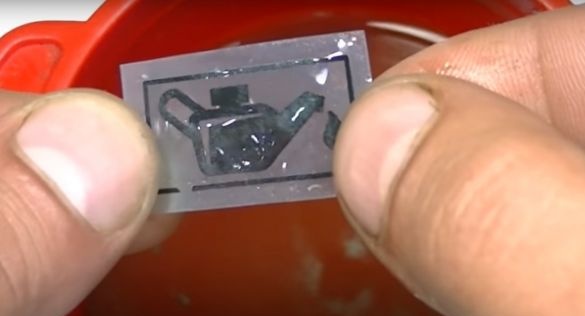

After etching.

The master will stick the foil to a suitable sized plastic bottle.

By spraying the back of the foil.

After the master proceeded to polishing. Sandpaper.

Then paste toothpaste.

Next, apply beaten egg protein. (The protein acts as a protective film of the copper surface from darkening.)

And after drying the protein, varnishes.

When all the parts were ready, the master set about assembling.

For all threaded connections, the master did the winding of the FUM tape.

Rack connected to the crane.

After I installed a stud with a nut.

Next is the puck.

Then the cork.

The rubber washer followed by the second metal washer. 66

And this whole sandwich was clamped with a nut.

He put a cap on the bottle.

And a protective cap.

So it's time for the test.

A drop of oil on an open tap.

The second position of the crane.

And the third position of the crane.

Such a tool in the end turned out to be the master of our today's article.

That's all, thank you all and see you soon!

Video