Greetings to all lovers of making something out of nothing !!!

I got into the hands of an interesting tool. It is not clear what the master wanted to portray but there is a suspicion that this is a machete in the style of Hai Tak. Let's try to make something less exotic but more useful out of it.

Steel seems to be quite good, and the shape of the forging asks to be made from it.

Tools needed and fixtures.

1. Welding inverter.

2. Angle grinder.

3. Electric drill.

4. The drill.

5. Sharpening machine.

6. Power supply 12 v.

7. Hacksaw for metal.

8. Needle files.

9. Vise.

10. Tap.

11. Drills.

12. Caliper.

13. Marker

14. Awl.

15. The donkey.

Materials and consumables needed.

1. Hairpin M 8.

2. Nut M 8.

3. Brass rod Ø 50 mm.

4. Ebonite.

5. Cutting plastics and heavy rubber.

6. Epoxy resin.

7. Sandpaper.

8. Pasta GOI.

9. The salt.

10. Cutting and flap wheel on angle grinder.

1. Making a blade.

Unfortunately, the former master, in an attempt to make a pen, drilled unnecessary holes. You have to trim and weld a stud for the handle. The design of course will turn out less reliable but for a kitchen knife is quite acceptable.

To begin with, they drew an approximate shape of the blade on paper, glued to the workpiece and cut it out with a grinder, not forgetting to periodically cool it with water.

The final refinement of the form produced on the grinding machine.

We cleaned the blade with a petal circle.

The descent from the butt made on the grinder.

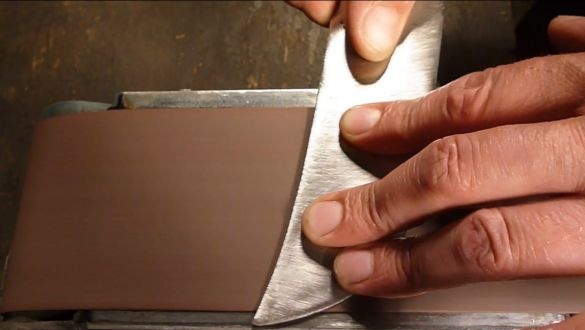

Large scratches were removed with a donkey and cleaned with sandpaper from 120 to 280.

As a result, we got such a blade.

Unfortunately, some traces of the forging could not be removed and we decided to hide them with an inscription.

To do this, degrease the blade well and cover it with paint.

Scratched the inscription with an awl.

Put cotton wool soaked in the most concentrated salt solution on top.

The plus wire 12 v of the power supply is connected to the blade and minus to the electrode. Etching the inscription took about half an hour.

The blade was polished on a felt circle using GOI paste.

2. The manufacture of gulband.

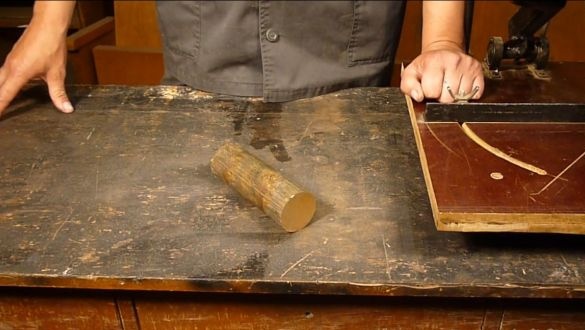

Gulband decided to make brass, just in the workshop a suitable bar was littered.

Cut off from him 1.5 cm and cut from three sides.

Corrected on the grinding machine.

In the center marked the slot for the blade. To do this, they painted a brass marker and using a vernier caliper drew a strip.

The slot was made a grinder.

The hole for the blade shank was drilled with a drill of a slightly smaller diameter and then fitted with a file that was clamped in a drill.

The final fit of the gulband to the blade was made with a drill and needle files.

To make the gulband near the blade thinner, they cut about 4 mm on each side.

Also cut the bottom corner.

The final form was given on the grinding machine, then with files and sandpaper.

3. The manufacture of the handle.

For the base of the handle, a piece of hairpin M 8 was welded to the blade. Asbestos was used to not spoil the polishing.

The welding seam was smoothed out on a grinding machine.

The handle itself was made of ebonite with inserts of plastic and thick rubber. Initially, it was supposed to make another insert of fluoroplastic, but as it turned out, the epoxy did not stick to it and I had to abandon this idea.

A piece of ebonite was cut taking into account the inserts and the back and drilled through the hole.

A blind hole was drilled in the back plate and a thread was cut in it.

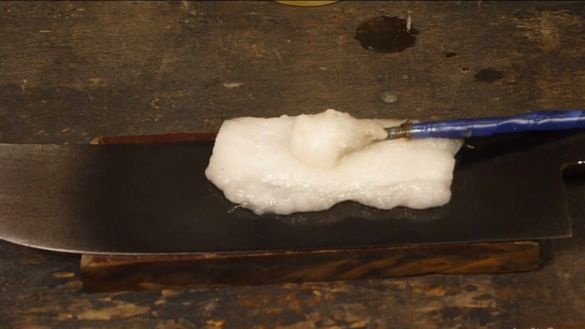

Gathered the handle parts together, carefully coating each layer with epoxy, and fixed with a nut.

The oiler was oiled with resin and tightened on the thread.

After the epoxy hardened, they cut off all the excess with a hacksaw for metal and gave the shape of a handle on a grinding machine.

We cleaned it with sandpaper and polished it on a felt circle.

The result was a good kitchen knife. It copes with meat especially well.

All good and good luck in work !!!

You can watch a video about making a poke here.