Carried away by wood carving, the Master realized that he needed a desktop. The table must meet the following requirements: dust collection, a place to store tools and material, a screen for photographing products, lighting, the ability to move the table. After thinking a little, the master decided to remake the sewing table to fit his tasks.

Tools and materials:

-Sewing table;

-Boards;

-Screwdriver;

- Joiner's glue;

-Fasteners;

-Hacksaw;

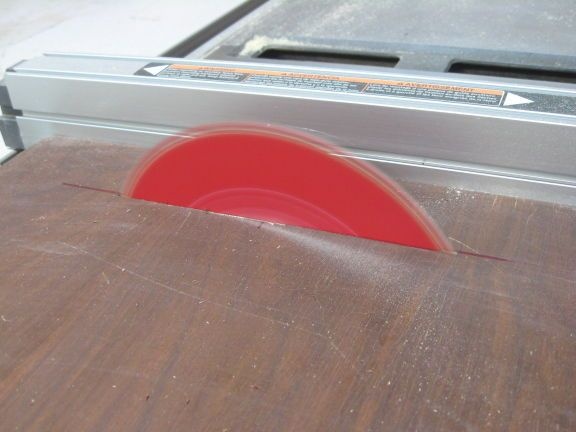

-A circular saw;

- Clamps;

Milling cutter;

-Acrylic;

- chipboard laminated;

-Plastic pipe;

-Bandsaw machine;

-Dust collector socket;

-Vise;

-Metal plate;

-Hammer;

-Paint;

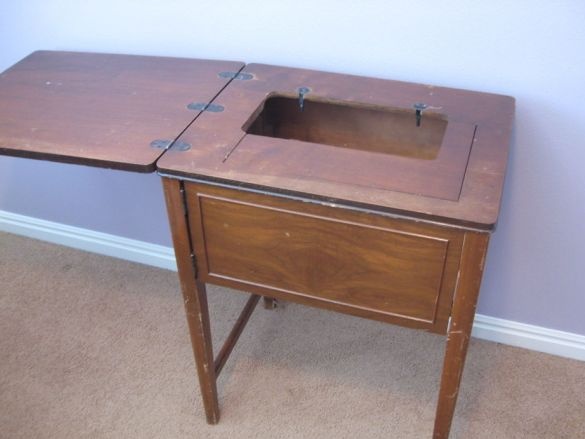

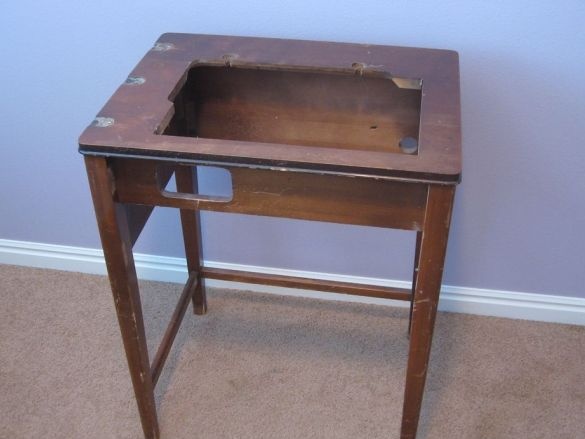

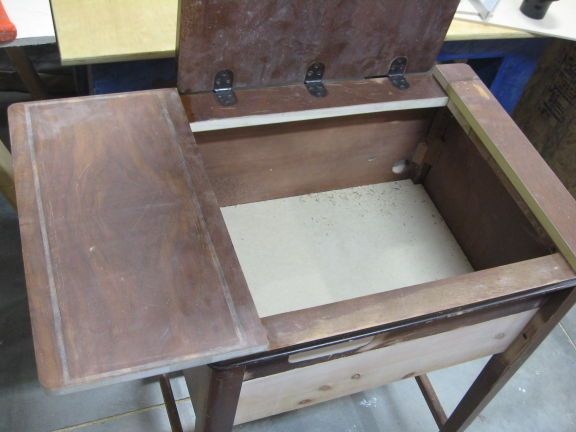

Step One: Disassembly

Disassembles a sewing machine, a hinged lid and a middle opening table section. Removes loops.

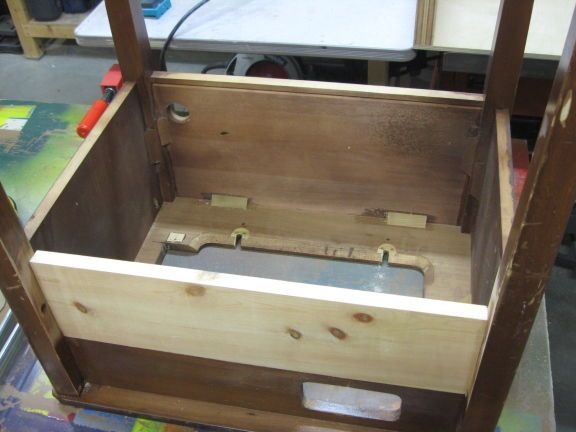

Step Two: Storage Box

From the compartment for storing the sewing machine makes a box.

Cuts the top of the drawer.

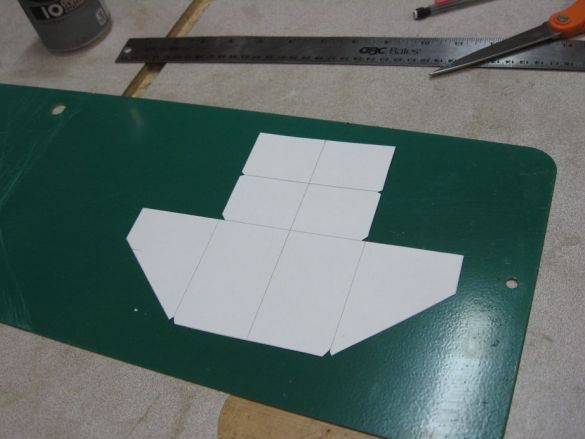

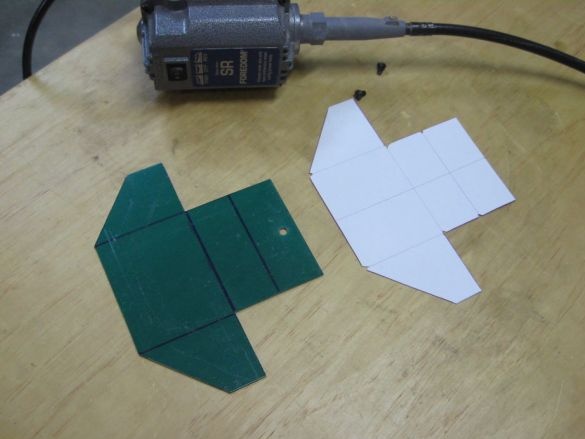

Step Three: Cover

Redo the hinged lid. Makes a slot for the dust collector slot.

On the table carves nests for loops.

Installs the cover.

Step Four: Protective Shield

From acrylic makes and installs a protective shield.

Step Five: Screen

Of the bars makes a frame. Laminated chipboard is attached to the frame. The engraver engine will also be mounted on the frame.

Step Six: Engraver

For the holder, the master makes and fixes the bracket from a plastic pipe.

For the engine mount is made of a metal plate.

Seventh step: port for a dust collector

Makes and fixes a dust collector port. The port will be connected by a hose to a previously built cyclone.

Step Eight: Cover

Covers the table. The port is black.

The desktop is ready. It remains to install the lighting, connect the dust collector hose and you can get to work.