In this tip, YouTube author Samodelki Vitmana tells you how he made a sandblasting nozzle from an old spark plug.

Materials

- candle

- Steel round timber.

Instruments, used by the author.

- Bulgarian

- Gas-burner

- Disks for metal

- Diamond blade for ceramics

- Grinder

- Vise

- Pliers.

Manufacturing process.

First, the author made a nozzle for a sandblasting machine, having found a drawing on the Internet.

He also changed the size of the nozzle to the performance of his compressor. The inner diameter of the hole was 3 mm. The author machined it from 40X steel and hardened it by heating to a temperature of 760 ° C, and then cooling it in water. Unfortunately, the nozzle did not want to work, the hose was blocked by sand.

Therefore, the author decided to use the ceramic part from the car spark plug. The inner diameter of the nozzle was 4 mm.

First of all, the author pulls out the contact rod. To do this, he evenly heats the candle with a gas burner, and the rod itself comes out a little.

Then he pulls out the rod with pliers.

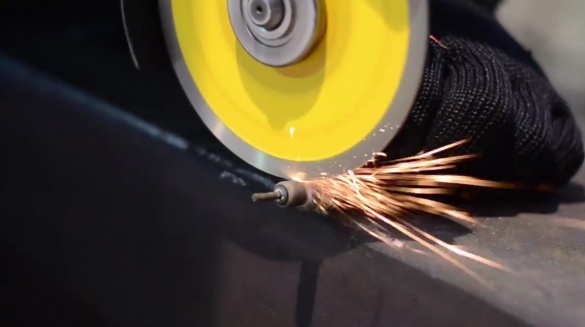

Then grinds the rolled edge on the candle body using a grinder.

Next, a ceramic insulator is knocked out of the candle body.

It cuts the edges of the nut on the sharpener and gets rid of it.

Using a diamond wheel, she cuts off part of the ceramic insulator with a central electrode.

On a lathe, the author has carved here such an adapter with a clamping nut. Link to drawing.

As a result, the author obtained a simple nozzle for a sandblasting apparatus.

Thanks to the author for the idea!

Good luck to all!