In this article, the author of YouTube channel "Random Hands" will tell you how he made a melting furnace from an empty cylinder from freon.

Materials

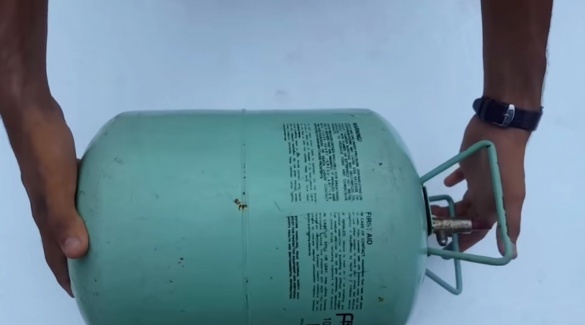

- Freon cylinder

- Gypsum

- steel strip

- A piece of steel pipe

- air blower

- Furniture hinge

- Plastic bucket

- Aerosol heat-resistant paint.

Instruments, used by the author.

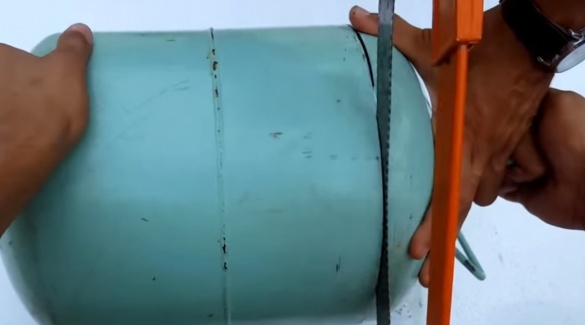

- Hacksaw

- Welding machine

- Anvil, hammer

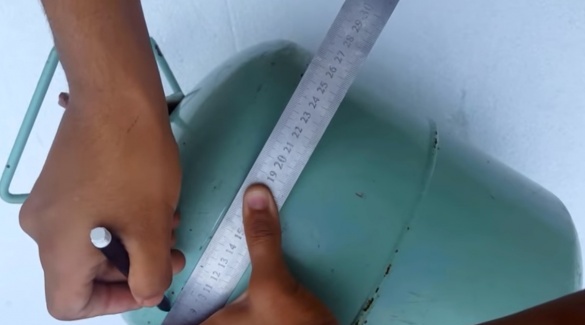

- Ruler, compass, marker

- Watering can, mittens, bucket.

Manufacturing process.

To begin with, the author marks a line around the top of the container, and cuts it off with a hacksaw. Be careful, this is an inert freon cylinder. Make sure that there is no pressure in the cylinder. Freon is not explosive and does not ignite at any temperature. If you decide to cut a propane cylinder, follow the safety rules, because even a small amount of it will catch fire from a spark!

Further, with the help of a compass, the author marked a hole for blowing in the lower half of the body.

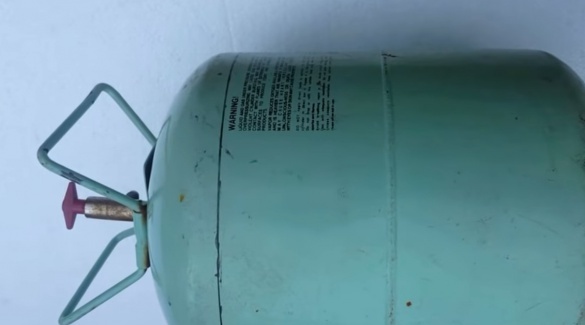

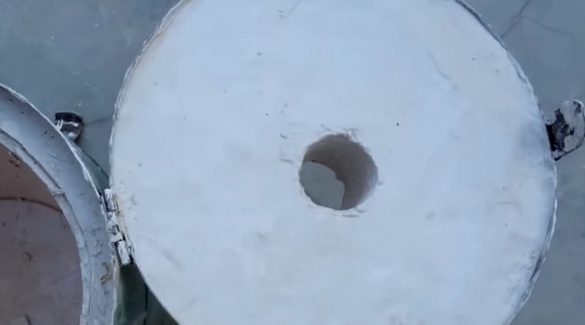

And the exhaust hole is in the upper part of the cover, around the valve.

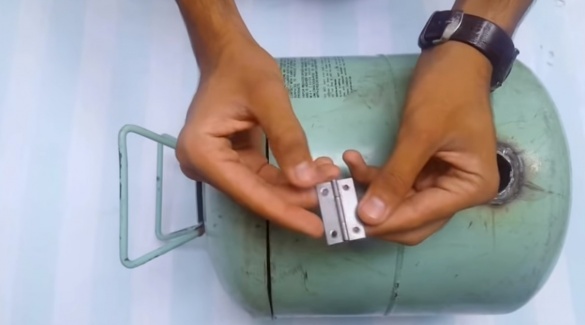

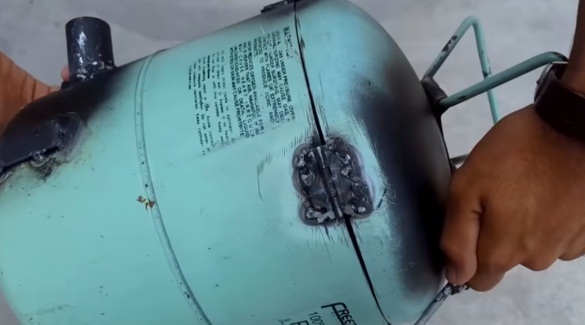

Then, cutting out the holes with a gas cutter, he tries on an eyelet for the lid.

From the steel strip bends three legs, and welds them to the body.

I also welded the blowing pipe at a slight angle, and an eyelet with side cover stoppers.

In addition, a latch lock was made of a bolt and a piece of steel bar.

The next step, in a normal bucket, spreads gypsum with water in a ratio of 2: 1.

Then, having installed an unnecessary bucket inside the furnace body, it pours the solution into the gap between them using a wide-necked watering can. The bucket will need to be held for 5 minutes until the plaster sets.

After the solution has solidified (the author did not guess to lubricate the bucket with a separator), the bucket will have to be broken and discarded. The oven lid is also filled.

Cleans the blower hole, pay attention to the angle at which air will be supplied.

Everything is ready, it paints the furnace body with heat-resistant spray paint, shaking it thoroughly.

Installs an air blower, he made this impeller separately. You can also connect a conventional Soviet blowing vacuum cleaner.

Further, he puts the crucible in its place and fills the space around it with coal.

It ignites coal with a gas burner, turns on blowing, and fills the crucible with unnecessary aluminum parts.

The stove has not warmed up enough. For melting aluminum, a temperature of about 700 degrees is needed.

The crucible is hot to crimson, the aluminum has melted. The author throws out the slag.

He takes out a crucible from the furnace and pours liquid aluminum into water. It turns out beautiful ingots.

Thanks to the author for a simple idea for making a melting furnace!

Good ideas to all!