Greetings to all lovers of crafting something from nothing.

Smoking is definitely harmful. and nowadays it’s also expensive. The plans, of course, have a desire to get rid of this bad habit, but for now try to at least reduce its cost. We got mahry varieties of Virginia of medium strength and a package of cigarette liners, and since manually stuffing is not at all an option to make a machine.

Tools needed and fixtures.

1. Electric drill

2. Sharpening machine

3. Hacksaw

4. Pliers

5. Vise

6. Side cutters

7. Screwdriver

8. Felt circle

9. Drills

10. Scissors.

Materials and consumables needed.

1. Sheet aluminum

2. Copper tube

3. Plywood

4. The engine from the old Soviet fan

5. Steel wire

6. Bicycle spoke

7. Screws

8. Pasta GOI

9. Sandpaper

10. Screws with nuts

11. The spring.

First, we’ll make a tobacco hopper.

From a sheet of aluminum, cut out a rectangle of arbitrary sizes and clean it. Soft material is well cut with ordinary scissors.

By bending the resulting workpiece we get the base of the hopper.

The end walls will be made of plywood. We mark it, cut it with a hacksaw for metal and process the slices on a grinding machine.

We drill holes for the screws and collect all the parts together.

Next, we take a copper pipe on which a cigarette sleeve is worn. We mark with the thickness of plywood. We polish the marked section of the tube on the felt circle using GOI paste and cut off at an angle of about 45 degrees. Angle is needed for more convenient dressing of the sleeve, polishing is for better gliding.

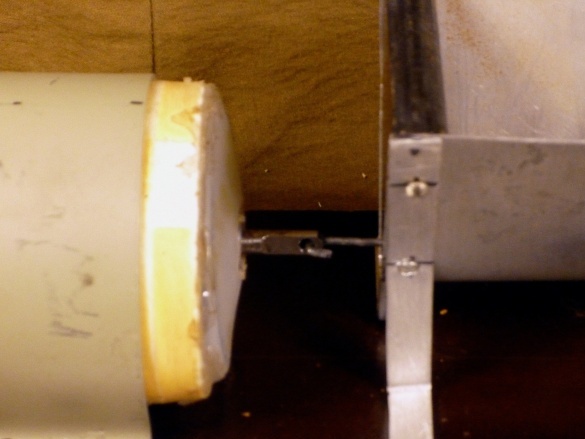

We drill a hole in one end of the hopper and insert a tube into it. In the opposite end, we drill a hole for the shank of the screw. It is desirable to observe the alignment of the holes.

We will make the auger from steel wire. To do this, wrap it around a bicycle spoke and stretch it. If the wire bends poorly, it can be preliminarily annealed.

It is necessary to twist and stretch the auger until it will freely enter the copper tube.

For the engine of our machine we use an engine from an old Soviet fan.

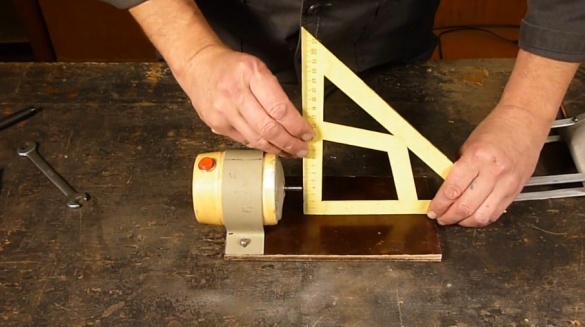

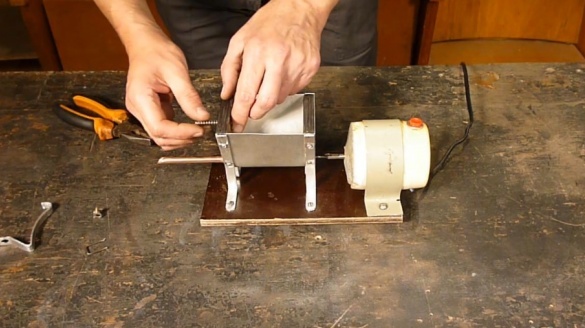

To fix the engine to a plywood bed from a piece of sheet aluminum, bend the clamp.

We drill holes and pull the engine to the frame onto the screws. For ease of use, put the power button on the body. Close the open part with a capron lid. To fix the screw, drill a hole in the motor shaft.

Now you need to combine the engine with the hopper.

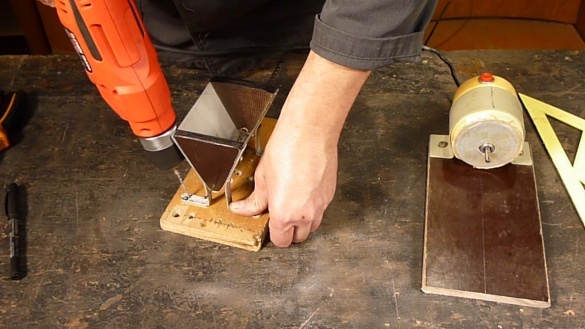

We cut four strips of sheet aluminum, mark it with the holes already in the hopper, drill it and fasten it to the hopper.

We measure the distance from the bed to the center of the motor shaft, measure the same distance from the hole in the hopper and bend the legs.

We insert the auger and if everything converges we cut off the excess, drill holes in the legs and screw the hopper to the bed with screws.

Bite off an extra piece of auger with side cutters.

Pass the shank of the screw into the hole in the motor shaft and bend it. There are no special revolutions or power in this engine, so this kind of mounting method has a place to be.

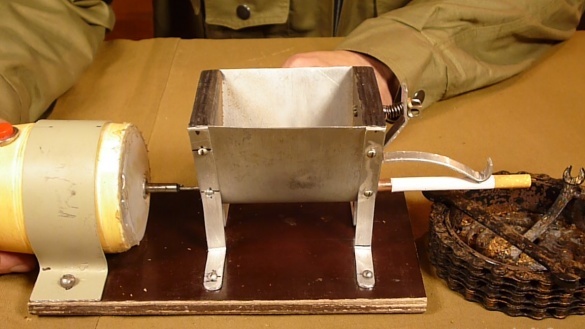

This can be done, but you would have to adjust the density of the cigarette pack by holding the sleeve with your finger. This is not very convenient, we will make a not difficult clip.

To do this, bend the clamping bracket of aluminum and in the end of the hopper, drill three more holes above the copper tube. For screw and mounting bracket.

We tighten the screw in the upper hole and fix it with a nut.

We put a spring on the screw, then a clamping bracket and tighten the nut.

Fasten the clip with a metal bracket. We insert it into the holes and bend from the inside of the hopper.

The result is such a simple structure. Now turning the nut can achieve the desired density of the cigarette pack.

In general, of course, quit smoking and be healthy, good luck in your work.

Video about making a cigarette liner

can be seen here.