This article will be interesting to everyone who works with the router, and he needs to cut or process circles, or parts of a circle. In it, John, the author of YouTube channel "John Heisz - I Build It", will bring to your attention an extremely simple and, at the same time, extremely useful device for cutting a circle using a milling cutter. It is best suited for circles of small radius.

Homemade is so simple that it can be made in 10 minutes (without taking into account the drying of epoxy glue).

Materials

- Wooden block

- Old drill

- Two-component epoxy resin

- Steel stud M6, nuts, washers

Instruments, used by the author.

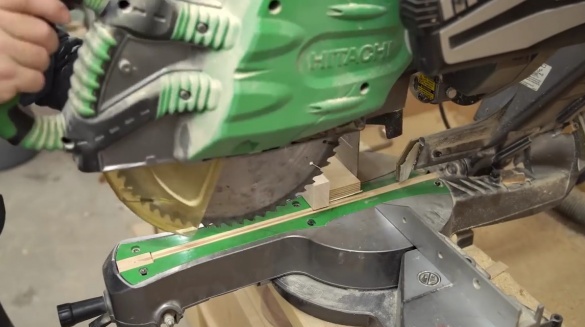

- Miter saw

- Drilling machine

- Screwdriver

- Tap, drill.

The author already had a similar device for a large milling cutter.

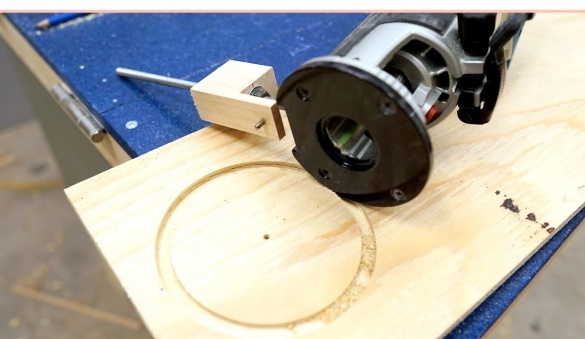

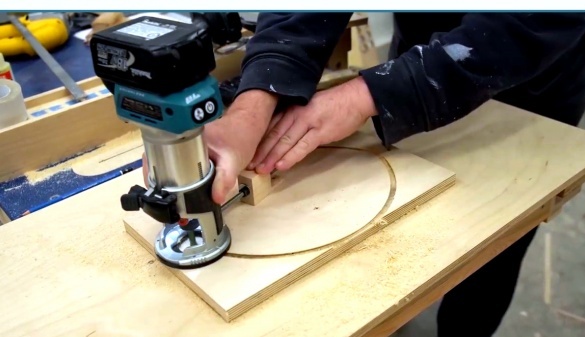

The new device was conceived so that it can be used in conjunction with a small battery milling cutter. If you look at the base of the device, you can see just such a handle, as if intended for some auxiliary nozzles, or devices. Perhaps this pen was originally conceived to create such circles. Be that as it may, this place of attachment is very helpful here.

So, the author twists the lamb and inserts a steel with a thread instead of it, adjusts it to length.

The stud threads and handle mounts are different. Using a screwdriver with a tap, John cuts a new thread. The pin is pressed with a lock nut.

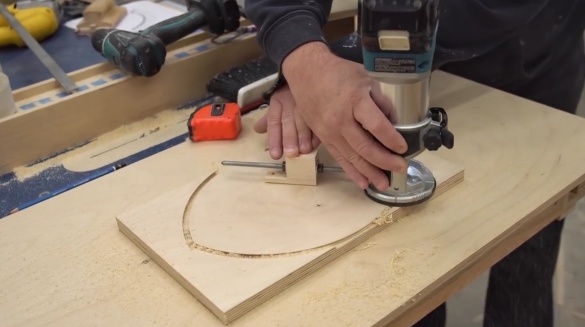

Now the craftsman will need to construct something simple at the other end of the hairpin, which could serve as a fulcrum.

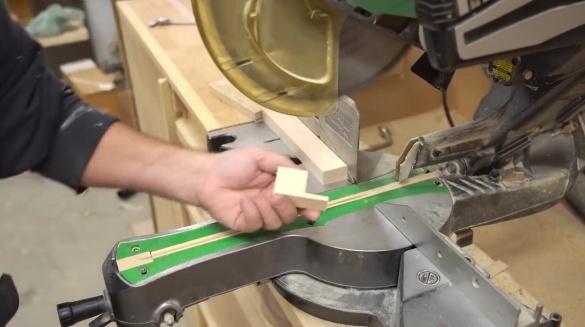

For this purpose, the master will use a piece of hardwood, one edge of which he cuts in this way with a miter saw, after setting the depth of the cut and marking about a quarter of an inch into the cut. He does this simply in a few passes of the saw.

Then he cuts the part along the length and places the resulting wooden figure under the drilling machine.

John drills two holes: one 1/4 inch - for fastening the studs, the second 1/8 inch - for the fulcrum.

As a reference point, he will use a piece of drill. Slices it with a grinder.

Lubricates the hole with a small amount of two-component epoxy, and presses in the cut piece of the drill.

All details are ready, and the author collects the bar.

A bit of testing, everything works fine.

Thanks to the author for an interesting idea for small milling work!

Good ideas to all!