This article will be of interest to everyone who cares about knives and their varieties. In it, John, the author of YouTube channel "John Heisz - I Build It", will present to your attention the process of making a knife from ceramic tiles for the floor.

I must say right away that this is not a simple matter and strongly depends on the selected ceramic tile. Even porcelain tiles can be of very different grain sizes.

Materials

- A piece of ceramic tile of the required size

- capacity with water

Instruments, used by the author.

- Belt sander

- Bulgarian with a diamond disk

- Diamond coated file

- Marker.

Manufacturing process.

So, is it possible to make a knife out of tiles? John suggests that the short answer to this question is yes, you can make a knife from floor tiles. However, it is very difficult to make it sharp enough to cut. But even if you manage to make it sharp enough, the knife edge will not last long because the tile is too fragile. Nevertheless, the author really wanted to do this for quite some time, and today the day has come.

So, he has a piece of tile from the set that lies in his kitchen. This type of tile is known as porcelain tile. It is harder, while ceramic tiles are hard only on the outside, and inside it is soft.

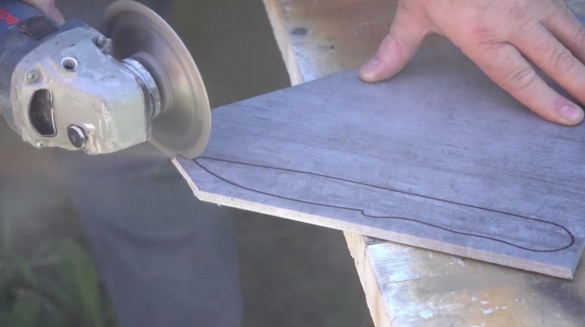

Without hesitation, the author seized a knife in the kitchen to use as a model. He circled it around with a marker.

And then the author began to cut the workpiece using a conventional grinder with a diamond disk, which perfectly cuts stone, tile and concrete. As you can see, the disk produces a rather rough cut; at the corners, parts of the tile break off.

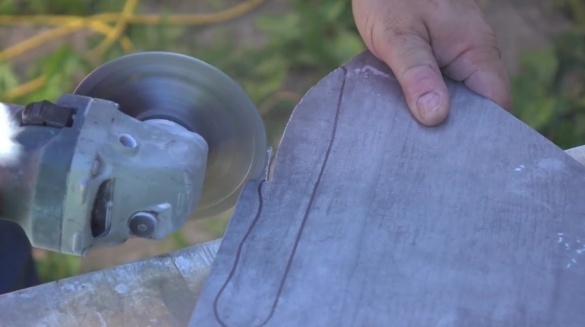

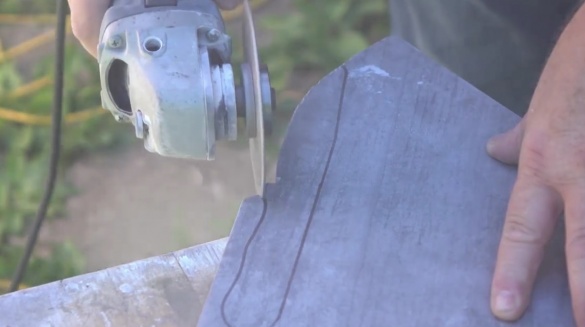

The disk easily removes the tile material from the side. This is the fastest way to make the initial formation of knife slopes, and here you can see that the author takes slopes from both sides, trying to make them thin enough.

So that in the future the author could sharpen the blade with a diamond file.

John tried to sharpen the blade with a file and wet it with water. Moreover, it is impossible to take too narrow, because the edge will be cut too easily and there will be bumps. You can see that the author turned out to be quite a big chip, which may be a problem later, so he changes the strategy.

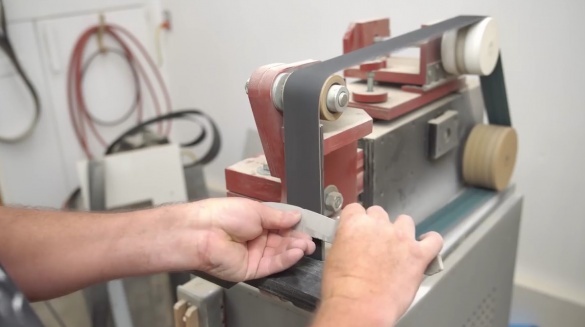

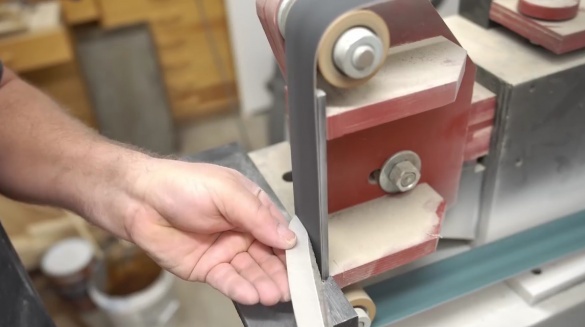

John quickly ran out of patience when working with files, especially since he is a little worn, although it is also used for tiles.The author will try to do the rest of the blade sharpening on his makeshift belt grinding machine, with a tape size of 2X72 inches. He has silicon carbide tapes and they are used to sand glass or tile, and the author used this method before to make a ring of stone, and it really worked well.

But ceramics are much more complicated. It took about twenty minutes to straighten the edges of the blade, descents and remove chips. As a result, the necessary sharpness of the edge of the blade was obtained, although the author was worried that chips would begin again.

This gave John the confidence to work on the rest of the knife. Therefore, it smooths the butt of the knife, back and abdomen of the handle. Also, slightly tilting the edge of the butt and other parts to the surface of the tape, got rid of small chips.

Then the author decided that he would imprison him in the fresh air with a diamond file with water. But as soon as he began to do this, again chips immediately went off. The tool is clearly not suitable for this.

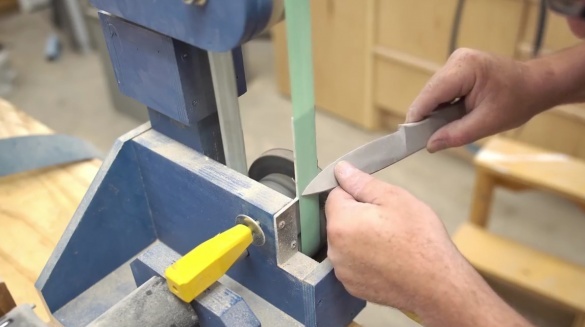

Therefore, the author returned it to the workshop, and chose another grinding machine for further processing of the blade. This is a smaller designer machine with a tape measuring 1X30 inches. And for him there is a very thin diamond ribbon that the author acquired to sharpen tungsten carbide cutters. As you can see, it works very well, the author is really surprised that the sharpening of the blade is obtained.

The author’s opinion is that it is really very difficult to work with ceramics using a file. Everything happens for one simple reason - you automatically work with it like a saw, and with a return movement, chips are obtained. Perhaps you do not adjust the pressure very well. And on the grinding machine, the tape moves in one direction, and the contact area with it is larger.

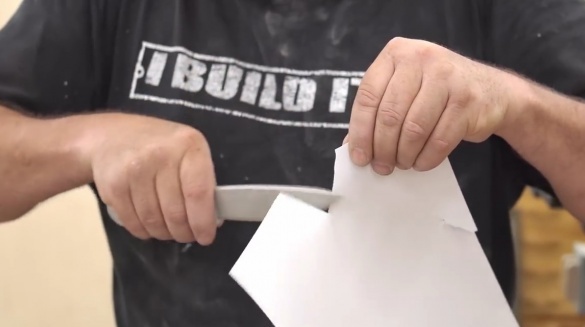

In general, this is the kind of control paper cut that John got.

And so the finished knife looks like. However, the author believes that such knives should not be used for cooking, because the edge is very fragile, and ceramic particles will get into the food.

Thanks to the author for an interesting experiment and description of the technology used.

All the good tools.