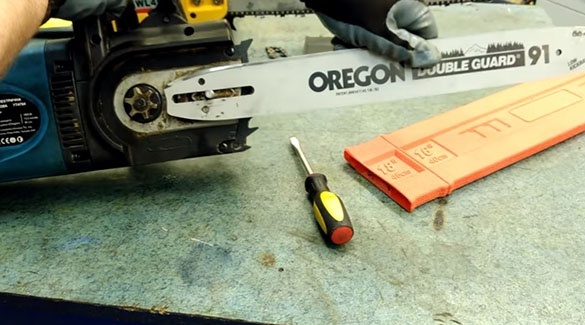

Installation of the tire on an electric saw

At one end of the tire web there is a slot and two holes on either side of it. When installing the tire with a slot, it is put on a special pin on the power saw body, and one of the holes on the pin of the tension mechanism.

The second hole on the canvas serves to transfer lubricant from the oil channel into the groove of the tire.

Chain installation

The chain is pulled over the drive sprocket located on the saw body and the sprocket at the end of the tire. When installing the chain, you must take into account the correct direction of its rotation, which is usually indicated on the product itself.

After installing the chain, the saw’s drive sprocket is covered with a casing, the clamping nut of which is not tightened so that the tire is not completely clamped.

Chain tension

Chain tension control on Chinese electric saws is carried out using a special tension screw, the head of which has a slot for a screwdriver. It is located at the end of the device. For a stronger chain tension, it is rotated clockwise.

The tension screw is rotated until the chain slack disappears. After that, it is manually scrolled on the tire towards the body of the electric saw. This is necessary in order to "straighten" the teeth of the chain in the groove of the tire.

If the chain weakened after scrolling, then it is pulled again.

After that, the tire is taken at its free end, lifted up to the stop, and in this position, the chain slack is eliminated again.

At the last stage, the clamping nut on the casing covering the saw sprocket is completely tightened. In this case, the tire is held in the “raised” position.

A properly stretched chain should be freely pulled out of the grooves of the tire on both sides by about 3-4 mm, and when lowering, lie back in the grooves.

Checking tension after work

When the chain is tensioned, it is possible to finally check the quality of its tension only after a short operational test. For this purpose, several trial cuts are made with it.

Often after trial cuts, the chain on the power saw tire weakens. This happens when its links were contaminated, and during operation these contaminants were dissolved by lubricant.

If this happens, the chain must be tightened again, first loosening the clamping nut on the casing and lifting the free end of the bar up. The power saw, of course, must first be disconnected from the network.

At the end of the chain tension adjustment, it is always checked whether it goes in the right direction without tension, whether it is overtightened. To this end, it is unlocked by pressing the start button, and pushed for the teeth forward with a screwdriver. If she moves a little by inertia, then everything is fine.

And the last one. It is strictly impossible to adjust the tension of the saw chain when it is heated or not lubricated, otherwise there is a risk of it breaking during subsequent operation.

Full video version of the recommendations for pulling the saw chain on a gas and electric saw.