Pipes made of polypropylene make it possible to make plumbing interchanges in an apartment light, flexible and stainless, but people with a creative mindset find such products to use, which has nothing to do with plumbing. Here are a few examples of the witty use of plastic pipe scraps to make fixtures that can always come in handy. home workshop.

Hacksaw Case

A durable and convenient lining on the teeth of a hacksaw can be made from a plastic pipe with a diameter of 20 mm. For this:

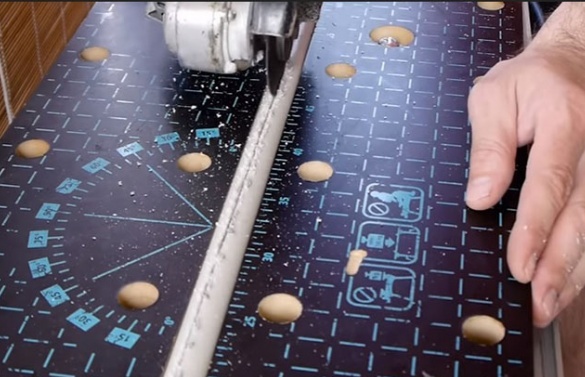

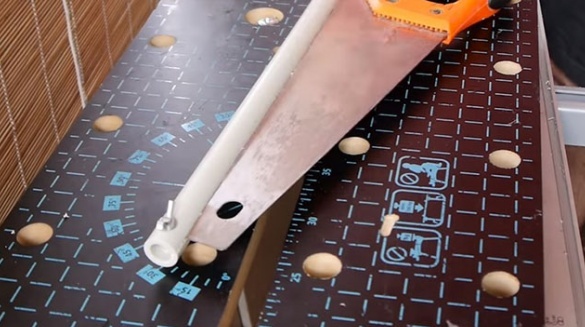

The pipe is clamped in a workbench and, stepping back a little from the edge, make it a longitudinal cut with a grinder, the length of which corresponds to the length of the hacksaw blade. The end of the pipe is left intact.

Cut the cut part of the pipe.

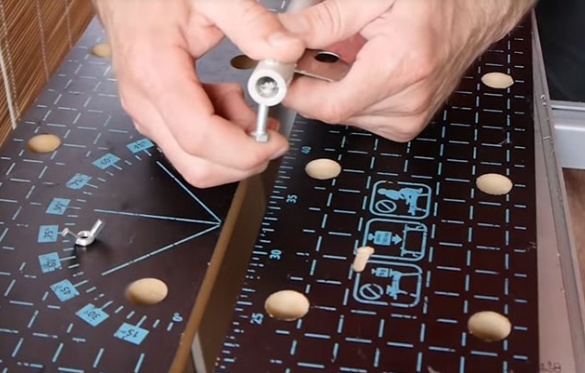

Drilled at the end fixtures a hole with a diameter of 6 mm and insert a bolt into it, onto which a wing nut is screwed.

When the nut is fully tightened, the bolt tightly clamps the pipe and securely fixes the cover on the hacksaw blade, preventing it from moving or flying off from an accidental impact.

Devices for processing curly surfaces

The surface of wooden products to be polished often has concave and convex places, which are very inconvenient for sanding. Simple devices made of polypropylene pipes will help to make such a job more comfortable and faster.

Concave Surface Attachment

In order to do it, you will need:

- a piece of plastic pipe with a diameter of 20 mm;

- a piece of sandpaper with a width equal to the circumference of the trim;

- polyurethane adhesive.

Manufacture homemade happens as follows:

The pipe is sanded.

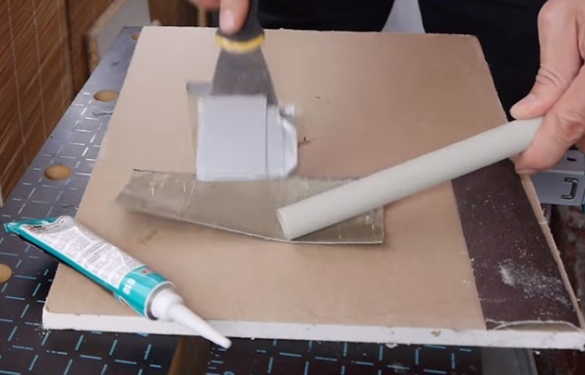

The internal, non-working surface of the sandpaper is moistened and glue is applied to it.

Glue is evened out on paper with a spatula, previously wrapped with paper.

Wrap the pipe with sandpaper.

Coat everything with masking tape.

Two hours later, the paper is removed.

and get a very convenient device for grinding a concave surface

Convex long surface tool

In order to make it, you need all the same as in the case of the first device, only the pipe already needs to be used with a thick, sewer, 32 mm diameter.

Manufacturing process:

The pipe is clamped into a workbench and cut along along from two sides, trying to ensure that the cuts are located strictly opposite each other. The pipe section at the very end is not touched so that the edges of the cut do not clamp the disc of the grinder.

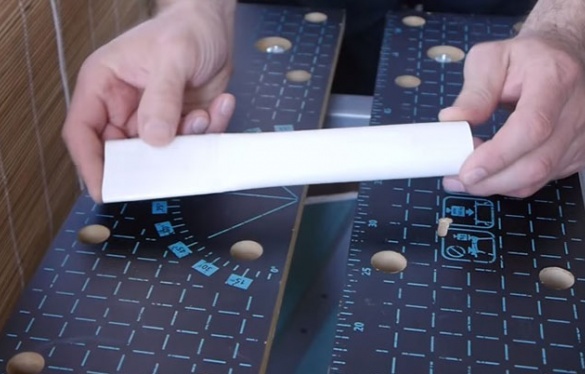

Measure the desired length from the cut end of the pipe, and cut it off.

It turns out two identical halves of the product, which must be cleaned.

Glue is applied to the inside of the sandpaper.

Sandpaper is put in one half of the workpiece, and the second is covered on top.

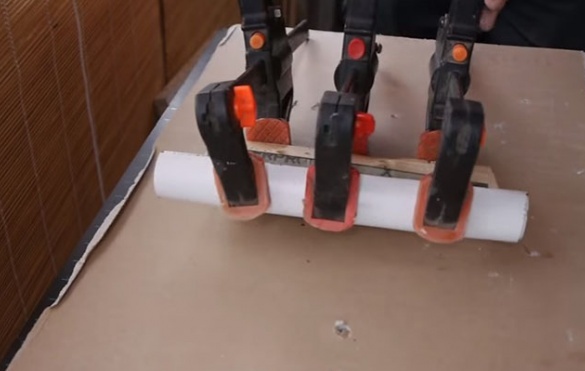

Tighten the entire structure with clamps and leave to dry.

After two hours, the gluing is dismantled and a device is obtained that is very convenient to sand any long round wooden products. It is only necessary to cut off excess sandpaper around the edges.

Chisel Case

Polypropylene is thermoplastic, when plastic pipes are heated, their shape easily changes and, due to this, a variety of useful things can be made from them. To make a cover for a chisel, the pipe is first heated with a construction hairdryer,

and then hands give it the desired shape

The result is a convenient cover for the chisel, a very tightly holding tool.

For ease of use on the cover, you can write the width of the working part of the tool.

Adapters

The property of thermoplasticity of polypropylene can also be used in the manufacture of various adapters from plastic pipes, for example, for blowing a jigsaw. The pipe for this must be selected with a slightly larger diameter than the hole in the tool.

To make the adapter, the pipe is first heated to a sufficiently high temperature, therefore it is recommended to work with gloves on,

then hands narrow its end, insert it into the jigsaw hole and leave it to cool there.

If the connection between the adapter and the jigsaw after cooling the plastic turned out to be weak, then masking tape can be additionally wound on it. In this way, their PVC pipes can form adapters of any diameter and any shape.

Clamps

In order to make a homemade clamp you will need:

- polypropylene coupling with a diameter of 63 mm;

- two threaded rods with a diameter of 8 mm and a length of 20 cm each;

- two heat shrink tubes.

Clamp manufacturing process:

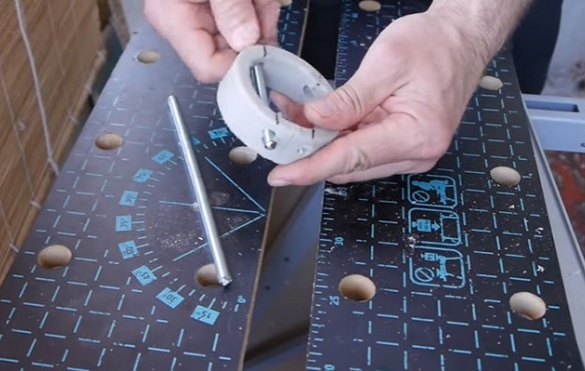

A masking tape is wound around the coupling and cut it lengthwise into two halves. The cutting line is drawn along the border of the application of tapes “painters” on the product.

Cut one of the resulting coupling halves across.

Mark on the workpiece the place of drilling holes for the clamp handles. They should be located away from the main diameter of the coupling, as shown in the photo.

Drill holes in the product, drilling first perpendicular to its surface and only then changing the direction of movement of the drill in the right direction.

Insert the studs in the holes for the clamp handles and fix them with nuts.

Handles bend slightly apart from each other and put heat-shrink tubing on them.

The tool that turned out as a result is very convenient to act when you need to quickly and simultaneously securely grab and hold.

Here are such simple but useful homemade tools can be made from polypropylene pipes. Do not rush to throw them away, if after updating the sanitary wiring in the house you still have extra.

Video version: