This article will be interesting to everyone who works with a drilling or milling machine, both with a movable table and without it. In it, the author of the YouTube channel "TheDacchio" will tell you how to make device for work on drilling or milling machines. This is an inclined vice that will allow you to process the part at the right angle. Whether it is the process of drilling holes, or milling the ends of parts.

Materials

- Steel profile pipes

- steel strip

- Steel bar

- Stud M10

- Bolts, nuts, washers

- Extended nut M10

- Nuts

- Lubricant-cooling spray.

Instruments, used by the author.

- Automatic welding machine

- Band-saw

- Vise

- Bulgarian with a petal stripping disk

- tap

- Drilling machine

- Moving table milling machine

- Clamps, angle, tape measure, vernier caliper, marker.

Manufacturing process.

First of all, the author, having lubricated a workpiece from a profile pipe, cuts it into parts of the right size with a band saw. This can be done on the miter saw, and just a grinder.

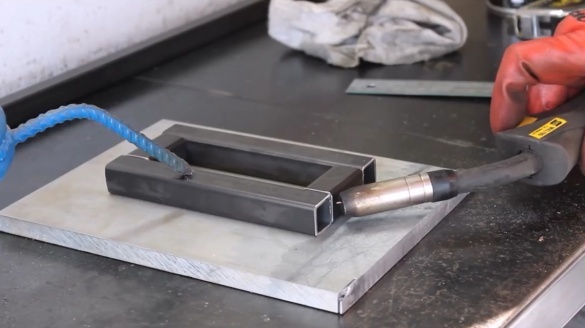

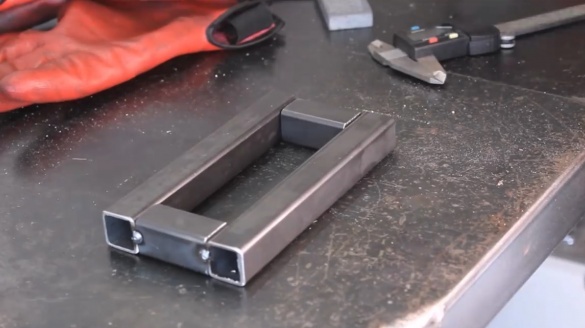

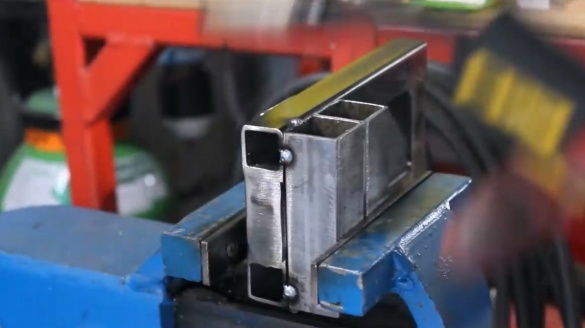

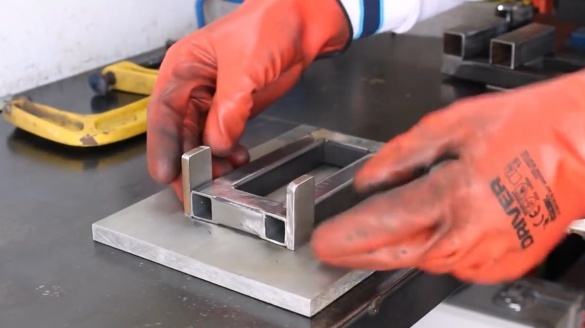

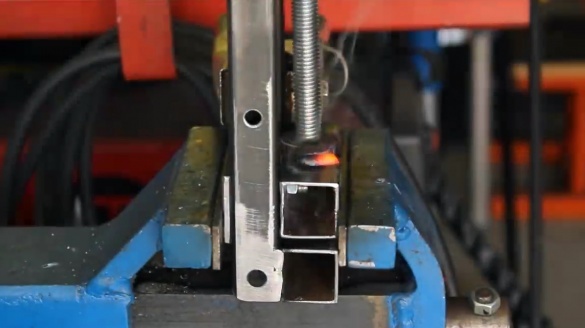

Then it assembles the vise base structure and seizes it by welding at several points.

From the fact that the author's welding with argon blowing - sometimes smoke comes from the profile pipe. Checks the geometry of the workpiece using a corner.

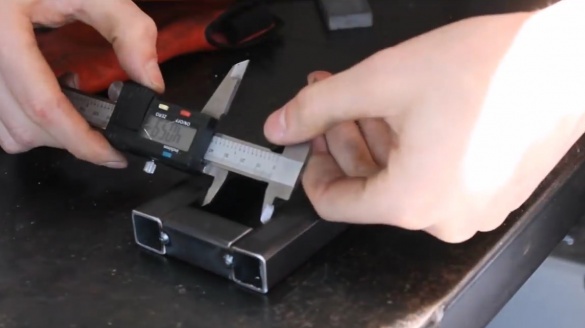

Then it measures the internal distance with a caliper, and boils the seams.

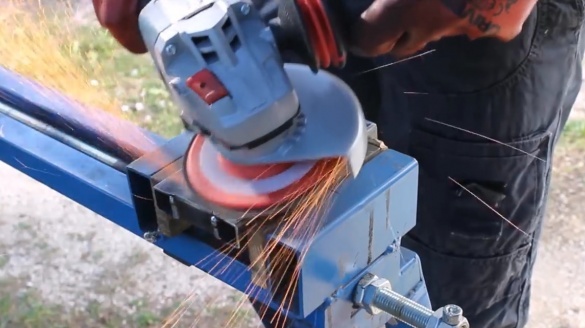

Further, using the flap disc and grinder, it cleans the bumps of the seams.

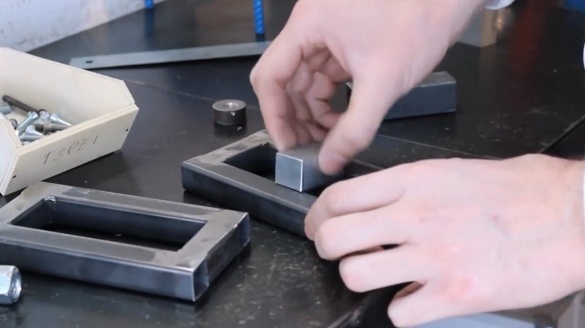

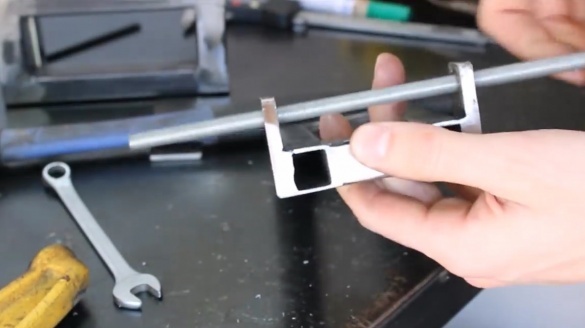

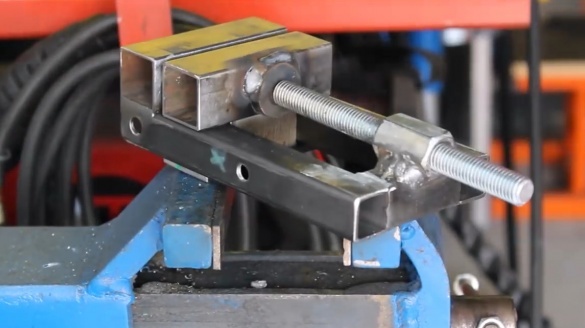

Trying on such a steel bar for the moving part of the vise.

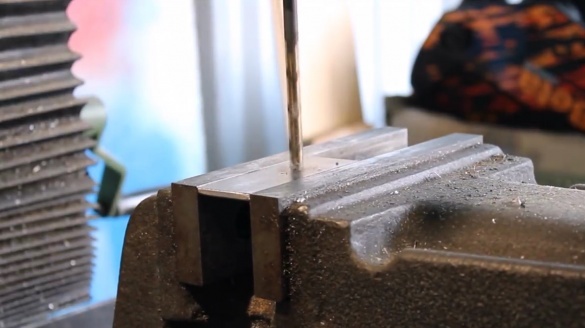

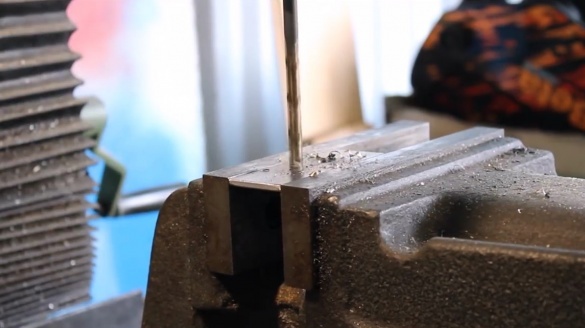

Then he drills two holes for the pressure bolts in the block. It makes the same holes in a piece of steel strip.

The edges of the holes in the strip are countersinked, trying on a bolt head so that it does not protrude.

Screws the bolts through the plate and bar into a section of the profile pipe. She will play the role of a sponge vise.

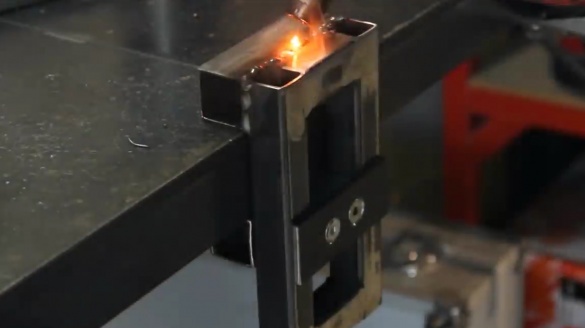

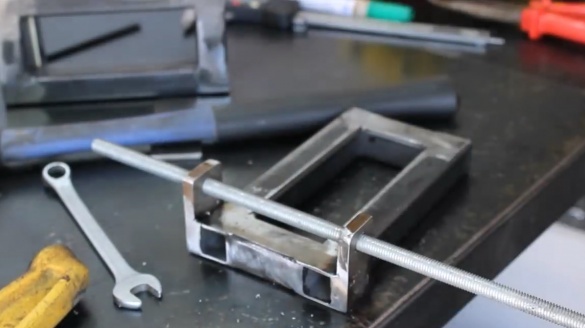

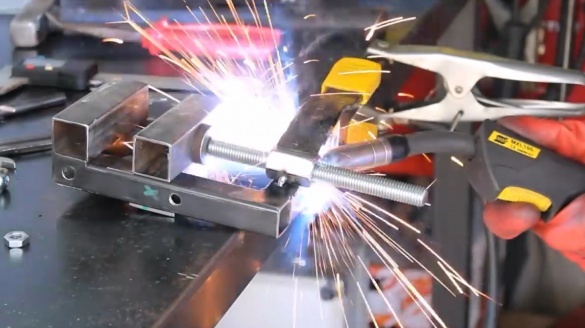

Clamping the base and two jaws in a vice, grabs the immovable sponge by welding.

Then, having checked the fit and geometry, it boils all the seams of the fixed sponge.

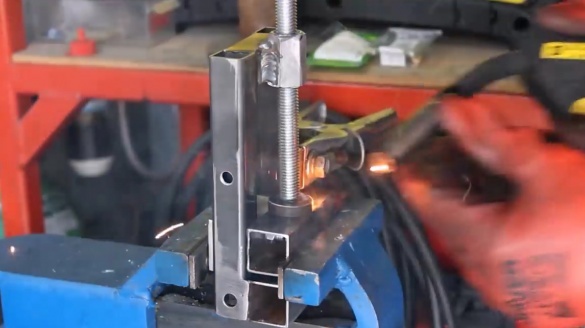

Now the author returns to another, motionless base of the vise. And trying on the "ears" or holders of an inclined base. Grabs them by welding.

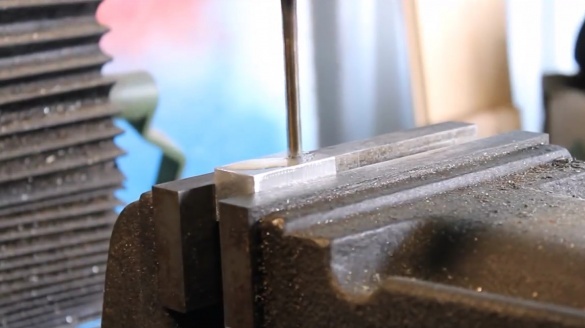

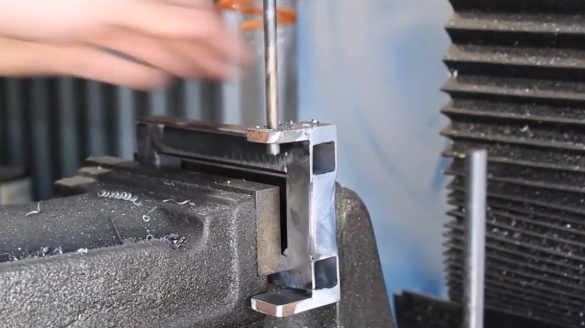

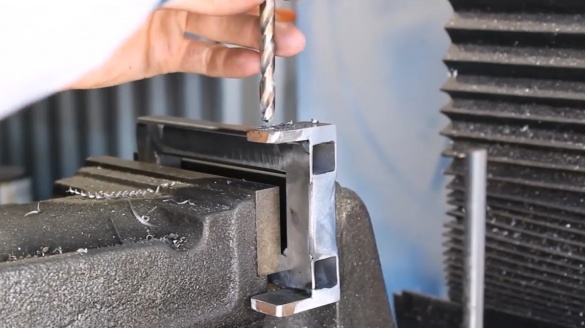

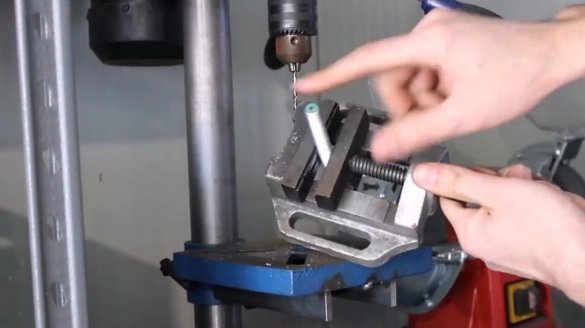

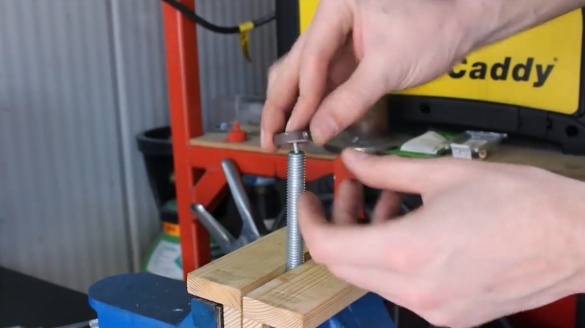

Further, on a drilling machine it makes a through hole in an inclined base, first thin, and then 10 mm drills. Trying on a hairpin.

Now the mate in the ears. Here, in order to avoid bias, he drills a hole in one ear with a thin drill, and only then both of them pass thick at once.

Countersinks the edges of the holes and inserts a hairpin. The base is ready.

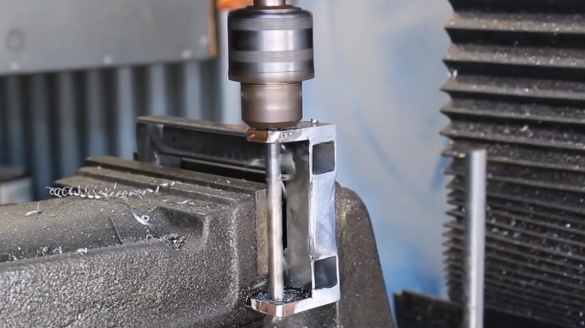

From a steel strip, using a movable table, it makes a guide - a latch, milling a long hole.

Having temporarily collected two bases, checks their inclination, marks the holes for the fixing bolts.

By setting the position of the table, it drills holes.

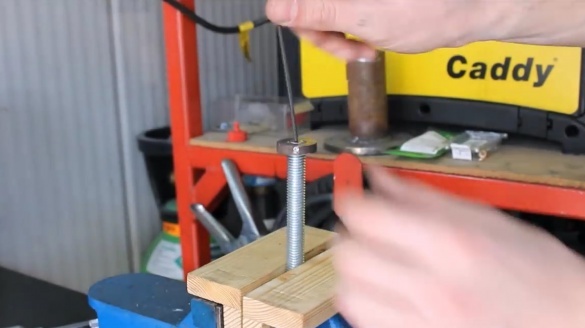

Taps the thread and tries on a hairpin.

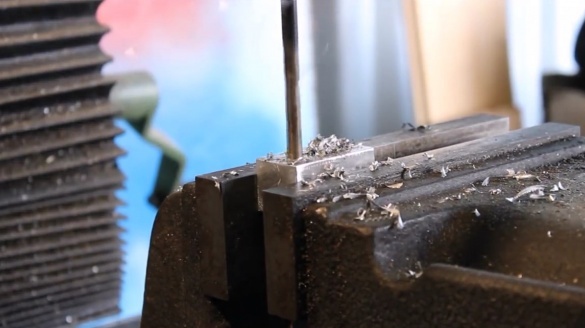

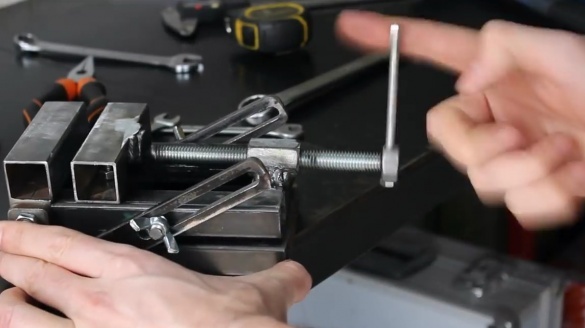

Starts making vise screw. Drills a thin hole in the end of the stud.

Then, having cut a thread in it, it bolts a thick washer with a bolt.

An elongated M10 stud is welded to the edge of the fixed base.

Now, having checked the accuracy of the stud and nut installation, it is welded to the movable jaw. After welding, grinds the seams with a grinder with a petal disk.

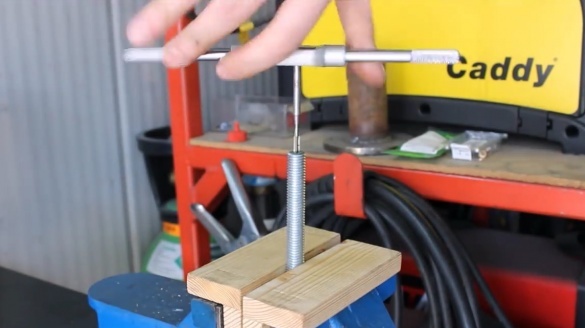

Having gathered everything together, he collects a "twist" for clamping a vise. He made it from a nut welded to the edge of a stud and a thin steel bar with a thread at the edges. Tightens nuts with wrenches.

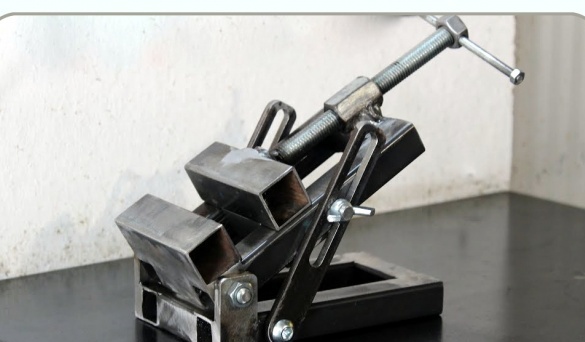

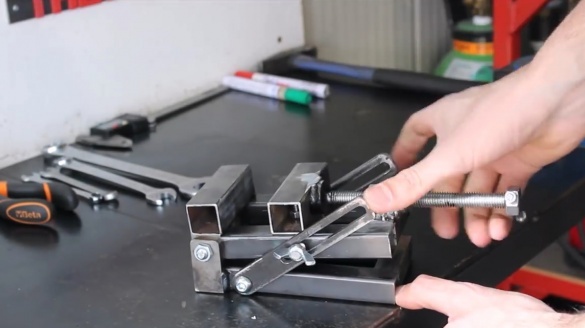

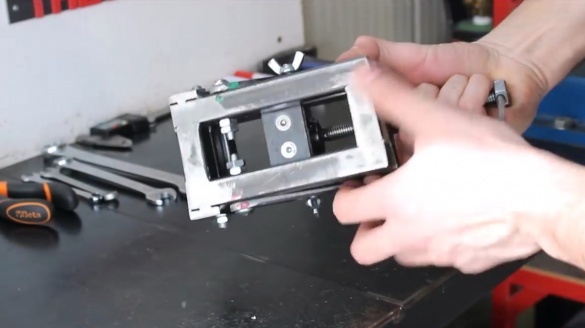

Now the device is ready! All parts move as needed.

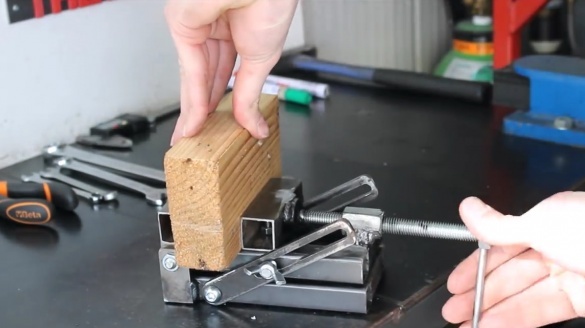

Now a little test. The author clamps a wooden block, and adjusts the angle of inclination, fixing it with screws - thumbs. And makes holes on the drill press at an angle. Everything turns out!

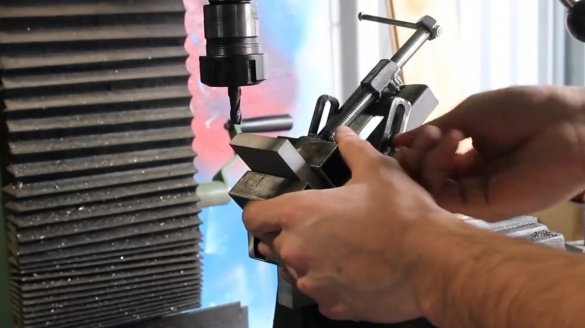

Now the task is more complicated. Mill the face of the steel plate at an angle using a movable table with a vise. The task was completed successfully.

Thanks to the author for a very interesting addition to the tooling of machines!

Good mood to you all!