This article will be interesting to everyone involved in welding. In it AndRey00001, the user of the Yaplakal site, will tell you how to make an interesting magnetic mass, which will simultaneously serve as a corner.

Materials

- Steel sheet 0.6 mm.

- A few neodymium magnets.

- A pair of scraps of wire

- Insulation tape

- Bolt, nut, washer.

Instruments, used by the author.

- Screwdriver or drill machine

- Welding machine

- Pliers, wrenches

- Vise.

Manufacturing process.

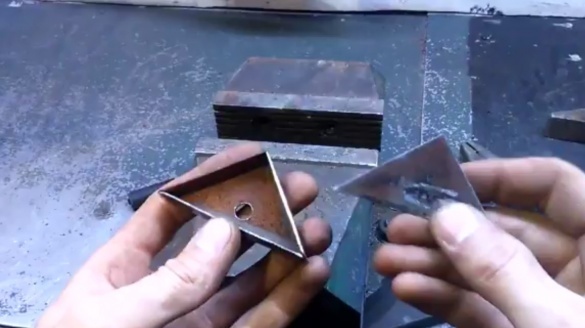

First, Andrei cut a triangle out of a steel sheet. And, holding it in a vice, he welded a piece of hairpin to its center. You can also use a bolt, welding it with a hat - there will be a larger contact area.

It turned out here is such a first detail.

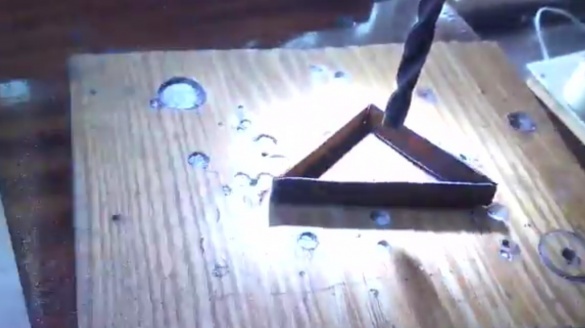

For the second part of the corner, the author bent such a triangle from the sheet. Using a drilling machine he made a hole for the stud.

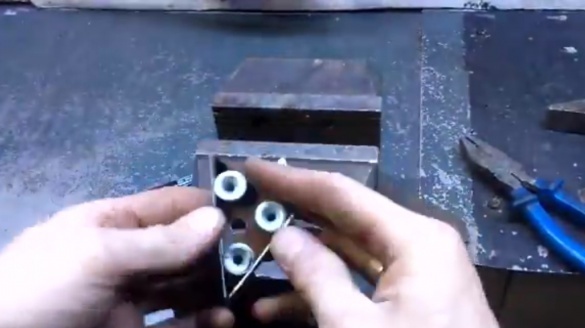

Now you need to install several neodymium magnets in the corners of the case, and just close it.

The edges of the body are not welded, but clamped with the help of such a trimmed washer.

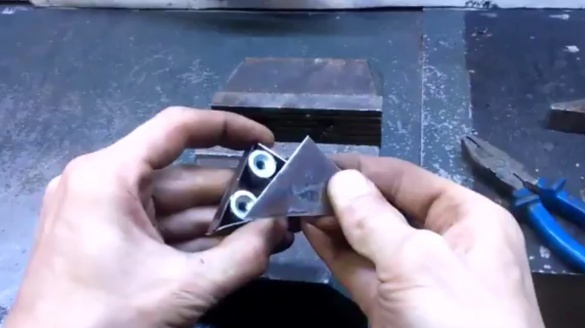

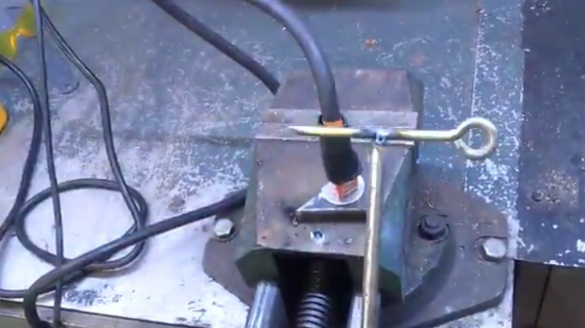

Andrey puts on the mass terminal of the welding machine and clamps it with a self-locking nut using a wrench.

For greater rigidity of the connection, it applies a pair of wire scraps, and insulates the terminal by wrapping it with electrical tape. Then puts on a rubber cambric.

Everything is perfectly magnetized.

The time for testing has come. Andrey turns on the inverter and checks the quality of the contact. The arc lights up on the first try. Tries to connect two unnecessary pieces of iron. The contact is just great.

Now welds a piece of pipe to the steel profile at 90 degrees. Everything is fine, even in the corner you can see.

And if the "crocodile" of the welding machine has nowhere to connect? It is enough to magnetize the mass onto the stripped section of the metal structure!

Thanks to Andrey for an interesting idea for the next version of the magnetic corner

The link to the original video is under the article, the "source" button.

Good luck to everyone and good tools!