This article will be interesting to everyone involved in soldering.

In it, Roman, the author of the YouTube channel "all ideas", will show how he made an infrared soldering iron from a car cigarette lighter.

Instruments, used by the author.

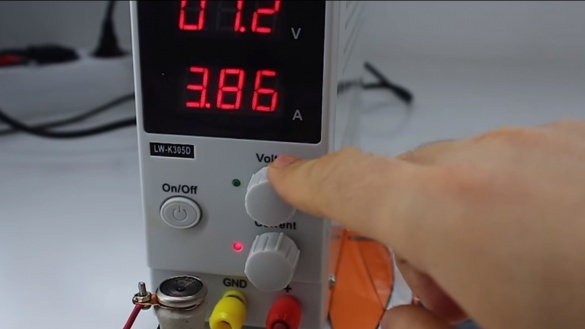

- Laboratory power supply

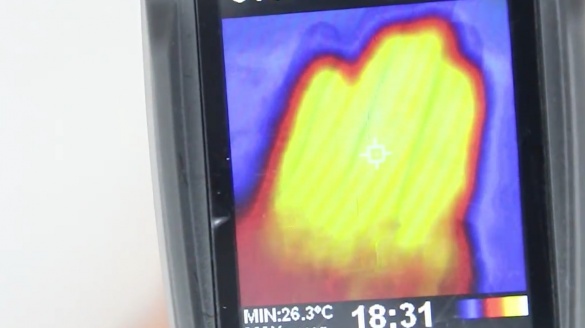

- Manual thermal imaging camera

- scissors

- Chisel

- Screwdriver, drill

- A screwdriver.

Materials

- Car cigarette lighter

- 0.5 mm thick copper sheet

- A pair of bolts, washers and nuts M3

- The wire.

Manufacturing process.

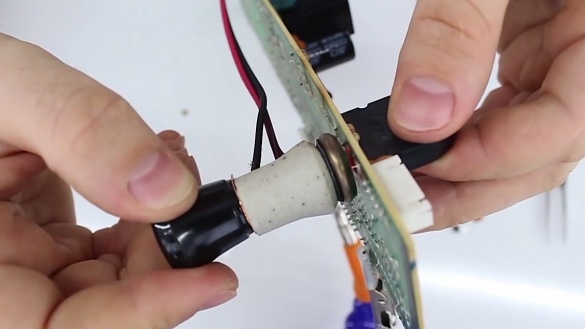

First of all, Roman parses the cigarette lighter.

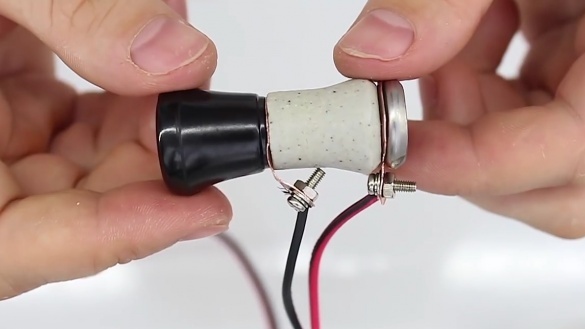

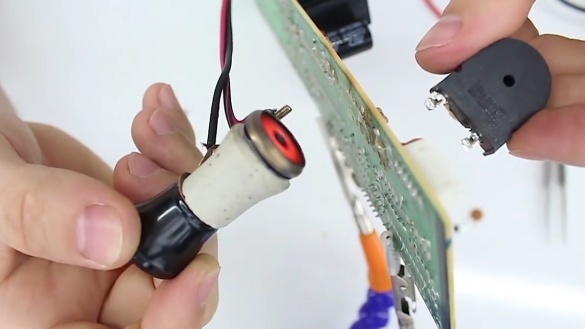

It is these details that are in the hands of the author, and will be needed for homemade work. It is a ceramic insulator and heater.

The cigarette lighter "decomposed" into such details.

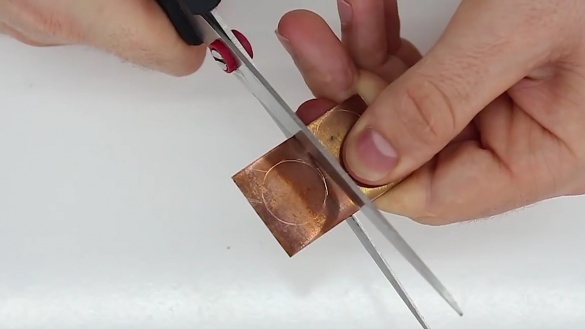

Then, on a copper sheet draws the contour of the heater, and cuts out the details.

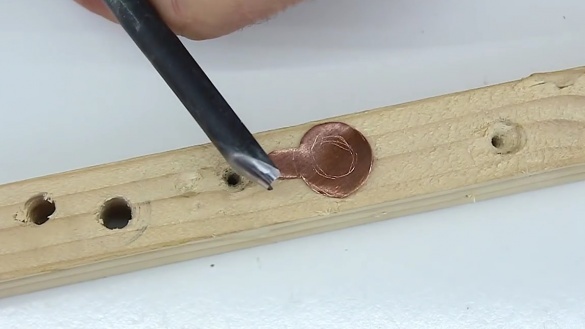

The first workpiece is the negative contact washer. The author did not find a suitable drill and he punched a central hole with a rounded chisel.

And with the plus, it turned out to be easier - he drilled holes with a screwdriver.

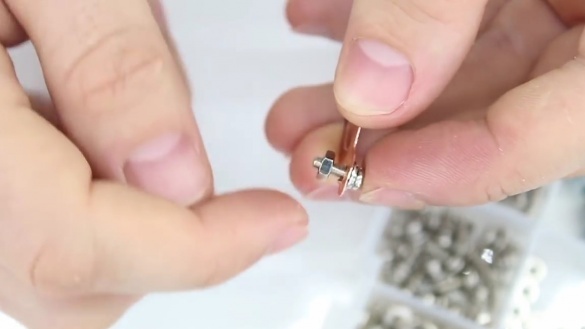

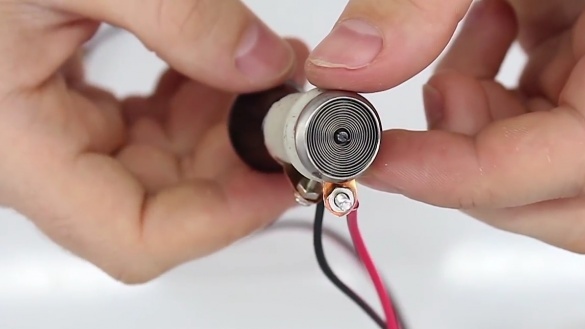

It is from these details that the soldering iron will be assembled.

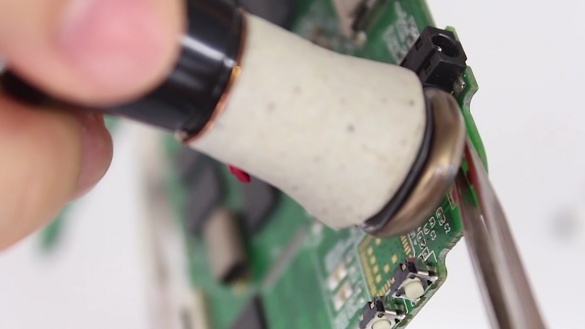

It makes a bolt, establishes a negative contact pad, puts on a ceramic insulator.

Further, he puts a positive contact pad on the central screw, tightens the nut and clamps the product with round-nose pliers (there were clearly no others).

Almost everything is ready, wraps the handle.

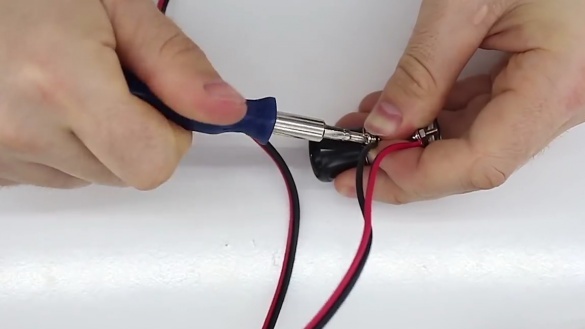

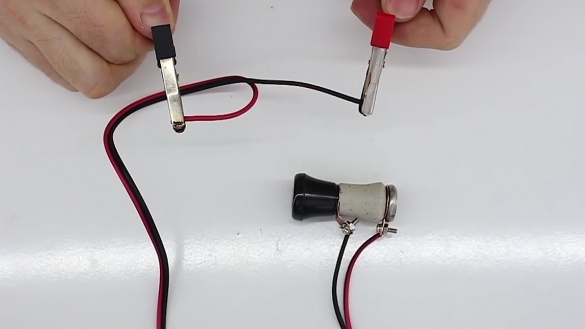

It remains to connect the power wires, clamps them with screws. Attention, the polarity of the Roman confused.

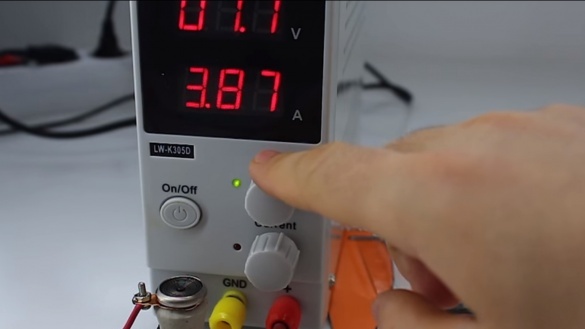

Here he has already corrected with polarity. Connects crocodiles to the power supply and sets a current limit of 3.85 Amperes. The voltage will adjust the power.

And now it's time to check what temperature this heater is able to give out. Voltage 12 volts, current 3.8 amperes.

To do this, Roma will check the capabilities of a thermal imaging camera. Maximum readings reach 301 degrees Celsius.

In this case, the spiral is not even very hot.

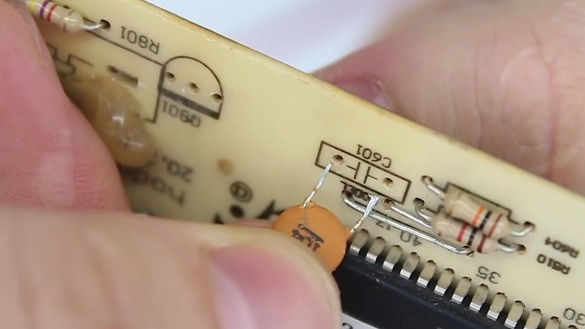

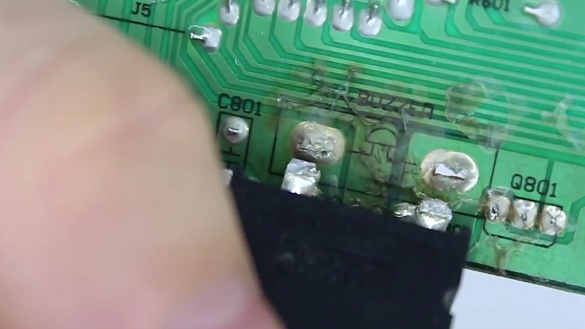

We must now verify in practice. There are no problems with SMD (surface mount) elements.

A small transistor and capacitor are soldered in a few seconds.

There is a slight yellowing of the flux residues on the circuit board.

And finally, "tweeter" with wide legs. Too fast enough

Thanks to Roman for an interesting idea for homemade work! Soldering the details is excellent, but the author never showed how he solders the solder.

Links to the thermal imaging camera and power supply - the author has a video.

All good ideas and good mood!