Hello to all lovers of barbecue, barbecue and fried meat. I suggest to make do it yourself a very simple design of the barbecue grill from the drum of a washing machine, front-loading automatic machine, for home and outdoor trips. The drum from the front-loading machine is needed because the top-loading drum has doors for loading laundry that are not needed. Many will say - where to get such a drum, because not everyone has a disassembled washing machine with the right drum. Everything is very simple, if you have the opportunity to get to the scrap metal collection point, then there is a lot of this stuff, different configurations and such penny drums are worth it.

Materials and consumables

1. Front-loading washing machine drum

2. Rivets or screws with nuts M4, M5

Tool

1. Bulgarian and cutting wheel

2. Welding (semi-automatic, arc, argon or spot)

3. The hammer

4. Drill and drill

Step One: Cut the Drum

We remove all excess from the drum and cut off the loading neck at the place of docking with the drum.

Next, mark the drum and cut it in half with a grinder so that we get two identical halves.

We also divide the neckline in half and cut the grinder into two parts.

Step two: connect the halves of the drum

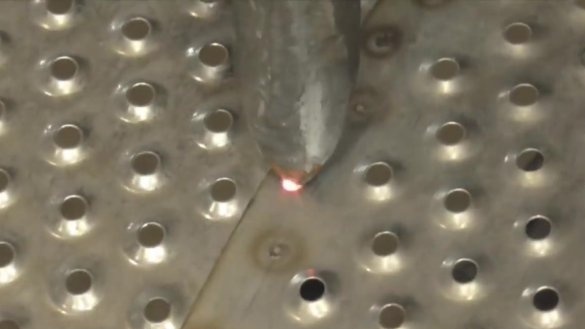

Now you need to connect the two halves of the drum into one solid structure, and for this purpose, the author used spot welding, the fastest and most reliable way.

Those who do not have spot welding were a little less fortunate, but this task can also be handled by having a simple arc welding (using a stainless steel electrode), a semiautomatic device or argon-arc welding. And finally, everyone has an affordable way to connect using M4, M5 bolts or rivets. We drill holes of the required diameter for the rivet or bolt, and rivet the rivets, or screw the bolt with nuts, forming a strong connection.

Step Three: Attaching the Feet

The legs for the barbecue are made from the element of the loading neck and they need to be attached to the side walls of the barbecue.Due to the connecting seams on the drum, the legs will not stick tightly to the base. We solve this problem with a hammer, simply bending the docking seam on the drum in or out, forming a flat surface for the legs.

To fix the legs, the author also used spot welding. All those who do not have such a tool can use any method available to you described above.

Brazier is ready, and you can already experience it

Standard skewers are just suitable for the barbecue and this is good news.

Because of the holes in the drum, there will always be enough oxygen to burn your coals and wood.

All delicious kebabs and bon appetit!

Video: