Hello everyone, I propose to consider a very interesting grinder based machine that you can make do it yourself. It will allow fairly evenly cutting large sheet material and not only. The working disk is easily adjustable in depth, which will allow you to cut along the pipe, make cuts in sheet material and more. The author also quite easily cuts square pipes at an angle, that is, the machine also works like a pendulum saw.

The machine is arranged very simply, it consists of a carriage, which moves along a square steel pipe. Bearings act as rollers, and most of the machine frame is made of square steel pipes. Let us consider in more detail what such a machine can do and how to assemble it!

Materials and tools used by the author:

Material List:

- square steel pipes;

- a square steel pipe of large diameter (the carriage will ride along it);

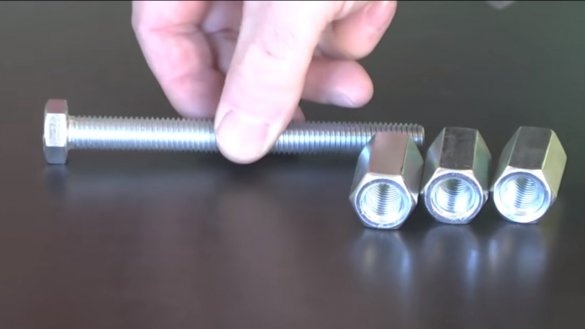

- nuts and bolts;

- Sheet steel;

- 16 bearings (used as rollers);

- washers;

- grinder

- paint.

Tool List:

- welding machine;

- drill;

- grinder;

- clamps;

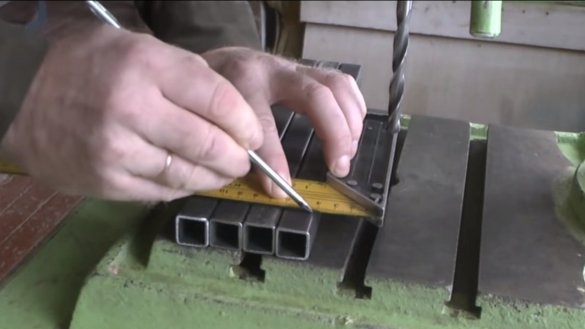

- marker, tape measure.

Manufacturing process homemade:

Step one. Carriage Making

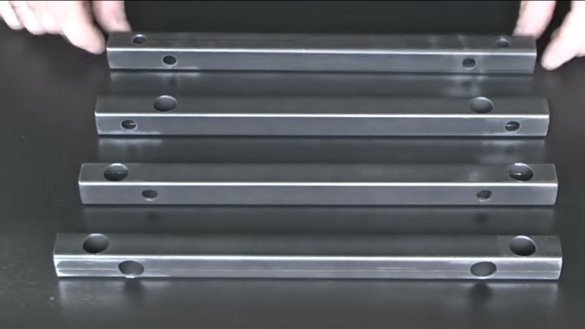

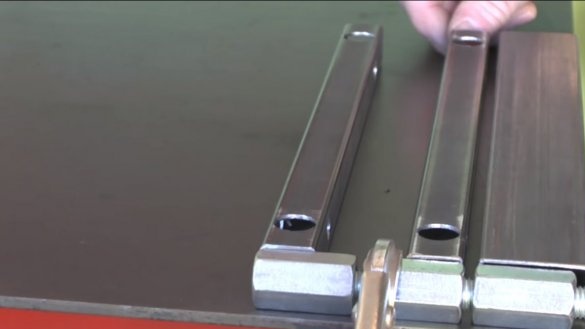

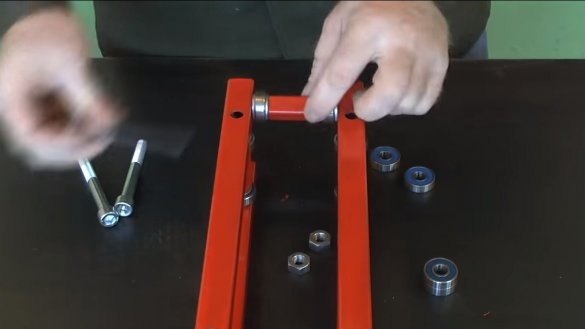

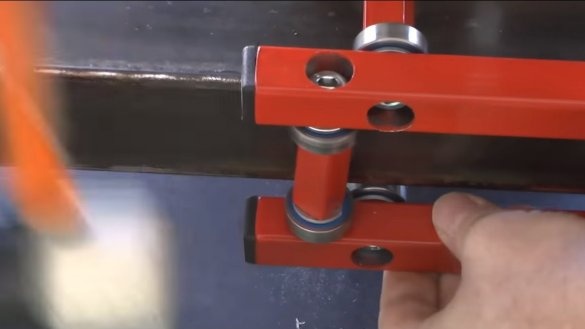

Our carriage will ride on a steel square tube on rollers, which are bearings. The backlash of this unit must be minimal, otherwise significant deviations during cutting can occur. And so that there is no backlash, it is advisable to assemble this unit directly on the guide, choosing the desired length of the spacer or washer. But in general, it is desirable to make the node adjustable. The main parts of the carriage are four pieces of a square steel pipe.

Bearings are mounted on screws and tightened, spacers made of square pipes are installed between the bearings. We install washers on each side of the bearing.

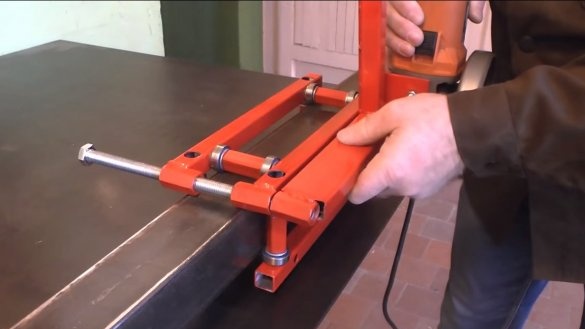

Step Two Bracket for grinder

The grinder we have will be mounted on a lever that is pivotally attached to the carriage, it can rise and fall above the working area.We weld this lever from a square steel pipe, and to attach the grinder to the lever, we weld two plates with holes. We will fasten it with bolts from two sides, where the handle is mounted. As for the handle, it is mounted on the machine for conveniently moving the carriage forward and backward.

To adjust the lever in height, a nut is welded to it and a bolt is screwed in, which abuts against the carriage. By turning the bolt, you can fine-tune the depth of cut.

Step Three Painting and testing

To make the machine look good and not rust, paint it with metal paint. That's all, our machine can be assembled and tested.

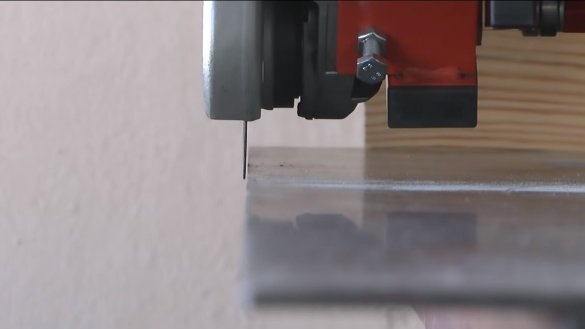

To begin with, the author decided to cut along a square steel pipe, the pipe is attached to the table with a clamp. The machine easily coped with this task.

Further, the author tried to cut the pipe at an angle, and the machine also perfectly coped with this task.

That's all, the project is over, the machine showed itself perfectly in business, and it is going to be quite simple. I hope you enjoyed your homemade work, good luck and creative inspiration, if you decide to repeat it.