When working with pipes, the most important problem is to bend them. Someone is trying to use sand, someone is warming up the bend, but the easiest way to do this is with a special small stanochka. He will bend the pipe quickly, efficiently and with minimal effort. During experiments, the author bent easily out of a steel pipe bicycle steering wheel using a homemade machine.

It is not difficult to assemble such a machine, it consists of a jack, a special pressure head and a frame that can be welded from a corner. The hydraulic jack is best suited for such purposes, as it is convenient to work with it. If you are interested in the machine, I propose to consider in more detail how to assemble such a machine.

Materials and tools used by the author:

Material List:

- corner;

- hydraulic jack;

- Sheet steel;

- two strong steel rods;

- paint for metal;

- Three pancakes for a dumbbell.

Tool List:

- welding machine;

- grinder;

- belt sander;

- vise;

- drill with drills.

Manufacturing process homemade:

Step one. Press head manufacturing

One of the most important organs of the machine can be considered a pressure head, it is installed on the stem of the jack and it is thanks to it that the pipe bends as intended. To make this head itself, the author decided to use pancakes from a dumbbell. In total, pancakes need to be cut so that three parts are obtained. In the central part of the head, a recess is machined, into which the pipe enters. This groove is first cut through the grinder with a cutting disc, and then we select the excess metal with a petal disc.

All parts must be very reliably welded to each other. The first experiment with the author was unsuccessful, the details were twisted with bolts and the whole structure crumbled. If you wish, you can make heads for different pipes, for different diameters. They do not attach to the rod, they simply install on it.

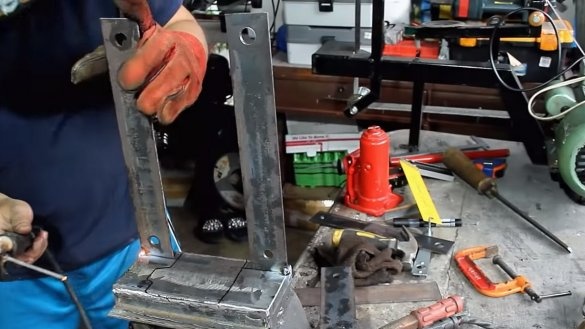

Step Two Frame manufacturing

If the head is made, then we will only have to make a frame.It should be quite strong, as a material, a steel corner is well suited. The base is made of thick sheet steel and strengthened as much as possible, a jack will be installed here.

The frame also has special stops for the pipe, they are fixed on the axles and are movable. As the pipe bends, these stops change their angle and hold the pipe at all stages of bending. Such stops can be made from a square tube of a corner and so on.

The rods are best taken from strong steel, as an example - pieces of valves from a car engine or similar carbon steel.

Step Three Machine testing

We proceed to the tests, the first experiment with the author failed, the head fell apart, as it was poorly welded, and he twisted it with bolts. Pancake metal can be difficult to weld and can be brittle, so the author had to weld everything again. Boil the head to be as reliable as possible.

Well, further tests showed that the machine turned out to be successful and copes with its tasks perfectly. The author easily bent the steel pipe, as a result, he got an excellent bicycle steering wheel.

That's all, the project is over, it turned out successful and I hope you liked the idea. Good luck and creative inspiration, if you decide to repeat it. Do not forget to share your ideas and homemade things with us!