Hello everyone, I present for consideration a very simple and very useful machine that you can make do it yourself. It is a kind of “mechanical arm” on which various equipment can be installed. As an example, the author installed a hand-held circular saw and a milling cutter on the machine. Using the device, you can easily cut materials, perform milling, and more. “Hand” is able to be adjusted in height; for simplicity, it is equipped with an electric motor with a gearbox that raises or lowers it to the desired height.

For the manufacture of the machine, the author used available materials. For example, swivel joints are made of bicycle wheel hubs. Thanks to this design, we get durability and accuracy, the bearings can be tightened, thereby removing the play in them. The frame is assembled from a profile pipe, corner and sheet metal. If you are interested in the machine, I propose to consider in more detail how the machine is going to!

Materials and tools used by the author:

Material List:

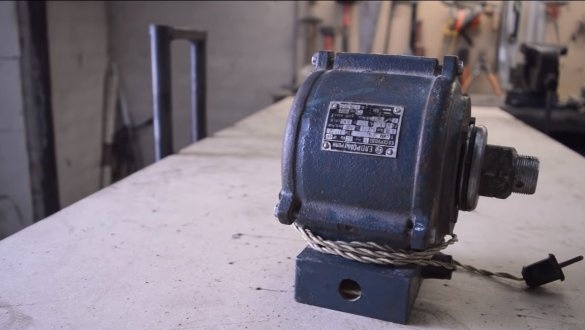

- 180 watt engine or the like;

- reduction gear 1k20;

- threaded rod and nuts;

- profile pipe (rectangle and square);

- corner;

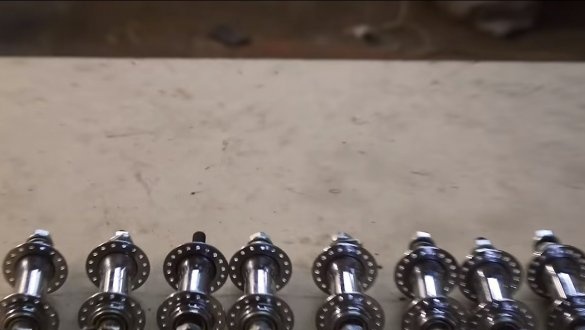

- bicycle bushings (9 pieces);

- round steel pipes;

- plywood or the like (for countertops);

- screws with nuts;

- socket;

- cable;

- paint for metal.

Tool List:

- tape measure and marker;

- grinder;

- welding machine;

- vise;

- drill.

Machine manufacturing process:

Step one. Table making

For the manufacture of the machine we need a table, in general, it can be screwed to the wall and make a small table. But in our case, the author makes a large desktop, on which in addition to this machine there are two more grinding machines. All we need to do is weld a sturdy steel frame of suitable sizes. The author uses shaped pipes as a material. When the structure is assembled, we check it for strength and install the overlap. As a worktop, an OSB sheet, plywood or other durable sheet material is suitable.

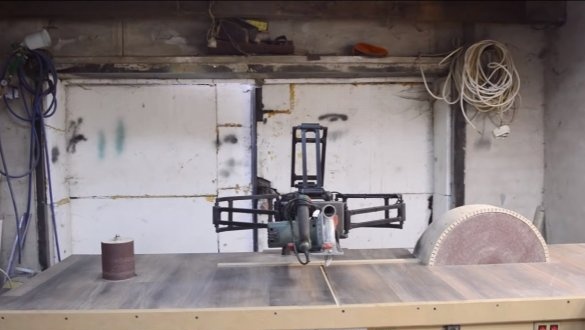

Step Two Lifting gear

Next, proceed to the assembly of the lifting mechanism. To begin with, we will assemble a frame that will rise and fall, its author welded a rectangular shape from round pipes. For this frame we produce clamps, they are welded to the table frame.For the manufacture of such clamps, the author used round pipes of the same diameter as in the manufacture of the lifting frame. In total, you need four pieces that need to be cut along. Next, we weld two nuts to each fixture and wrap a bolt so that the fixtures can be pulled together and set minimum clearances. In one of the nuts we drill a thread. Then the pipes will need to be lubricated so that they move easily through the guides.

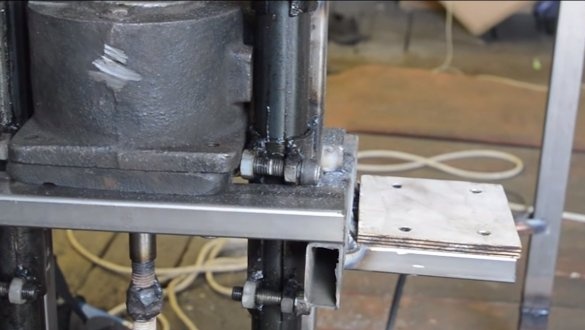

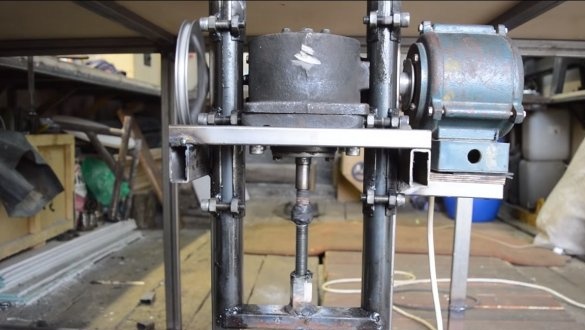

Next, we need to install a device that will raise and lower the frame of the machine. To do this, we need a reduction gear and an engine. The author has a rather weak engine, only 180 watts, but it is enough if you use a gearbox with a gear ratio of 1:20. The motor shaft is directly connected to the gear shaft. The gearbox and motor are fixed motionless on the table frame.

We weld a threaded rod to the reduction shaft, and weld a nut to the movable frame so that when the shaft rotates, the frame rises or falls. This mechanism can be seen in more detail in the photo. That's all, lubricate the pipes, threaded rod and try to turn on the engine. Of course, the engine must have a reverse so that the frame can not only be raised, but also lowered.

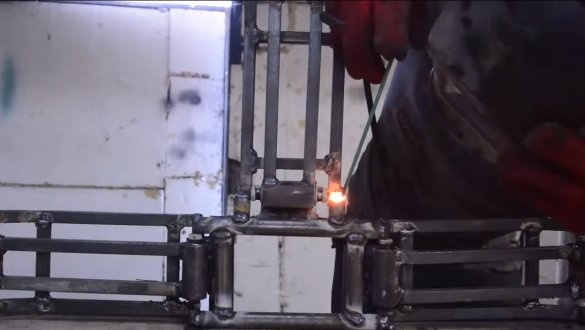

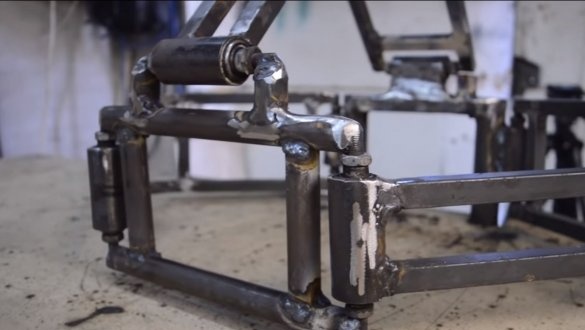

Step Three Swivel Fabrication

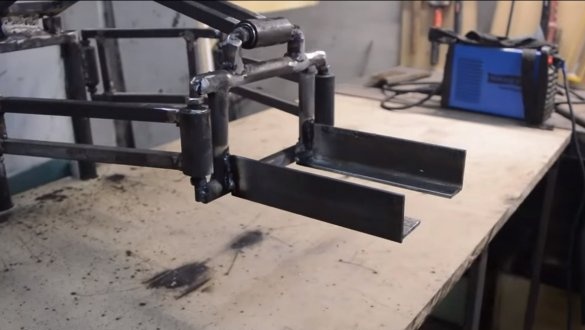

For the manufacture of articulated joints, we need 9 bushings from bicycle wheels. First, we remove from them those parts that are needed to install the spokes. Next, the bushings must be installed in steel tubes so that machine parts can be welded to them. The tubes must be selected with a suitable diameter. The author cuts the pipes along, sets the sleeves, and then, holding the tubes in a vise, welds the slots with welding. We clean the welds with a petal nozzle and we have excellent durable joints.

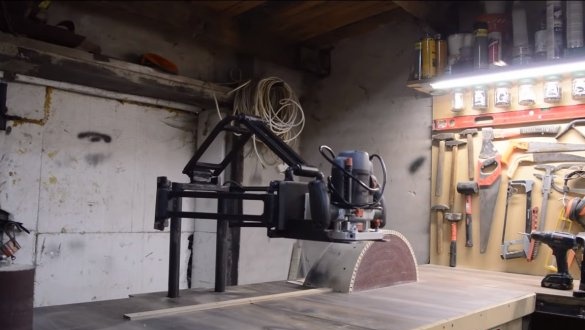

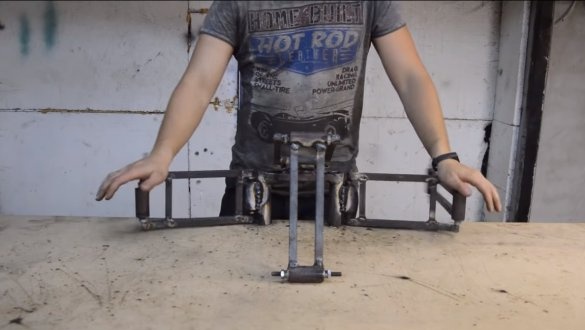

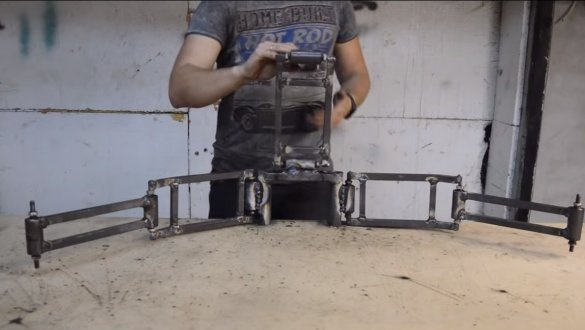

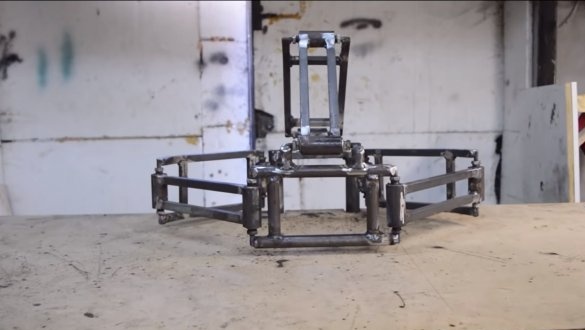

Step Four Making hands and assembling the machine

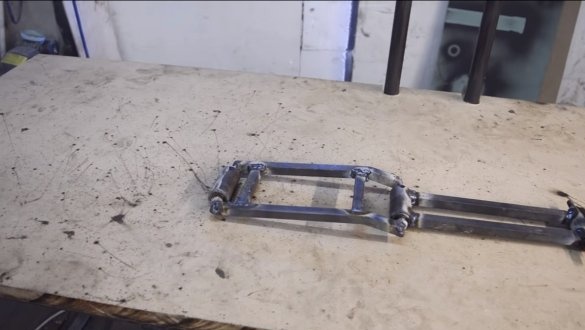

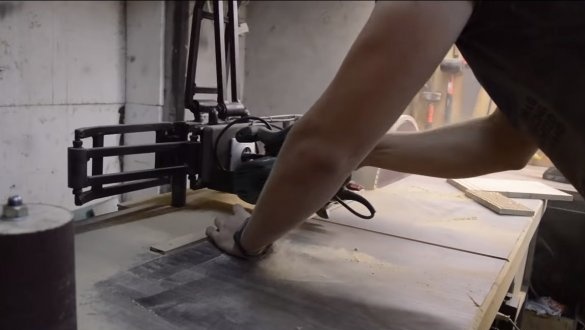

To make the “hands” of the machine we need square pipes. We weld out three of them, as the author has in the photo, two side and one upper. They should be the same shape and size. Set the “hands” on our rising frame, weld them behind the axis of the bushings. We install on the unused sides of the axles of the spacer so that the entire structure is rigid and strong.

As for the other ends of the “hands”, we need to combine them by attaching to a frame welded from pipes.

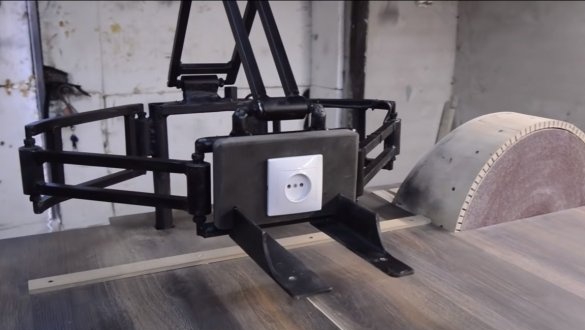

Step Five Mounting bracket

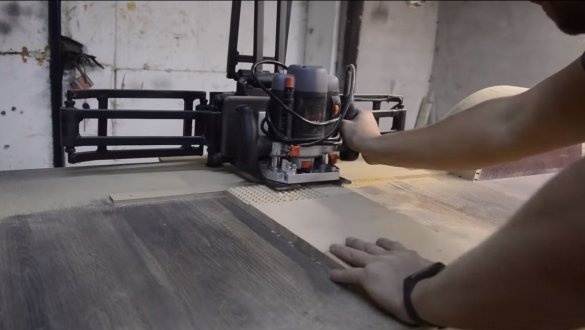

We install a mounting bracket on the machine for installing various tools. The author welds two corners, a milling cutter and a circular saw will be installed here. For ease of use, we draw a cable through the machine and install a socket opposite the mounting bracket. It is also advisable to equip the machine with an emergency switch.

Step Six Final touches and testing

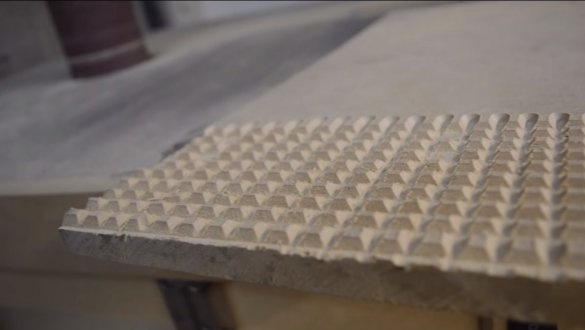

At the end, we cover the steel parts of the machine with soil and paint so that the machine does not rust. That's all, we can proceed to the tests. The author installed the milling cutter and in a couple of minutes cut an interesting picture on the fiberboard plate.

And if you install a circular saw, a number of cuts can be made on the material, which will then allow it to be bent into a semicircle. Of course, with the help of the machine you can deal with the sawing of materials.

In addition, the author installed two home-made grinding machines on his desktop.

That's all, the project is over, I hope you liked it! Good luck and creative inspiration, if you decide to repeat it.