This article will be of interest to many masters. Some of you probably had to use flat steel tape clamps. This is a very cheap and reliable method that allows you to attach even large diameter parts, such as anther. This method is also used when packing large boxes.

In it, the author of the YouTube channel "George Kosilov" will tell you how to make a reliable tape clamp using available materials. Its design is very simple, and by changing the dimensions of the structure, you can choose the base for the required tape width.

Materials-

- Aluminum profile pipe 14X14, and a length of about 75 mm

- Steel cotter pin

- Two furniture bolts for mounting handles

- Steel tape for clamps.

Instruments, used by the author.

- Screwdriver, drill

- Kern

- Vise, hacksaw

- Ruler, scissors

- File.

Manufacturing process.

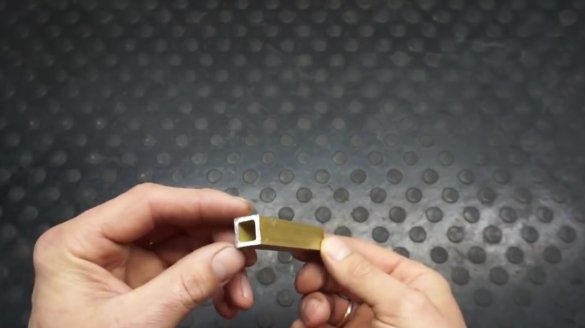

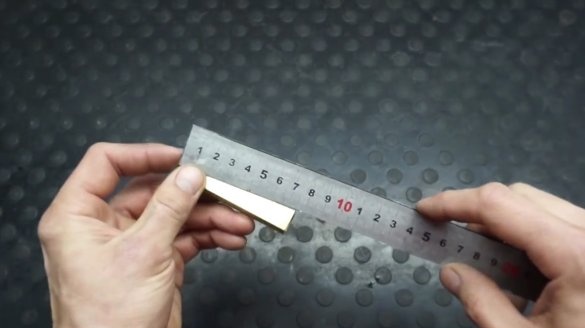

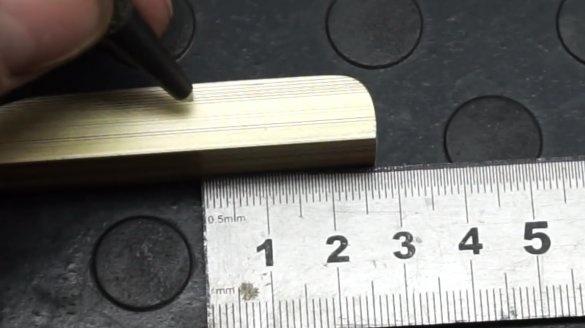

The author took a square aluminum profile measuring 14X14X75 mm.

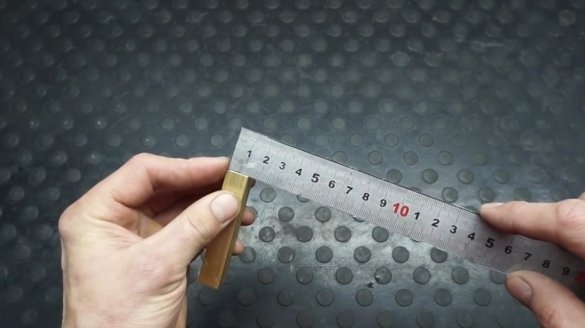

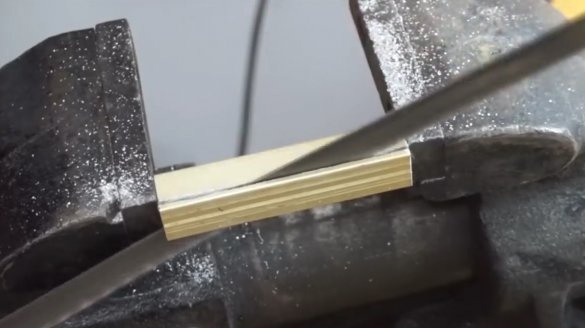

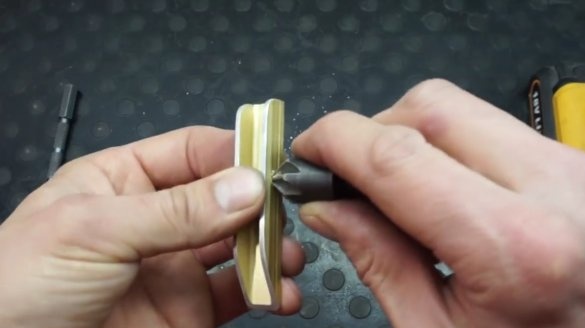

Then from this profile you need to make a U-shaped. It fixes the workpiece in a vice and cuts one face with a hacksaw.

It also cuts the two edges of the workpiece.

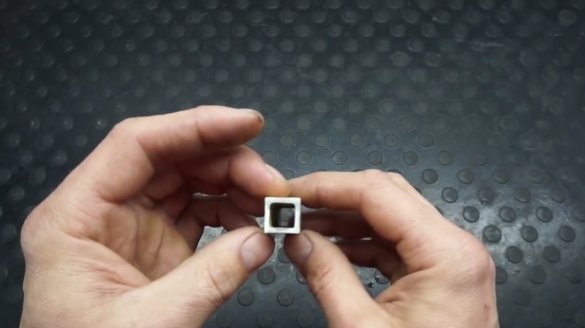

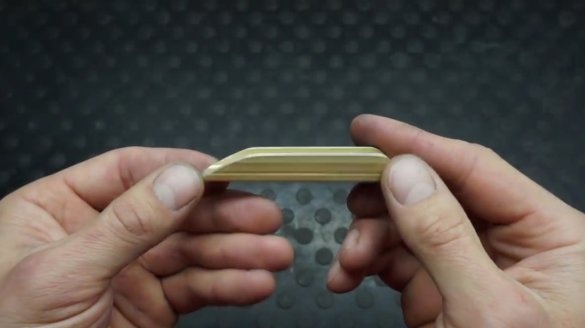

After processing with a file and sandpaper, this is the base of the clamp.

At a distance of 25 mm from the rounded edge, the author turned and drilled a hole.

Then he drilled a hole to a diameter of 4 mm, and chamfered using a countersink nozzle.

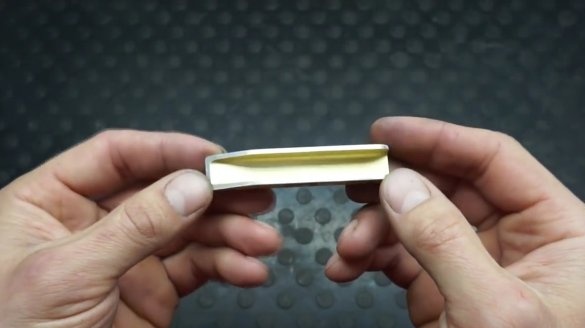

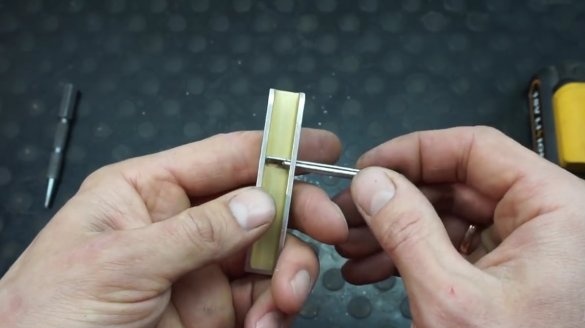

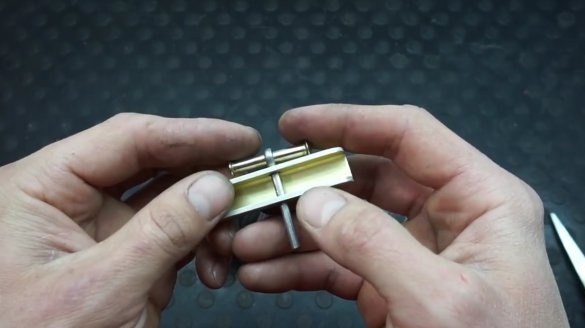

As a tensioner fixtures the author will need a cotter pin, he will cut off both its edges at the same length.

And as a collar a pair of furniture bolts will do. From a single bolt leaves only the pin, cutting it, and two elongated nuts. He passes the pin into the cotter pin loop and tightens the nuts.

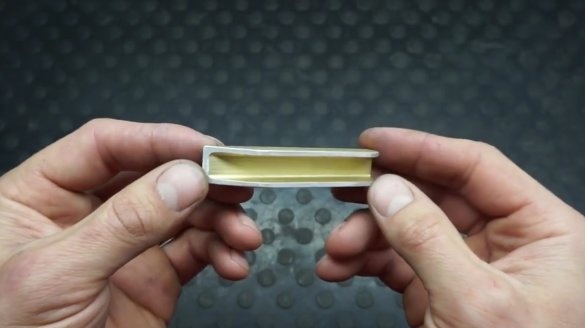

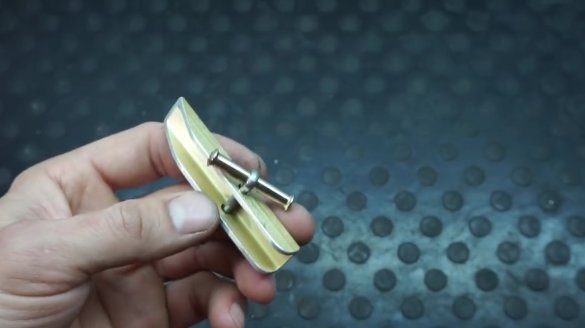

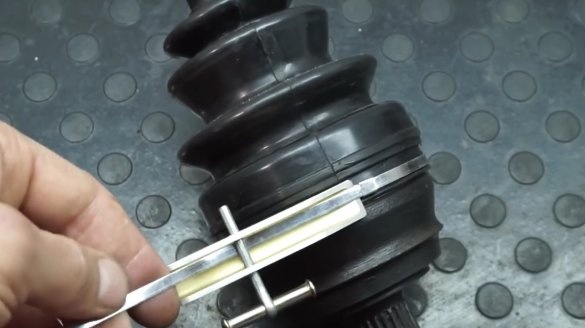

This is how the finished clamp and steel tape look. The width of the tape may vary.

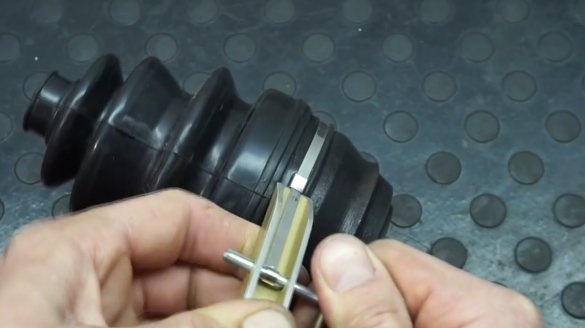

It's time to test, and explain how it works. The author makes two turns of the tape, and passes through the loop. After that, it winds the edge of the tape into the slot of the cotter pin.

Having cut off the excess tape, it simply rotates the knob, and the tape is pulled, twisting on the cotter pin.

He bends the tape, turning the clamp, and pulls out the cotter pin.

Once again, cuts off the excess tape and presses the bending point with a hammer.

Here is such a clamp. It can be made simply, quickly and practically from trash.

Thanks to the author for the original and simple version of the clamp!

All a good mood and reliable connections!