This article will be of interest to many motorists and craftsmen who often have to loosen nuts and bolts.

In it, the author of the YouTube channel George Kosilov will tell you how he made a universal extension for open-end wrenches from a steel strip and a bar. Such a homemade product does not take much time.

Materials

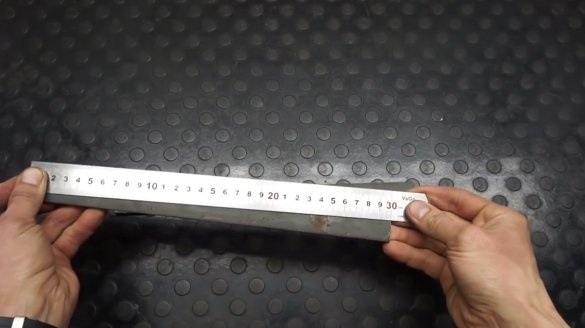

- Two pieces of steel strip with a length of 300 and a width of 25 mm

- Washer 25 mm

- Two nuts M10

- Steel bar with a diameter of 6 mm

- Spray paint.

Instruments, used by the author.

- Welding machine

- Grinder, cutting disc, flap disc

- Screwdriver

- Ruler, vernier caliper

- Kern

- Vise.

Manufacturing process.

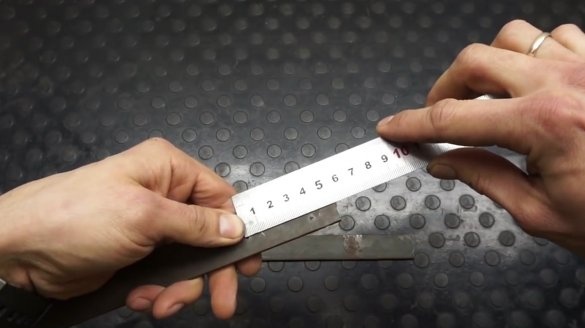

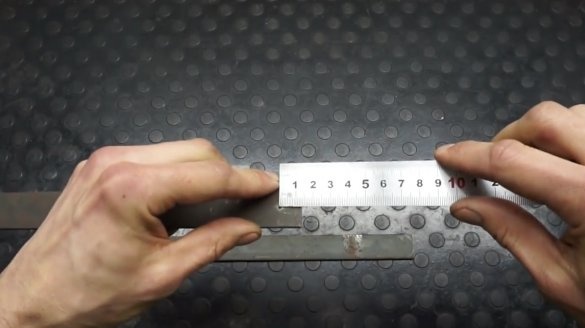

To begin with, the author needs to make the marking of the necessary holes on the blanks from a steel strip 300X25 mm using a core.

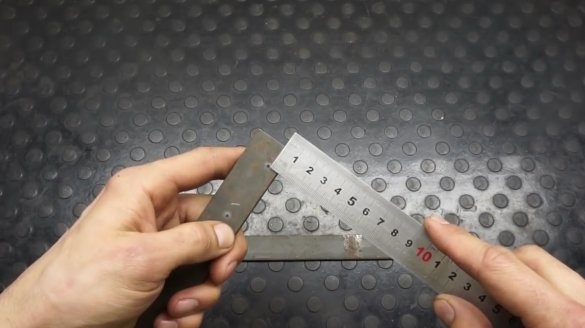

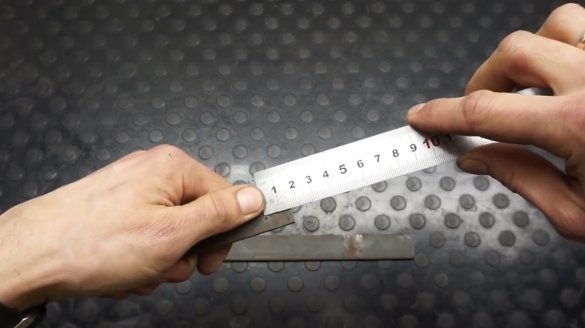

The marking has already been done, he will show it to you - the first hole is 8 and 15 mm.

The second hole will be 11 mm 55 mm

And in the back of 12 to 12, in the center.

Then the author takes a metal washer with a diameter of 25 mm to attach, and encircles it along the edge of the core. Then on the emery it will be necessary to cut off these edges so that they are rounded.

So, first drills holes with a diameter of 6 mm, clamping the workpiece in a vice. It is advisable to clamp both at once, for a more exact match of the holes.

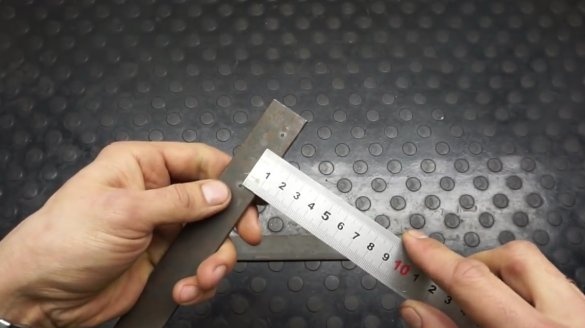

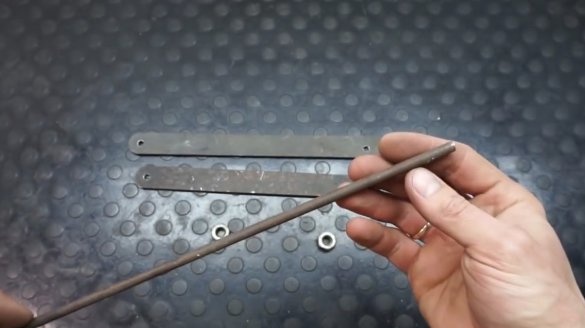

Next, you need to round the corners, first part cuts with a grinder, polishes the rest.

The blanks are ready, now you need two M10 nuts, and a steel bar with a diameter of 6 mm.

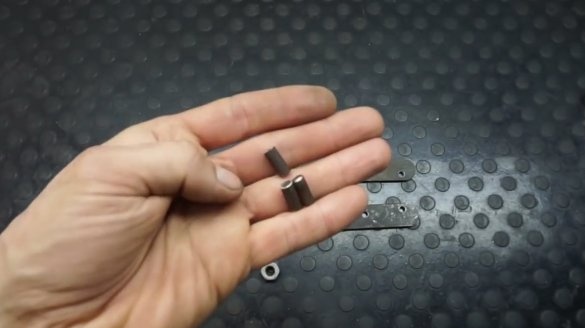

I cut three pieces of a bar 14 mm long.

It remains to assemble it all together, put nuts and covers with a second blank. The author specially made the bushings smaller so that they slightly deepened into the strip, thus ensuring high reliability of the weld and the appearance of the product.

Boils bushings on both sides.

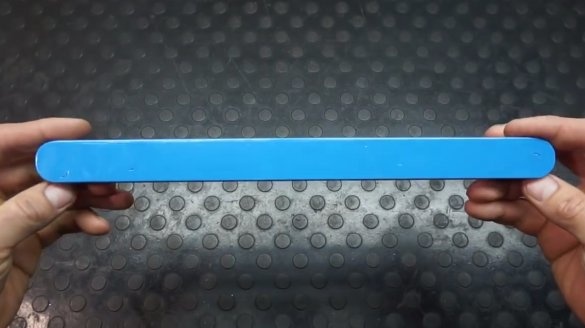

As a result, we got such a design, now the author will clean these points and paint the instrument with spray paint.

This turned out to be such an incomprehensible tool at first glance.Pretty, painted on what is it?

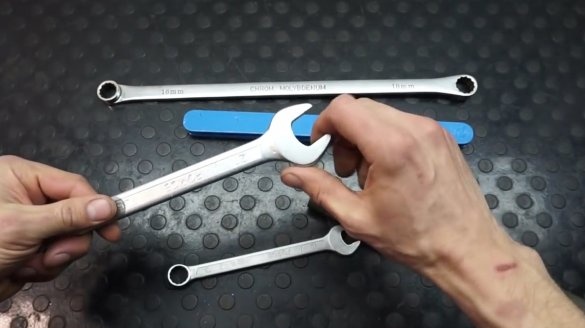

There are places in which it is difficult to climb, and you need to make a lot of effort in order to unscrew the bolt or nut. We can only insert a horn wrench there, but when you don’t have enough effort, this already causes a problem.

For such things, there are such large elongated keys. You see what a difference there is between them; it is almost twice as long.

But what to do when you do not have such a long key, but do you need to unscrew? We take a new device and insert the open-end wrench here. The force, accordingly, comes out even more than the elongated key.

If you adhere to the dimensions indicated by the author, then the key is that you can insert it, deploy it, and insert it with the other side. You will still have a relatively flat line.

You can use large keys, smaller keys - the tool itself is universal.

You, of course, say that you can take a piece of pipe, put on the key and unscrew. You get an incomprehensible, and uncomfortable design, in which there is a high probability of breaking off one tooth.

In the proposed tool, the emphasis is on the key itself, and the second emphasis is on the tooth. Accordingly, the load is distributed more evenly. In this way, you unscrew any nut. The author believes that with such an effort any nut or bolt will surrender.

Thanks to the author for an interesting and useful extension cord, and recommendations for repeating it!

I wish you good luck and good mood!